Downhole power screw drilling tool

A screw drilling tool and power technology, which is applied to the driving device for drilling in the borehole, earthwork drilling, drilling equipment, etc., can solve the problems of low temperature resistance of the stator rubber and reduce the temperature of the stator rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

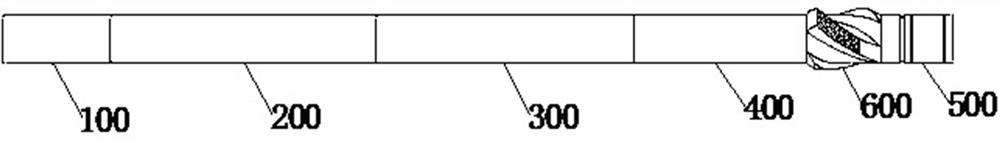

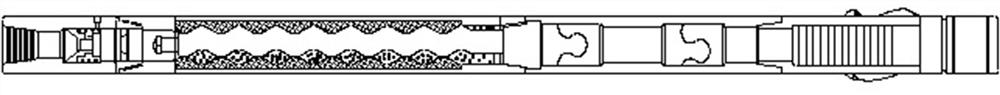

[0032] Such as figure 1 , 2 A downhole power screw drilling tool shown is composed of a bypass valve assembly 100 , a motor assembly 200 , a cardan shaft assembly 300 , a transmission shaft assembly 400 , a bit joint 500 and a stabilizer sleeve 600 . In this scheme, the valve assembly 1 million cardan shaft assembly 300, transmission shaft assembly 400, and drill joint 500 all adopt the existing technology, so this embodiment does not describe the above parts in detail, and any reasonable structural design can be used in the present invention.

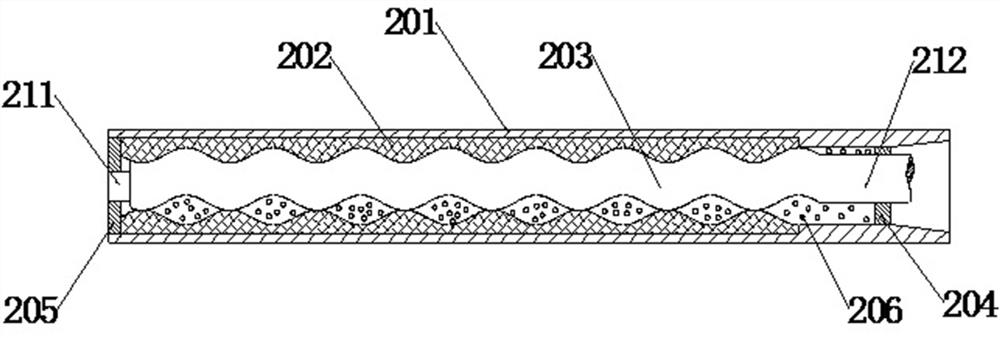

[0033] Such as image 3 As shown, the biggest improvement of this solution lies in the regulation of the motor assembly 200, thereby reducing its operating temperature. The motor assembly 200 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com