Micro driver based on surface plasmon polariton waveguide structure

A surface plasmon and waveguide structure technology, applied in the direction of microstructure devices composed of deformable elements, microstructure technology, microstructure devices, etc., can solve the problems of lack of independence, high temperature rise of the driving arm, and difficult overall structure Miniaturization and other issues to achieve the effect of multiple control, high energy density, good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

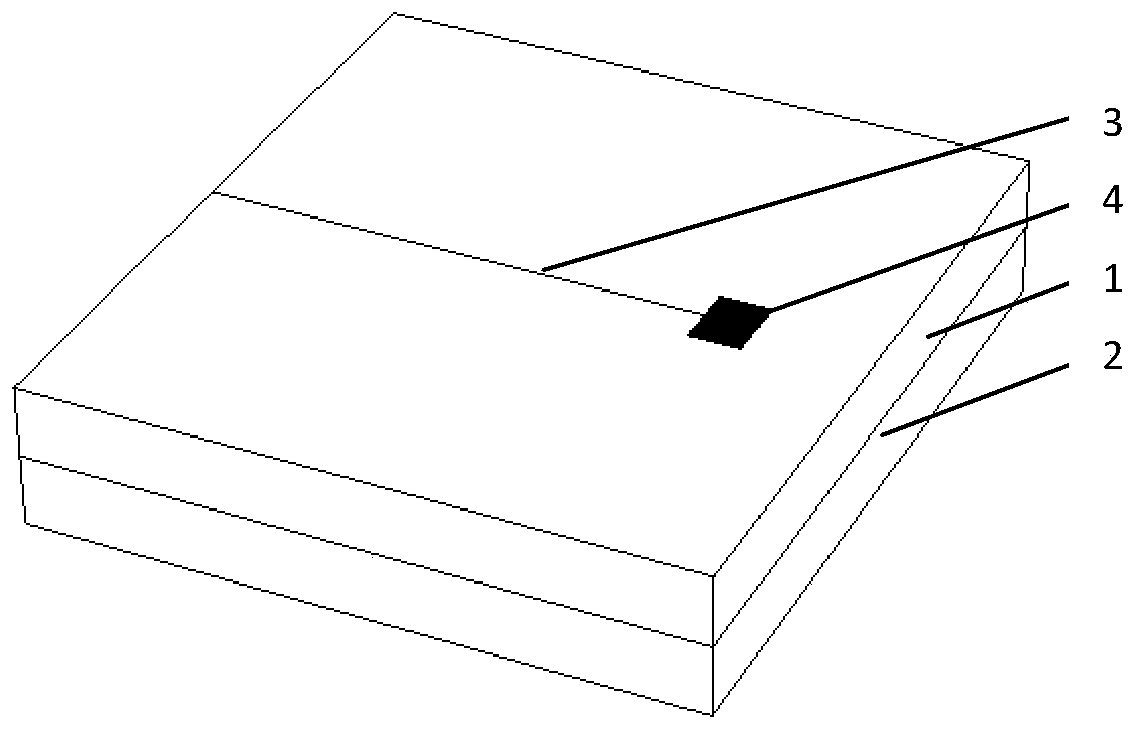

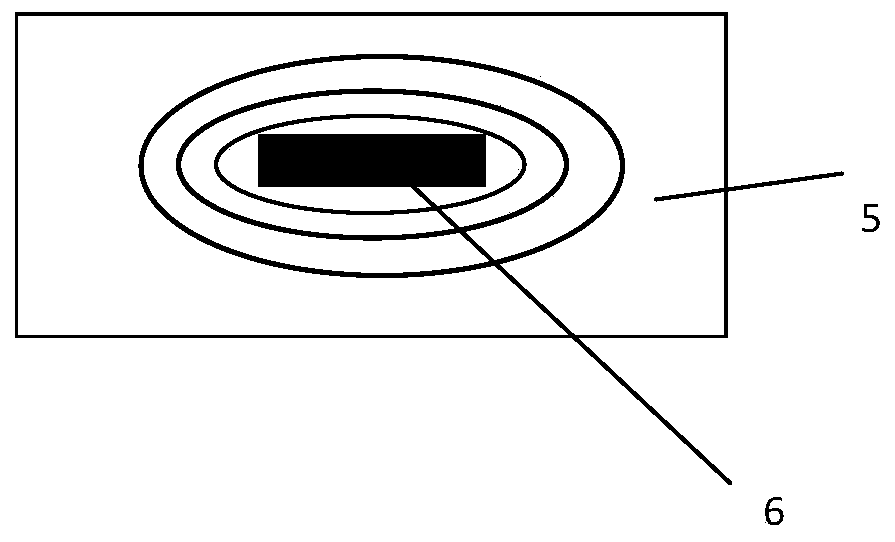

[0036] This embodiment provides a curved micro-actuator based on a surface plasmon waveguide structure, the structure of which is as follows Image 6 and Figure 7 As shown, it includes a two-layer laminated surface plasmon waveguide layer 1 and a driving arm layer 2 . A surface plasmon waveguide structure 3 and a light-to-heat conversion region 4 are arranged on the surface plasmon waveguide layer 1. By introducing optical signals, electrical signals or photoelectric multiplexing signals into the surface plasmon waveguide structure 3 for transmission, the transmission mode of the incident signal is limited by the surface plasmon waveguide structure 3, so that the input photoelectric signal is transmitted to the photothermal The conversion region 4 generates a thermal effect to realize the action of the driving arm layer 2 .

[0037]The surface plasmon waveguide layer 1 can be a single layer or multiple layers, and the light-to-heat conversion region 4 can be located in the ...

Embodiment 2

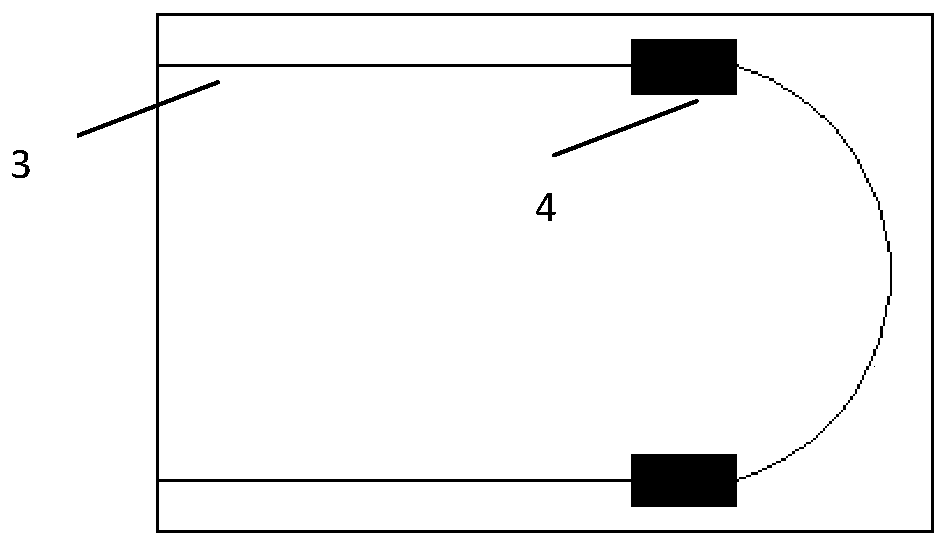

