A reinforcement method for exhaust pipe of integrated stove

A smoke exhaust pipe and integrated stove technology, which is applied in the field of integrated stove accessories, can solve the problems of unsmooth smoke exhaust, vibration and falling off of the smoke exhaust pipe, etc., and can flexibly adjust the inclination angle, increase the contact area, and avoid natural drooping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

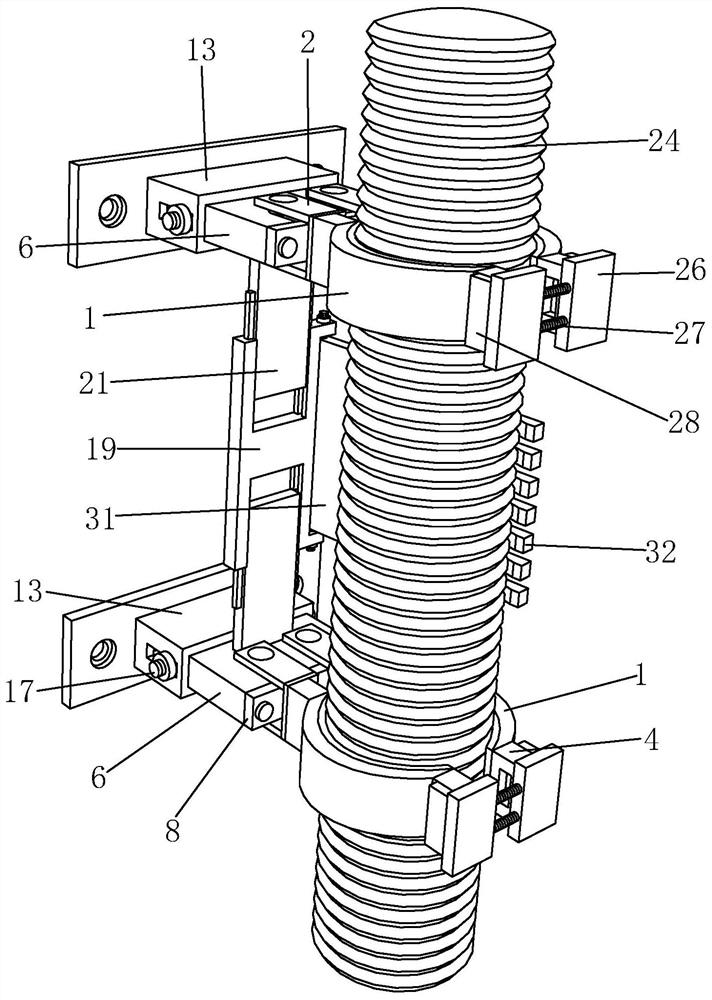

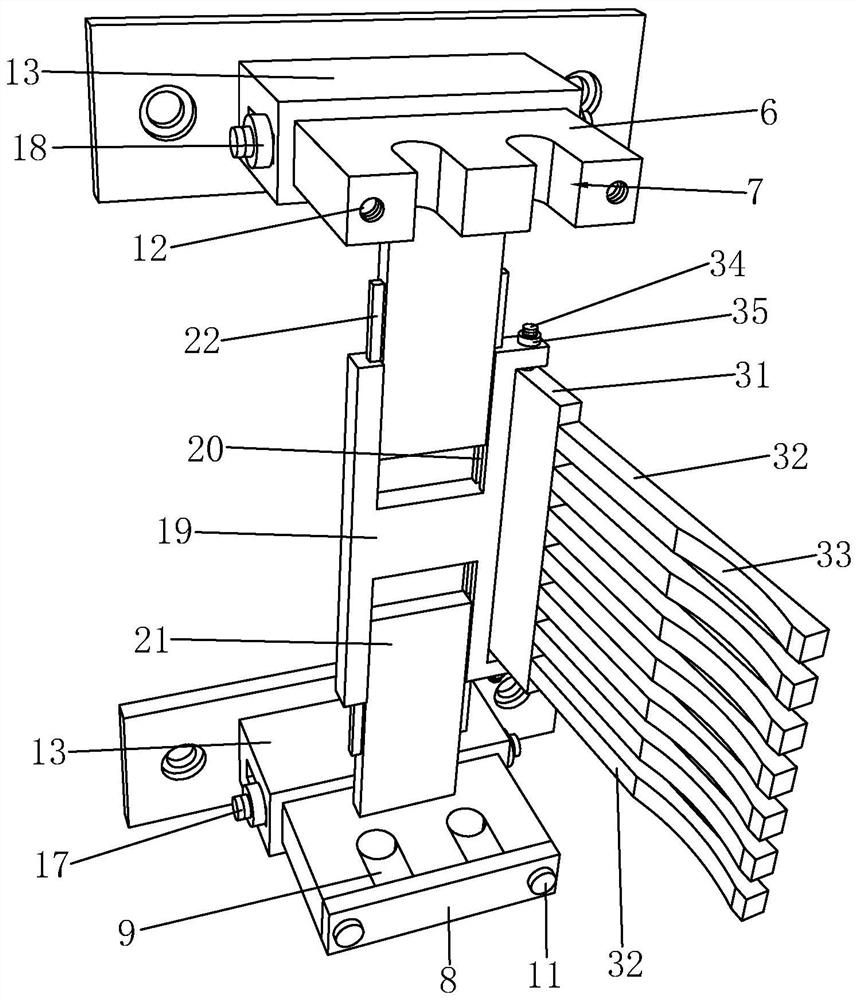

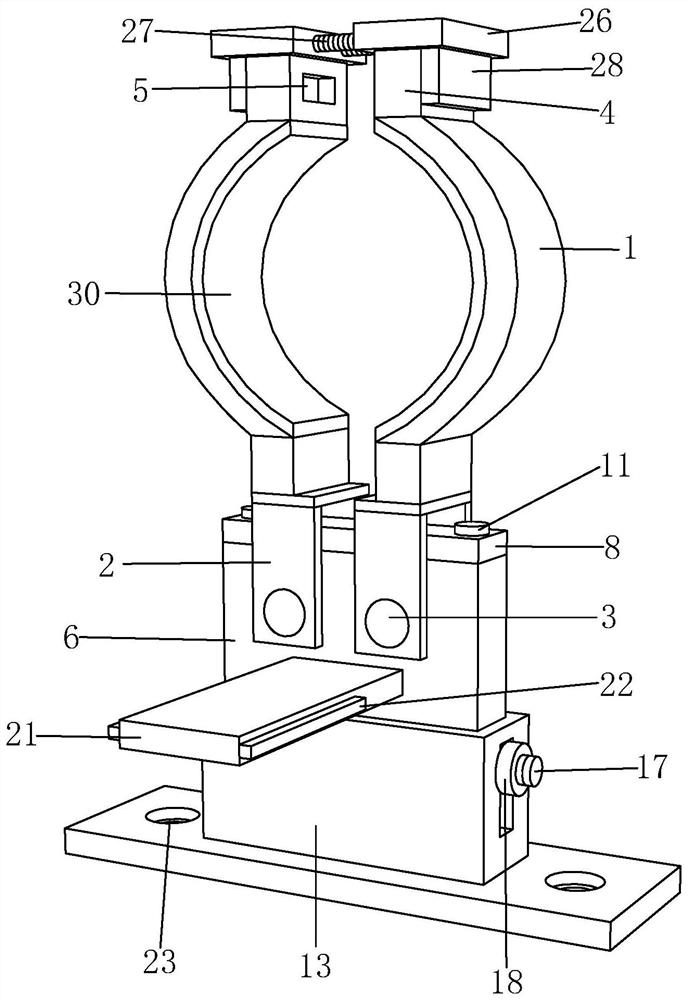

[0036] Such as Figure 1 to Figure 7 As shown, it is a method for reinforcing the exhaust pipe of an integrated stove according to the present invention, which includes the following steps:

[0037] (a) Support part assembly:

[0038] One end of the arc splint 1 is provided with a U-shaped fixed block 2, and the U-shaped fixed block 2 is provided with a fixed shaft 3, and the other end of the arc splint 1 is provided with an end block 4, and the end block 4 is provided with a fixed through groove 5, Opening grooves 7 are symmetrically distributed on the support base 6, and the opening grooves 7 correspond to the fixed shaft 3. Limiting blocks 9 are symmetrically distributed on the fixing plate 8, and the limiting blocks 9 correspond to the opening grooves 7. The limiting blocks 9 An arc groove 10 is provided at one end thereof, and the arc groove 10 corresponds to the fixed shaft 3 .

[0039](1) The two arc-shaped splints 1 are placed symmetrically, and the fixing plate 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com