Manufacturing process of IMD type automobile rolling door

A manufacturing process and rolling door technology, which is applied to vehicle parts, household components, applications, etc., can solve the problems of increased patterns and manufacturing lines, soft glue that cannot achieve high-gloss effects, and soft glue that falls off, etc., to increase diversification , high gloss surface, low shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

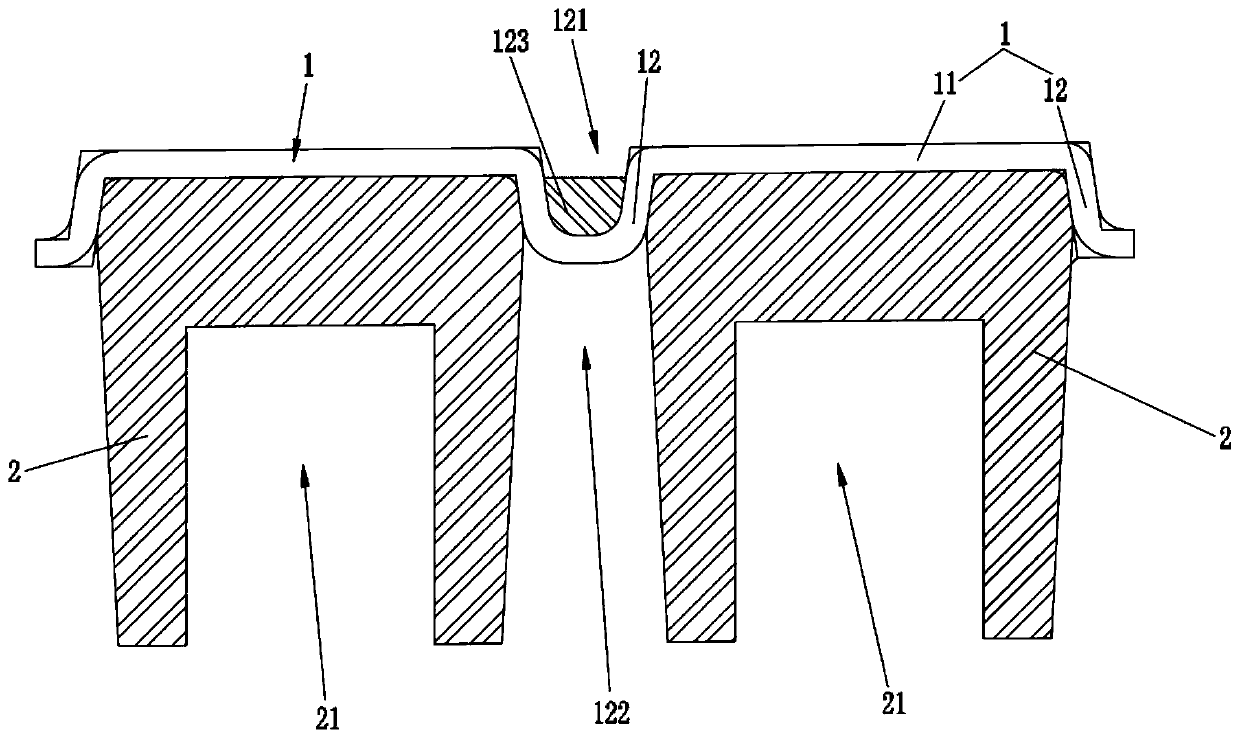

[0051] Embodiment two: if Figure 4 As shown, in this embodiment, the third groove 122 is provided with a second soft rubber layer 124, and the second soft rubber layer 124 is respectively connected to the connecting bending portion 12 and the hard rubber of two adjacent curtain units. 2. The second soft rubber layer 124 increases the connection strength of the connecting bent parts 12 of two adjacent curtain units, so that the connecting bent parts 12 of two adjacent curtain units can be firmly connected together, so that The adhesive film 1 is not easy to bend and break during being pulled, so that the adhesive film 1 can work normally.

Embodiment 3

[0052] Embodiment three: as Figure 5 As shown, in this embodiment, a fourth groove 125 is laser engraved on the connecting bending portion 12 of two adjacent curtain units, and the second soft rubber layer 124 is respectively connected to two adjacent curtain strips. The connection bending part 12 of the unit and the hard glue 2, at the same time, part of the second soft glue layer 124 protrudes into the fourth groove 125, and the second soft glue layer 124 increases the connection and bending of two adjacent curtain units The connection strength of the part 12 allows the connecting and bending parts 12 of two adjacent curtain units to be firmly connected together, so that the adhesive film 1 is not easy to bend and break during the pulling process, ensuring that the adhesive film 1 can be normal Work.

Embodiment 4

[0053] Embodiment four: as Figure 6 As shown, in this embodiment, the second groove 121 is provided with a first soft rubber layer 123, and the first soft rubber layer 123 is respectively connected to the connecting bending portions 12 of two adjacent curtain strip units. The third groove 122 is provided with a second soft rubber layer 124, and the second soft rubber layer 124 is respectively connected to the connecting bending portion 12 and the hard rubber 2 of two adjacent curtain units. The first soft rubber layer 123 and the second soft rubber layer 124 increase the connection strength of the connection bending part 12 of two adjacent curtain strip units, so that the connection bending part 12 of two adjacent curtain strip units can be tightened. are firmly connected together, so that the adhesive film 1 is not easy to bend and break during being pulled, and ensures that the adhesive film 1 can work normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com