[0040] This embodiment provides an "S" curved micro-actuator based on a surface plasmon waveguide structure, the structure of which is as follows Figure 8 As shown, it includes two surface plasmon waveguide layers 1 stacked in sequence, a top waveguide layer 11 and a bottom waveguide layer 12 . Wherein the top waveguide layer 11 and the bottom waveguide layer 12 are provided with a surface plasmon waveguide structure 3 , a top layer light-to-heat conversion region 41 and a bottom layer light-to-heat conversion region 42 . By introducing optical signals, electrical signals or photoelectric multiplexing signals into the surface plasmon waveguide structure 3 for transmission, the transmission mode of the incident signal is limited by the surface plasmon waveguide structure 3, so that the input photoelectric signal is transmitted to the top layer of light The heat conversion region 41 and the bottom light-to-heat conversion region 42 generate a thermal effect to realize the actio...

Embodiment 3

[0044] This embodiment provides a continuously curved surface plasmon waveguide structure micro-driver, the structure of which is as follows Figure 9 As shown, it includes a top waveguide layer 11 , a driving arm layer 2 and a bottom waveguide layer 12 stacked in sequence. Wherein the top waveguide layer 11 and the bottom waveguide layer 12 are respectively provided with a surface plasmon waveguide structure 3 and a top light-to-heat conversion region 41 and a bottom light-to-heat conversion region 42 .

[0045] By introducing optical signals, electrical signals or photoelectric multiplexing signals into the surface plasmon waveguide structure 3 for transmission, the transmission mode of the incident signal is limited by the surface plasmon waveguide structure 3, so that the input photoelectric signal is transmitted to the top layer of light The heat conversion region 41 and the bottom light-to-heat conversion region 42 generate a thermal effect to realize the action of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com