Explosion-proof fan with detachable connection parts

An explosion-proof fan and connecting part technology, which is applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of single installation method, unable to meet installation requirements, unable to meet the fixed installation of axial flow fans on vertical wall plates, etc. , to achieve the effect of convenient connection and various installation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

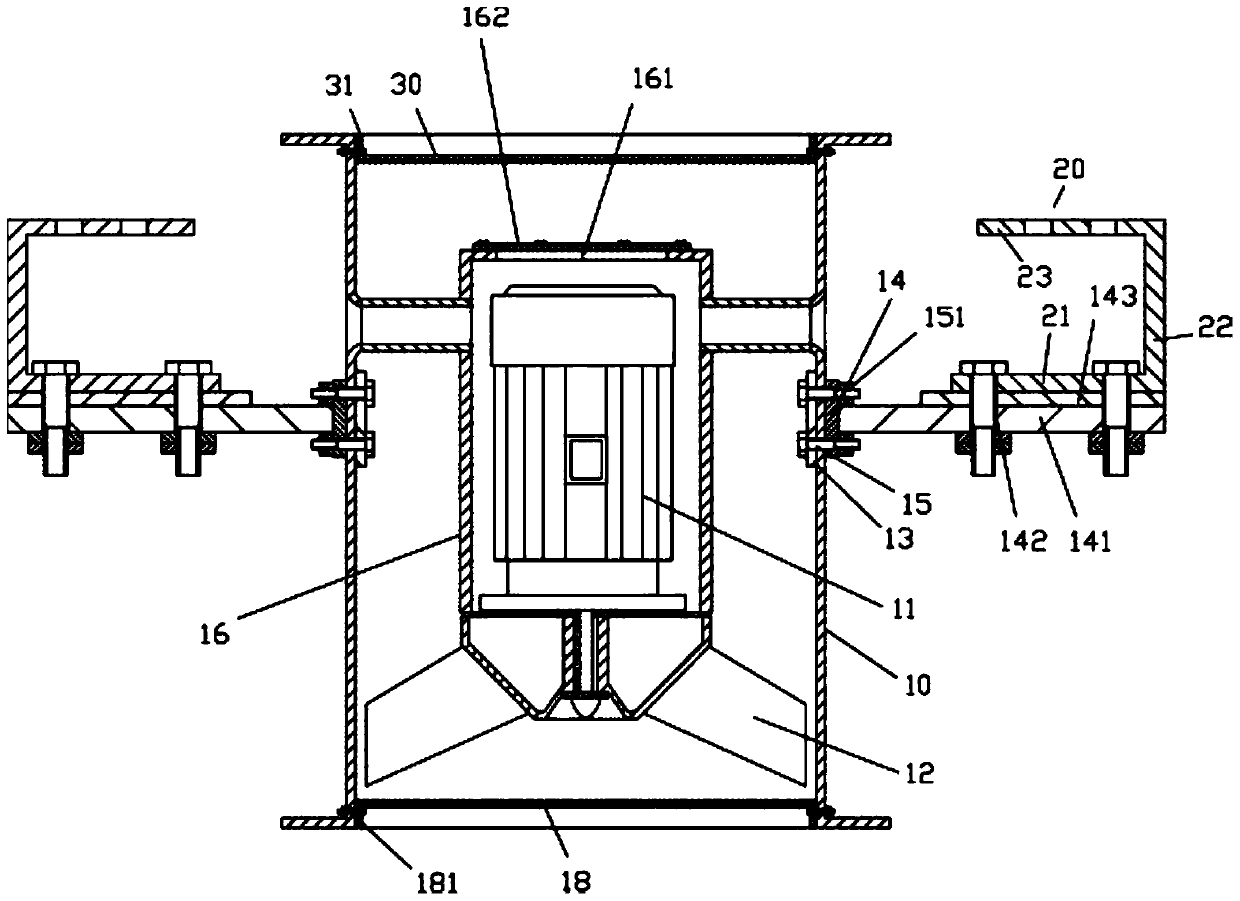

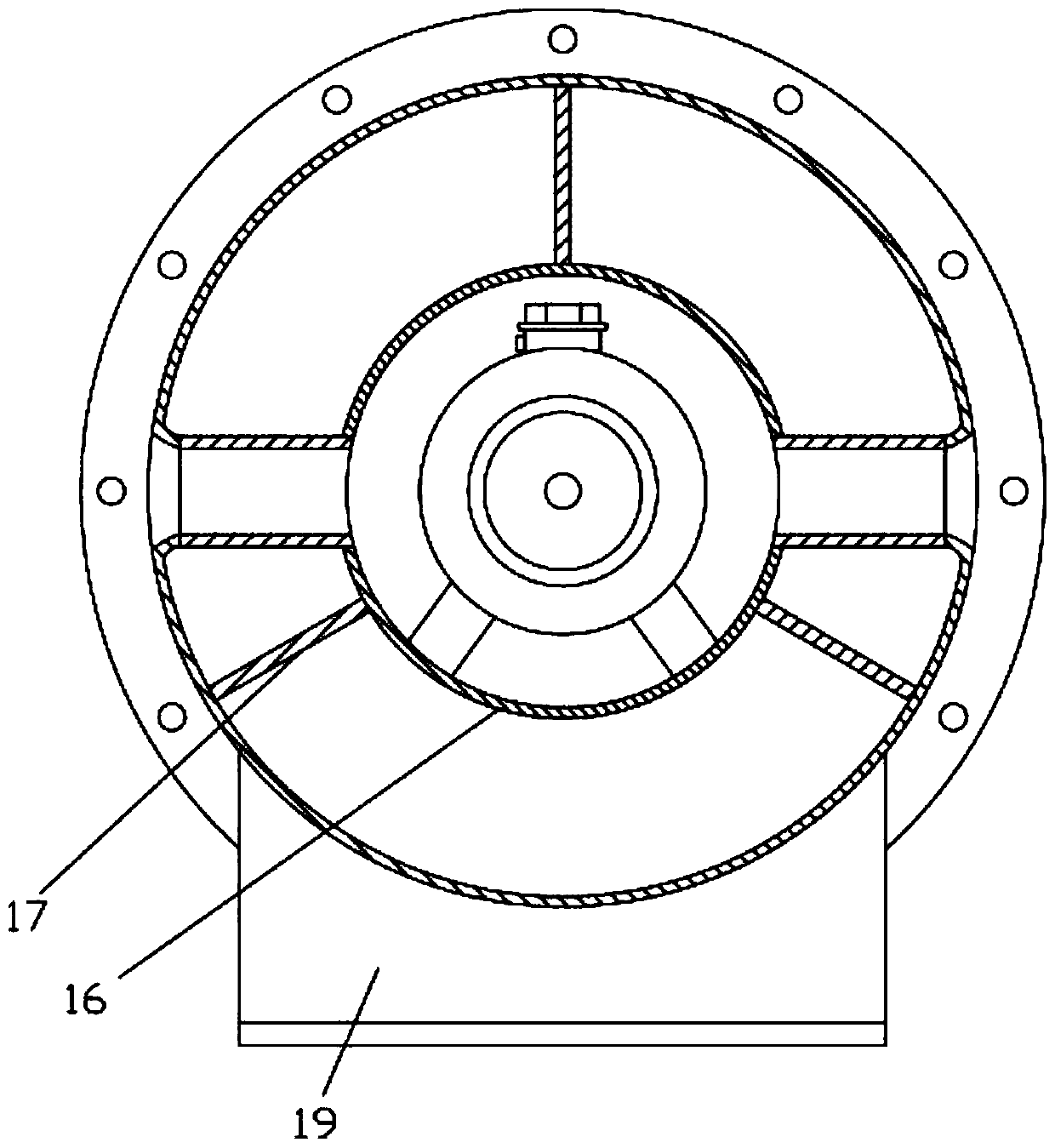

