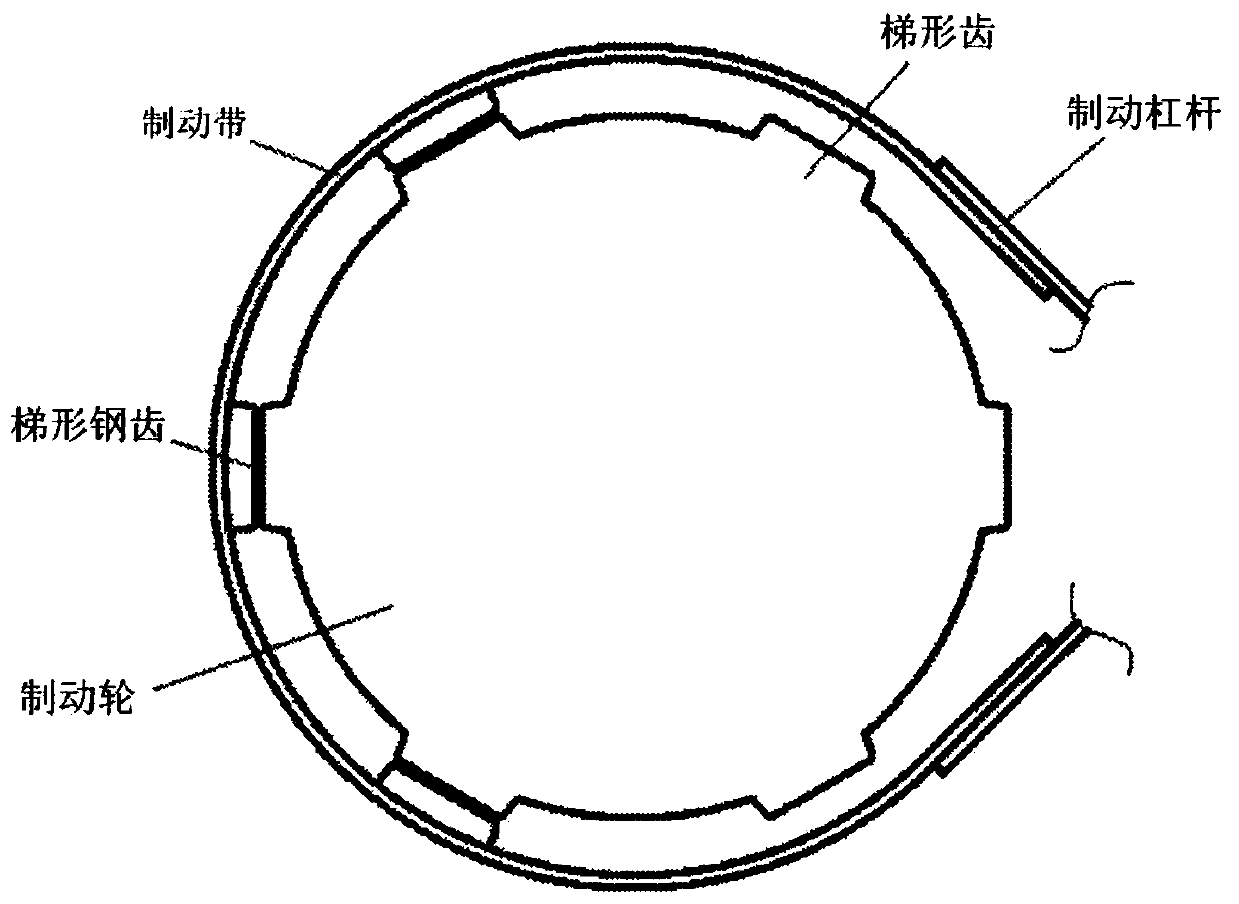

Externally holding belt type tooth form brake

A technology of brake and tooth shape, which is applied in the field of vehicle transmission system, can solve the problems of endangering the strength and life safety of meshing steel teeth and their connection structures, and increasing the force of meshing teeth, so as to avoid a large amount of heat and burnout, improve transmission efficiency, Effect of System Weight Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

