Composite material connecting sleeper beam for rail transit vehicle and forming method thereof

A technology for rail transit vehicles and composite materials, which is applied in the field of composite material bolsters and their forming for rail transit vehicles, can solve problems such as stress concentration, reduce wall thickness, improve the ability to withstand internal pressure, and reduce manufacturing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

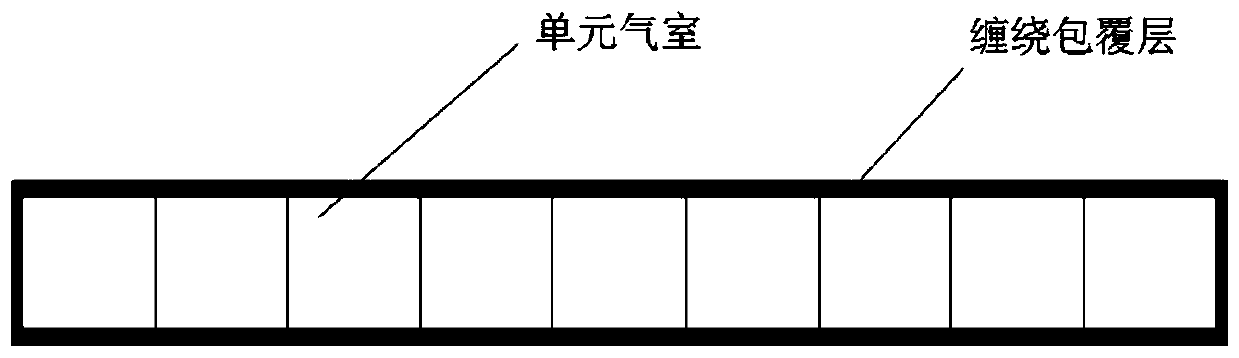

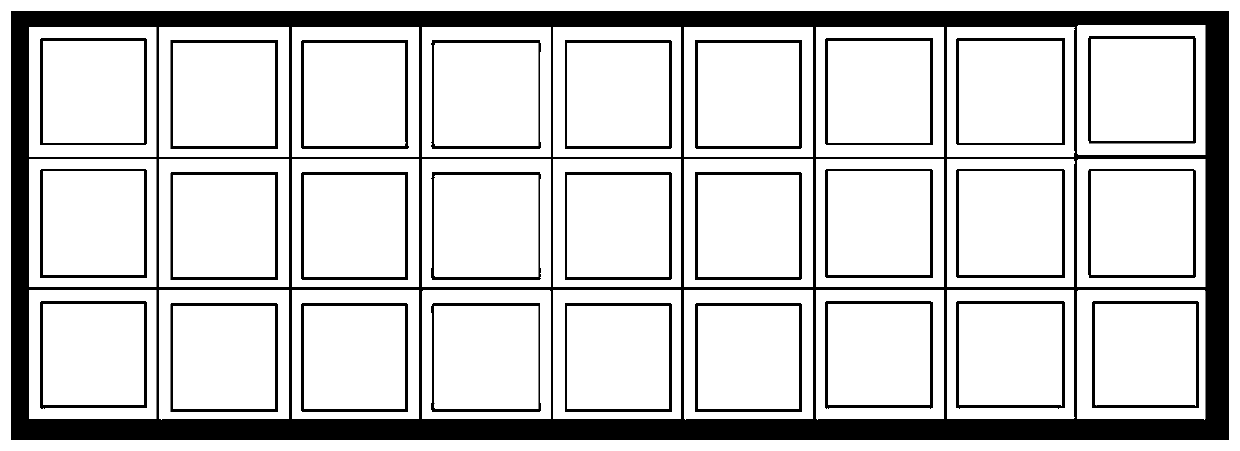

[0085] A composite material connecting corbel for a rail transit vehicle, the connecting corbel includes an upper wall plate, a lower wall plate and an air chamber, the air chamber includes a main structure and a cladding layer composed of 27 structural units arranged, the main structure is three layers, Such as Figure 1-3 As shown, the cladding layer is wound outside the main structure, and the air chamber is located between the upper wall plate and the lower wall plate; the structural unit is a prism with a top through hole, a bottom end through hole and a middle through hole (unit air chamber) , the inner diameter of the top through hole of the prism (unit air chamber) is smaller than the middle through hole, the inner diameter of the bottom through hole of the prism (unit air chamber) is smaller than the middle through hole, and the inner diameter of the top through hole of the prism (unit air chamber) is less than that of the prism The inner diameter of the bottom throug...

Embodiment 2

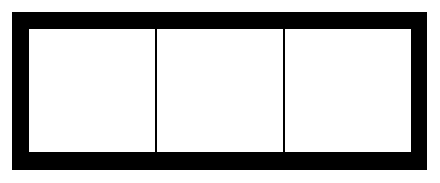

[0108] A composite material connecting corbel for a rail transit vehicle, the connecting corbel includes an upper wall plate, a lower wall plate and an air chamber, the air chamber includes a main structure composed of 30 structural units and a cladding layer, and the cladding layer is wound on the Outside the main structure, the air chamber is located between the upper wall plate and the lower wall plate; the structural unit is a prism (unit air chamber) with a top through hole, a bottom end through hole and a middle through hole, and the top of the prism (unit air chamber) The inner diameter of the through hole is less than the middle through hole, the inner diameter of the bottom through hole of the prism (unit air chamber) is smaller than the middle through hole, and the inner diameter of the top through hole of the prism (unit air chamber) is the same as the inner diameter of the bottom through hole of the prism;

[0109] Adjacent structural units are bonded by epoxy adhes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com