Shot blasting device for complex cavity in casting

A shot blasting device and cavity technology, which is applied in the abrasive feeding device, the used abrasive processing device, the explosion generating device, etc., to achieve the effects of increasing shot blasting energy, avoiding wear damage, and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

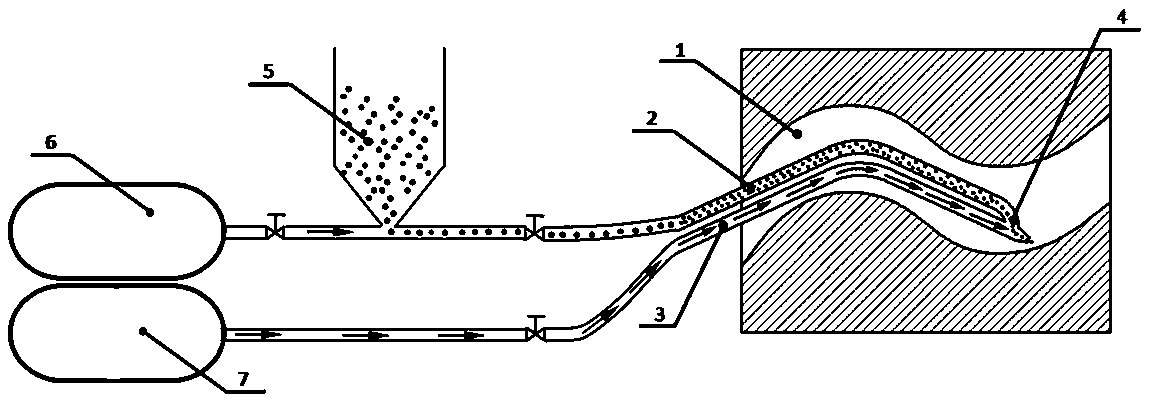

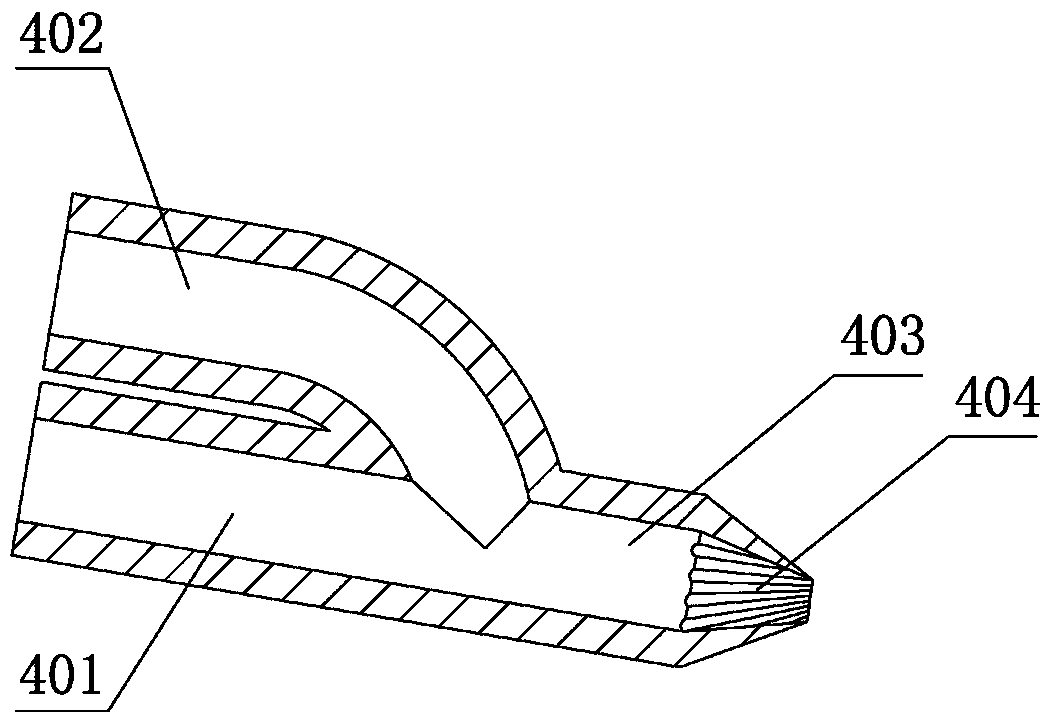

[0019] Such as figure 1 and figure 2 The shot blasting device of the complex cavity inside the casting shown in the present invention includes a low-pressure feeding pipeline 2, a high-pressure power pipeline 3 and a Y-shaped shot blasting joint 4, and the Y-shaped shot blasting joint 4 is provided with a shot blasting medium feed port 402 , high-pressure air inlet 401 and shot blasting outlet 403, low-pressure feed pipeline 2 is connected with shot blasting medium feed inlet 402, high-pressure power pipeline 3 is connected with high-pressure air inlet 401, low-pressure feed pipeline 2 and high-pressure power pipeline 3 In order to facilitate the conformal hose extending into the inner cavity of the casting, wear-resistant rubber hose or metal hose can be used, and the Y-shaped shot blasting joint 4 is made of wear-resistant metal materials, such as high manganese steel or martensitic steel. .

[0020] In order to facilitate the transportation of the shot blasting medium, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com