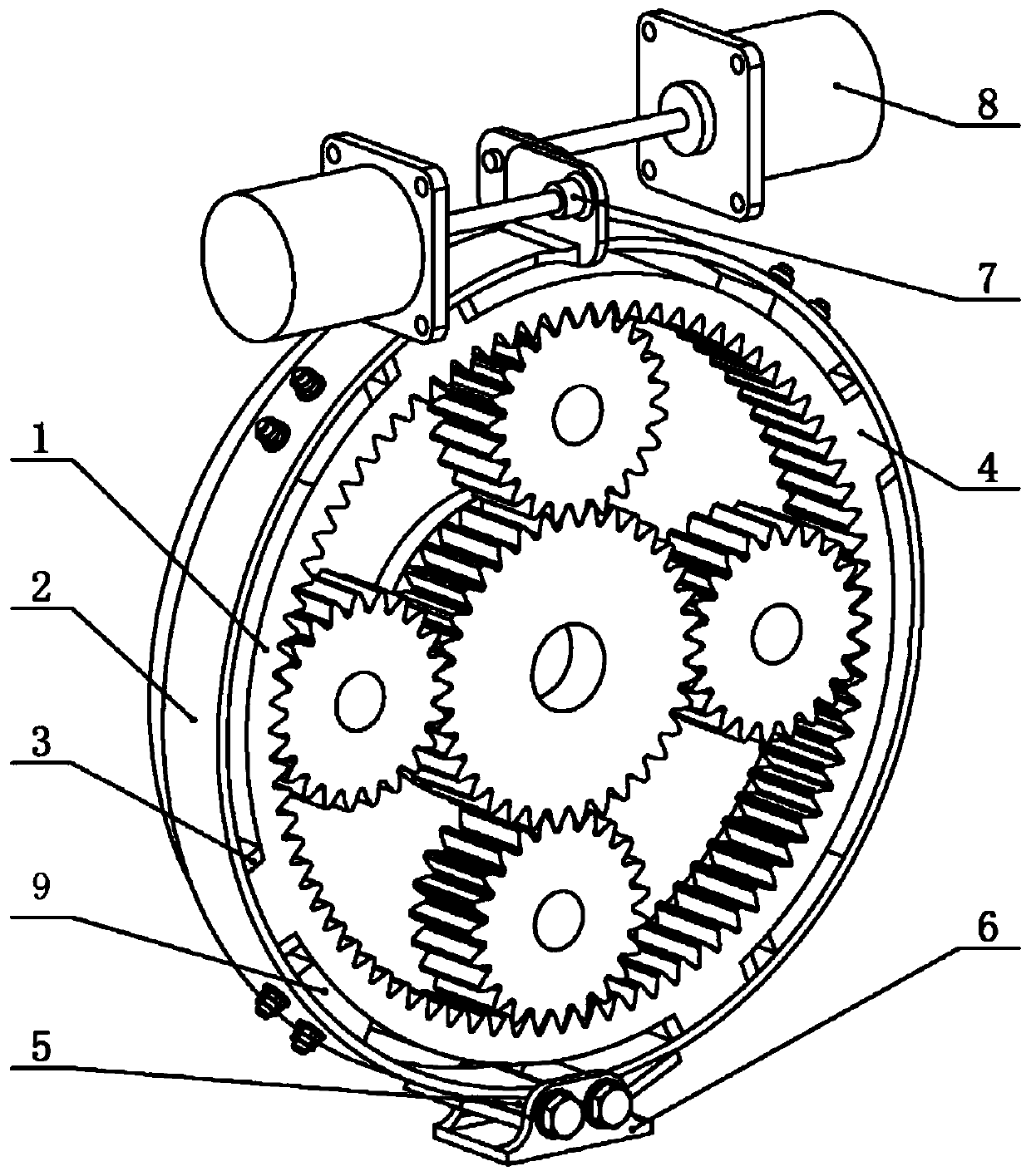

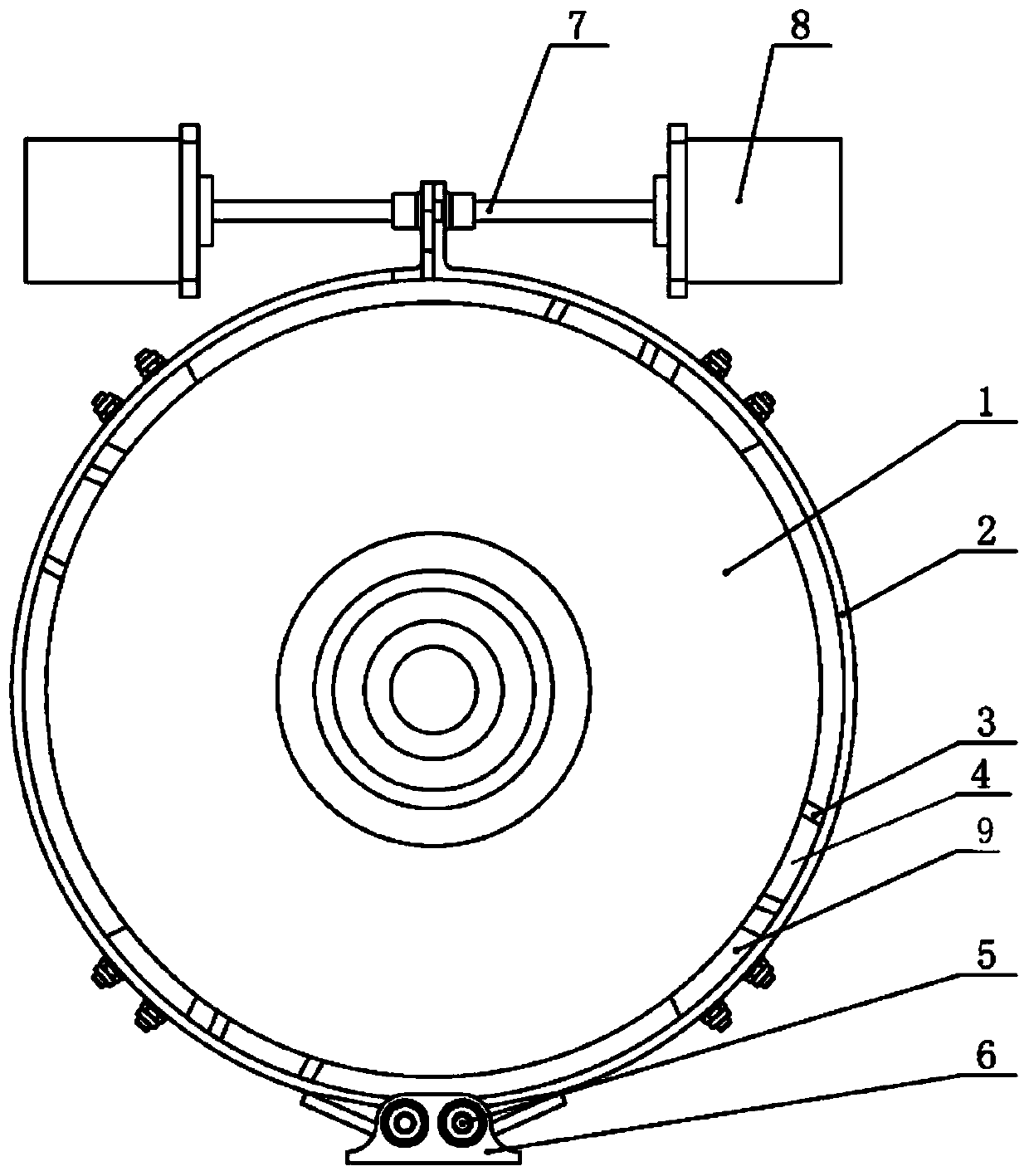

Method used

Image

Examples

Embodiment 2

[0040] On the basis of the above-mentioned embodiment 1, an external hanging point is welded on the movable end of the brake band 2 to add a return spring, which helps the steel teeth to disengage smoothly when the brake ends, so that the brake band 2 can be separated quickly. One end of the return spring is connected to the external hanging point on the outer surface of the brake band 2, and the other end is connected to the external fixed support. The axial direction of the return spring is parallel to the axis of the screw nut assembly 7. When the two brake bands 2 are combined When in the braking state, the return spring is stretched, and when the braking ends, the two braking bands 2 are assisted to separate under the action of the restoring force of the return spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com