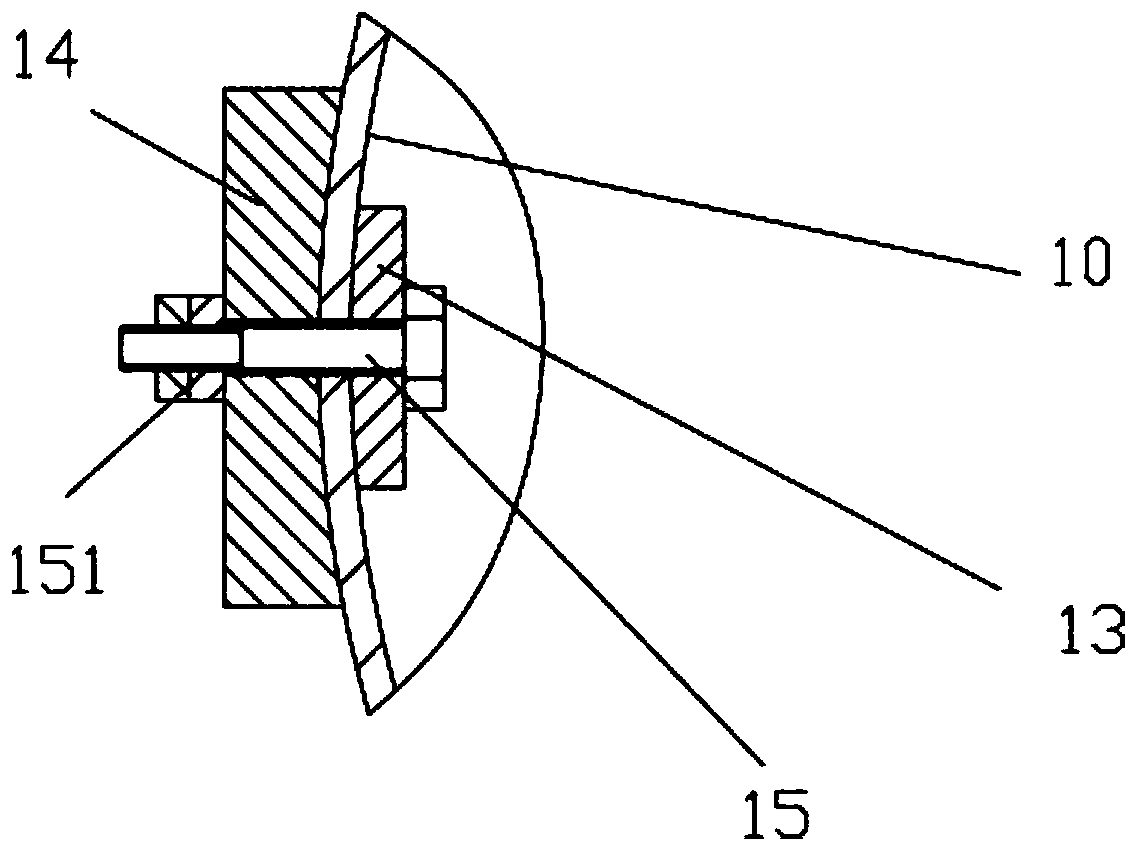

[0020] Examples, see e.g. Figure 1 to Figure 3 As shown, an explosion-proof fan with a detachable connection part includes a main air cylinder 10, an explosion-proof motor 11 is arranged in the middle of the main air cylinder 10, and an impeller 12 is fixed on the output shaft of the explosion-proof motor 11. The main air cylinder 10 The inner connecting plates 13 are all pressed against the inner side walls of the wall plates on the left and right sides of the main air duct 10, and the outer connecting plates 14 are all pressed against the outer walls of the wall plates on the left and right sides of the main air duct 10, and the inner connecting plates 13, main The wall plate of the air duct 10 and the corresponding outer connecting plate 14 are connected and fixed by fixing bolts 15;

[0021] A connecting elongated plate 141 is fixed on the outer wall of the middle part of the outer connecting plate 14, and a connecting through hole 142 is formed on the connecting elongate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com