A multi-wire cutting machine table feeding method based on stepless speed change

A multi-wire cutting machine, infinitely variable speed technology, applied in the direction of fine working devices, working accessories, manufacturing tools, etc., can solve the problems of reducing the flatness of cutting products, poor accuracy, uneven thickness of the cutting surface, etc. The parameters are stable, the accuracy is good, and the effect of improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

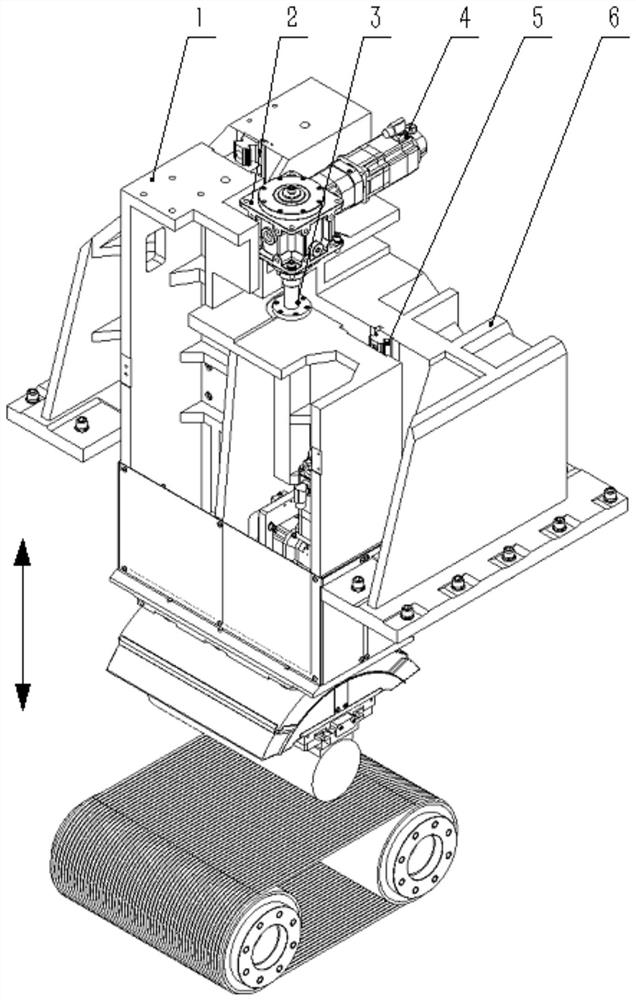

[0029] Such as figure 1 As shown, the circular material is fixed on the workbench sliding seat 1, and the workbench sliding seat 1 is connected and fixed on the workbench fixing seat 6 by the linear slide rail 5. The programmable controller controls the servo motor 4 to drive the reducer 2, and the screw rod 3 is connected with the reducer 2, the screw rod 3 drives the sliding seat 1 of the workbench to move up and down, and the servo motor 4 feeds back the real-time position of the workbench to the programmable controller.

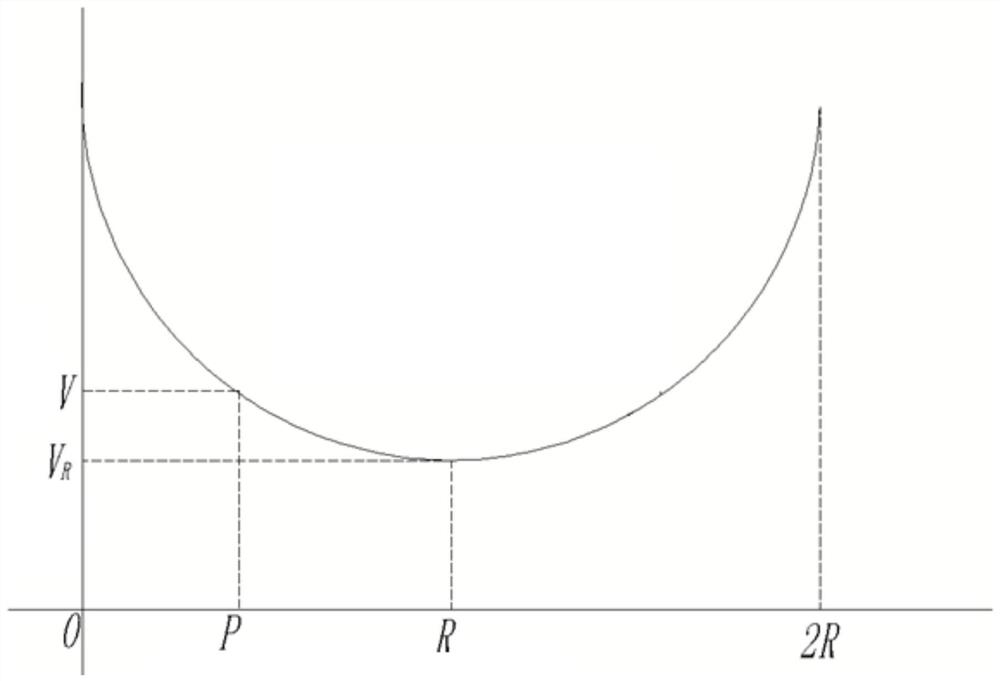

[0030] A multi-wire cutting machine worktable feeding method based on stepless speed change is: the real-time feed speed of the workbench is stepless speed change, and the speed is the same at the same contact area between the cutting line and the circular material;

[0031] The specific steps are:

[0032] Drive the table feed through a set of servo motors and feed back the relative displacement according to the servo motor encoder data P , the relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com