Automatic mechanical clamping jaw and robot

A technology of mechanical grippers and grippers, applied in the field of mechanical grippers, can solve the problems of reducing the automation degree of robots, single application occasions, poor controllability, etc., and achieve the effects of high automation, wide application occasions, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

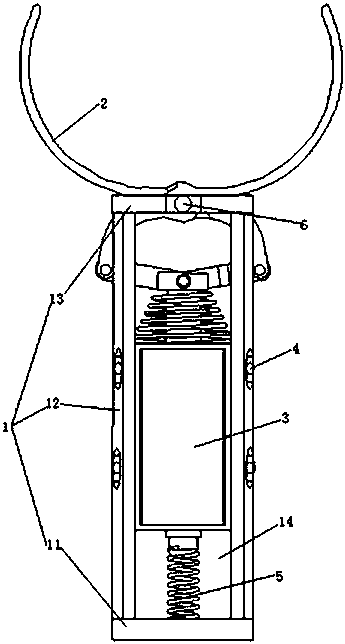

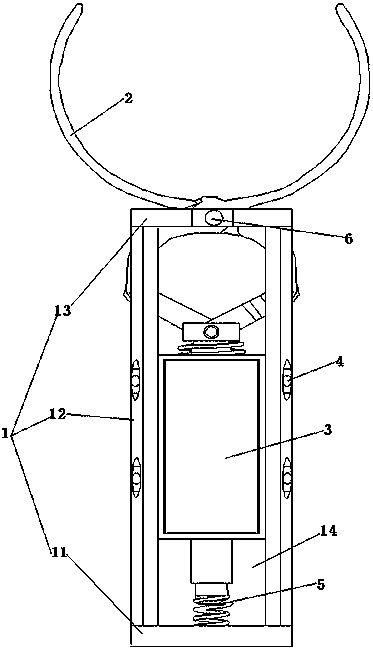

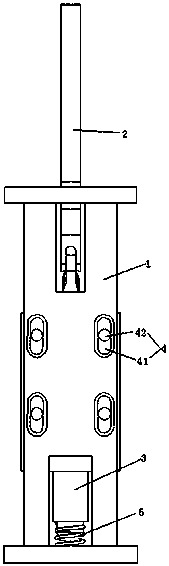

Examples

Embodiment 2

[0058] In this specific embodiment, the automatic mechanical gripper of the present invention is basically the same as that of Embodiment 1, except that the coil body 31 and the first elastic member 33 are replaced by hydraulic cylinders, pneumatic cylinders or electric cylinders.

[0059]When clamping different objects, the first jaw 21, the second jaw 22, the first push-pull link 23 and the second push-pull link 24 form a linkage mechanism. The coil body 31 moves up and down relative to the support assembly 1, and after being adjusted to a suitable position, fix both sides of the hydraulic cylinder or pneumatic cylinder or electric cylinder on the side wall of the support assembly 1 with fasteners 42; then, the hydraulic cylinder Or the pneumatic cylinder or electric cylinder drives the push-pull rod 32 to move downward, driving the first push-pull connecting rod 23 and the second push-pull connecting rod 24 to move downward, the first jaw 21 and the second jaw 22 can rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com