Dual-wavelength pumped erbium-doped fluoride fiber laser and laser generating method

A fiber laser and pump laser technology, applied in the laser field, can solve the problems of long life, unfavorable inversion particle number, etc., and achieve the effect of increasing slope efficiency and output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

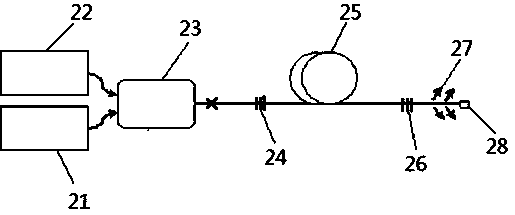

[0051] A dual-wavelength pumped erbium-doped fluoride fiber laser, the fiber laser comprising:

[0052] Such as figure 2 As shown, 976nm pump laser 21, 1.610μm pump laser 22, beam combiner 23, first fiber Bragg grating 24, double-clad erbium-doped fluoride fiber 25, second fiber Bragg grating 26, cladding mode stripper 27. AlF 3 end cap 28.

[0053] The first Fiber Bragg Grating 24 and AlF 3 The end cap 28 together constitutes the optical resonant cavity of the 2.8 μm band fiber laser, and the laser light with a wavelength of 2.825 μm is produced by AlF 3 End cap 28 output.

[0054] The output wavelength of the pump laser 21 is 976nm, and the output wavelength of the pump laser 22 is 1610nm. After the two laser beams are combined by the beam combiner 23, they are respectively coupled into the inner cladding and core of the double-clad erbium-doped fluoride optical fiber 25. middle.

[0055] The inner cladding diameter of the double-clad erbium-doped fluoride optical fib...

Embodiment 2

[0061] A dual-wavelength pumped erbium-doped fluoride fiber laser, the fiber laser comprising:

[0062] Such as figure 2 As shown, 976nm pump laser 21, 1.613μm pump laser 22, beam combiner 23, first fiber Bragg grating 24, erbium-doped fluoride fiber 25, second fiber Bragg grating 26, cladding mode stripper 27, AlF 3 end cap 28.

[0063] The first Fiber Bragg Grating 24 and AlF 3 The end cap 28 together constitutes the optical resonant cavity of the 2.8 μm band fiber laser, and the laser light with a wavelength of 2.825 μm is produced by AlF 3 End cap 28 output.

[0064] The output wavelength of the pump laser 21 is 976 nm, and the output wavelength of the pump laser 22 is 1613 nm. The two laser beams are combined by the beam combiner 23 and then coupled into the double-clad erbium-doped fluoride fiber 25 .

[0065] The diameter of the inner cladding of the double-clad erbium-doped fluoride optical fiber 25 is 200 μm, and the diameter of the core of the double-clad erbium...

Embodiment 3

[0071] A dual-wavelength pumped erbium-doped fluoride fiber laser, the fiber laser comprising:

[0072] Such as figure 2 As shown, 976nm pump laser 21, 1.617μm pump laser 22, beam combiner 23, first fiber Bragg grating 24, erbium-doped fluoride fiber 25, second fiber Bragg grating 26, cladding mode stripper 27, AlF 3 end cap 28.

[0073] The first Fiber Bragg Grating 24 and AlF 3 The end caps 28 together constitute the optical resonant cavity of the 2.8 μm band fiber laser, and the generated 2.825 μm band laser is produced by AlF 3 End cap 28 output.

[0074] The output wavelength of the pump laser 21 is 976 nm, and the output wavelength of the pump laser 22 is 1617 nm. After the two laser beams are combined by the beam combiner 23, they are respectively coupled into the inner cladding of the double-clad erbium-doped fluoride optical fiber 25 and in the fiber core.

[0075] The inner cladding diameter of the double-clad erbium-doped fluoride optical fiber 25 is 250 μm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Core diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com