An automatic assembly adsorption device

An adsorption device and automatic assembly technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of upright warping, reverse warping or wave warping, assembly and attachment deviation, and inability to accurately position, so as to achieve assembly or Accurate attachment, satisfying assembly or attachment, and reducing material scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the drawings and specific embodiments, the present invention will be described in detail. Before describing the technical solutions of the various embodiments of the present invention in detail, the terms and terms involved will be explained. In this specification, the same name or the same number Components represent similar or identical structures and are for illustrative purposes only.

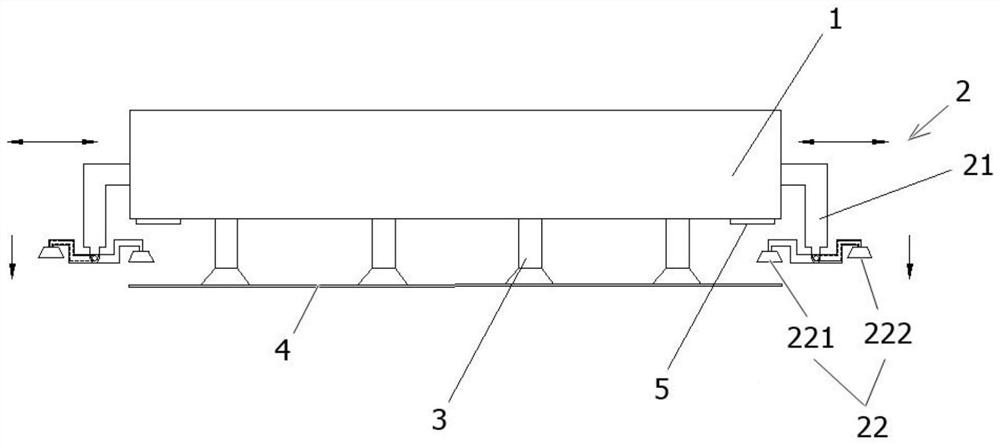

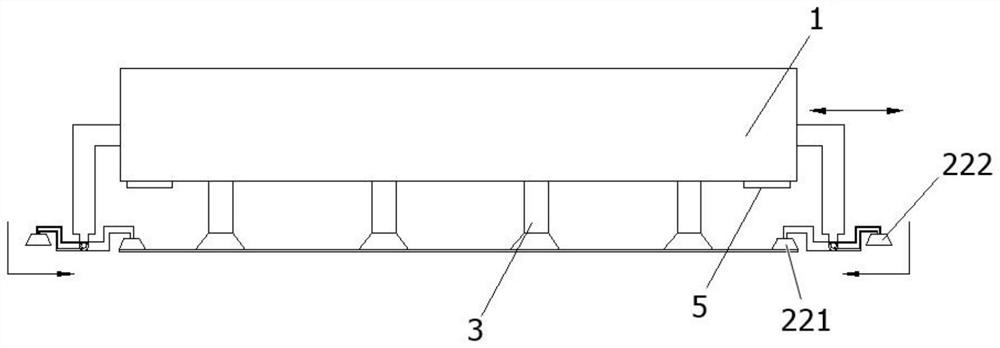

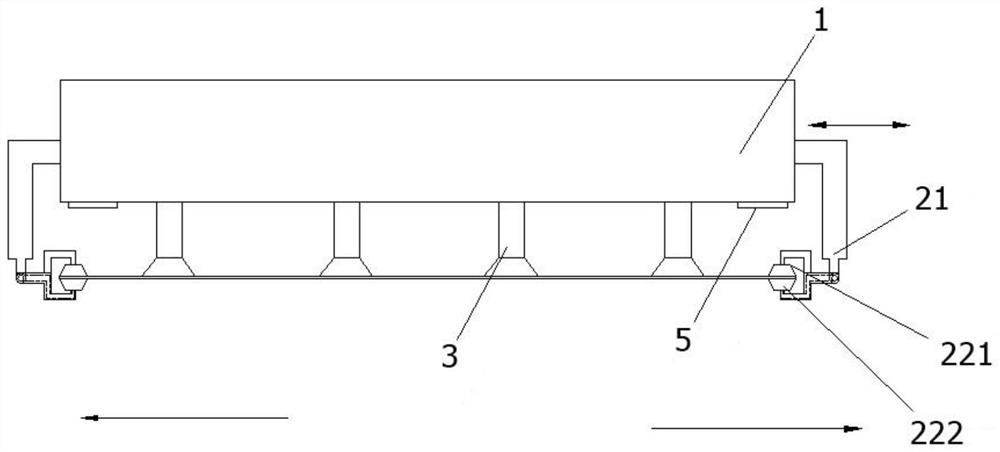

[0019] like figure 1 As shown, the automatic assembly adsorption device includes an adsorption plate 1 and an edge adsorption device 2, wherein the adsorption plate is a rectangular structure, and other planar structures can also be used, and several suction nozzles 3 are vertically arranged on the surface, and each suction nozzle Interconnected and connected with an external or built-in high-pressure gas device. The suction nozzles on the adsorption plate are used to absorb the sheet body, and the number is designed according to the size of the sheet.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com