Exhaust hoods for industrial gas compressor

A technology for industrial gas and compressors, which is applied in the direction of liquid variable displacement machinery, mechanical equipment, machines/engines, etc., and can solve the problems of poor noise reduction and simple structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

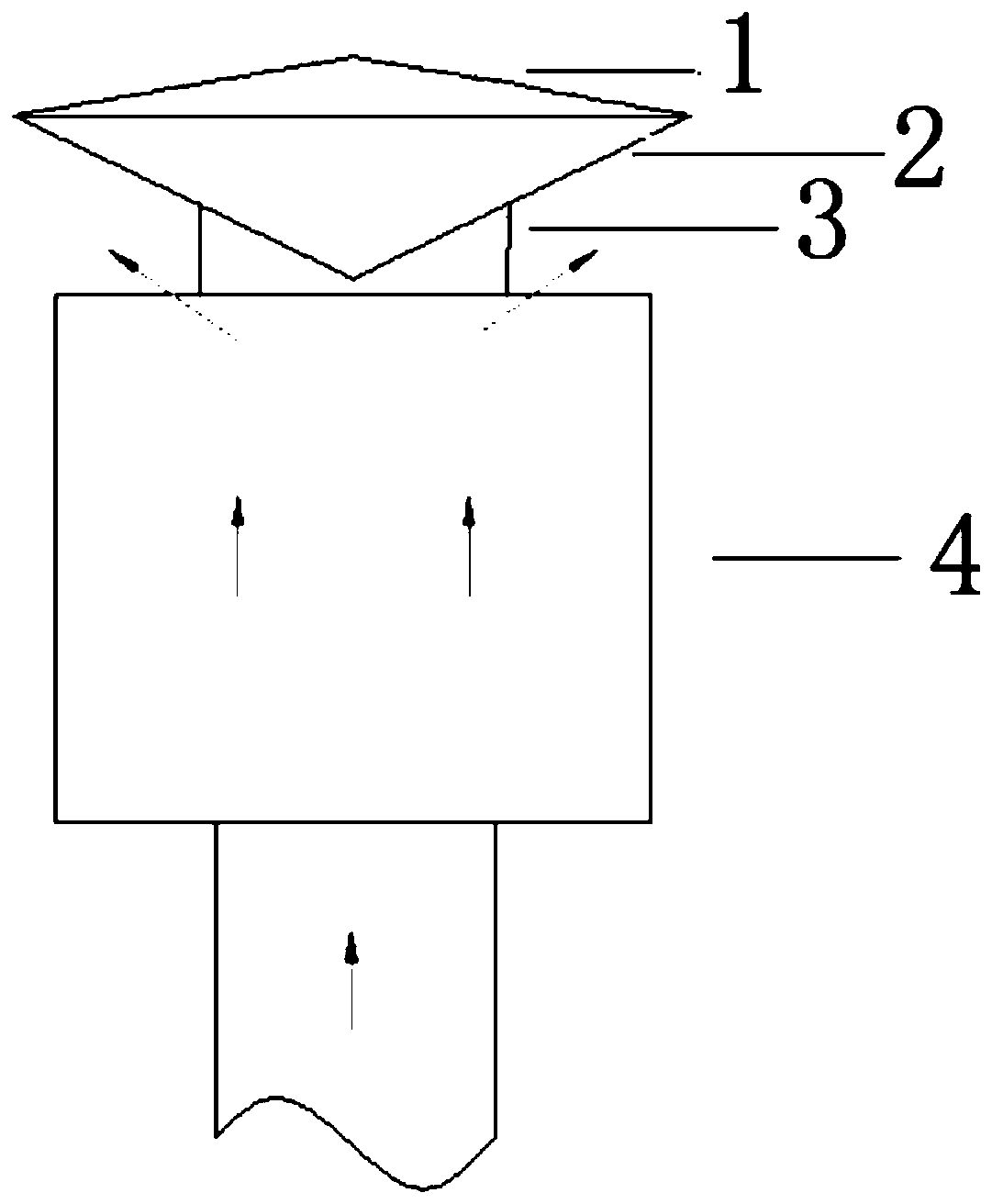

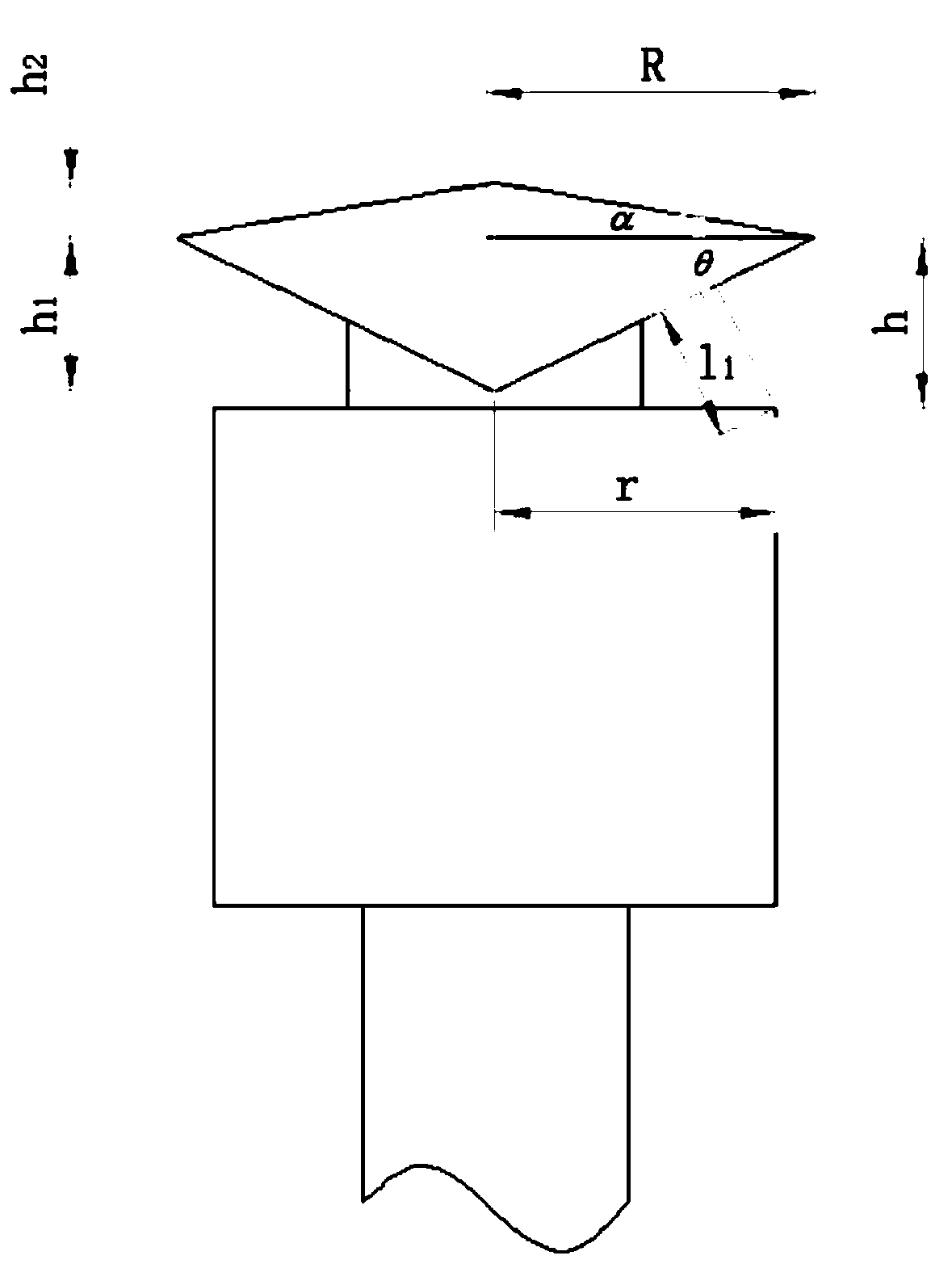

[0040] Comply with the above technical solutions, such as Figure 1-5 As shown, this embodiment provides an industrial gas compressor venting shield including a protective cover 1 , a guide body 2 , and a connecting rod 3 . Among them, the protective cover 1 is located at the top to prevent rain, snow, dust, etc. from entering the inside of the air supply duct, and is evenly discharged downward along the edge; the guide body 2 is located under the protective cover 1, and guides the air supply duct from the bottom to the upward airflow, It has small resistance, small friction and low noise.

[0041] As an embodiment, the air release shield of the industrial gas compressor of the present invention includes a cone shield, a diversion cone and a connecting rod, and is suitable for the outlet of the air discharge pipe to be a round pipe.

[0042] Specifically, the cone protective cover is rolled and welded by fan-shaped iron plates; the diversion cone is also rolled and welded by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com