Nondestructive detection method for improving void detection precision of CRTS III-type track slab

A technology for non-destructive testing and testing accuracy, which is applied to measuring devices, railway vehicle shape measuring devices, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. It can solve the problem that energy extremes cannot fully reflect repeatable test results, differences, peak Obvious problems, etc., to achieve the effect of reliable comparison results, strong reference, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A non-destructive testing method for improving the detection accuracy of CRTS III type track slab void detection, comprising the following steps:

[0039] (a) Arrange several measuring points on the track slab, and knock the whole track slab point by point along the measuring points;

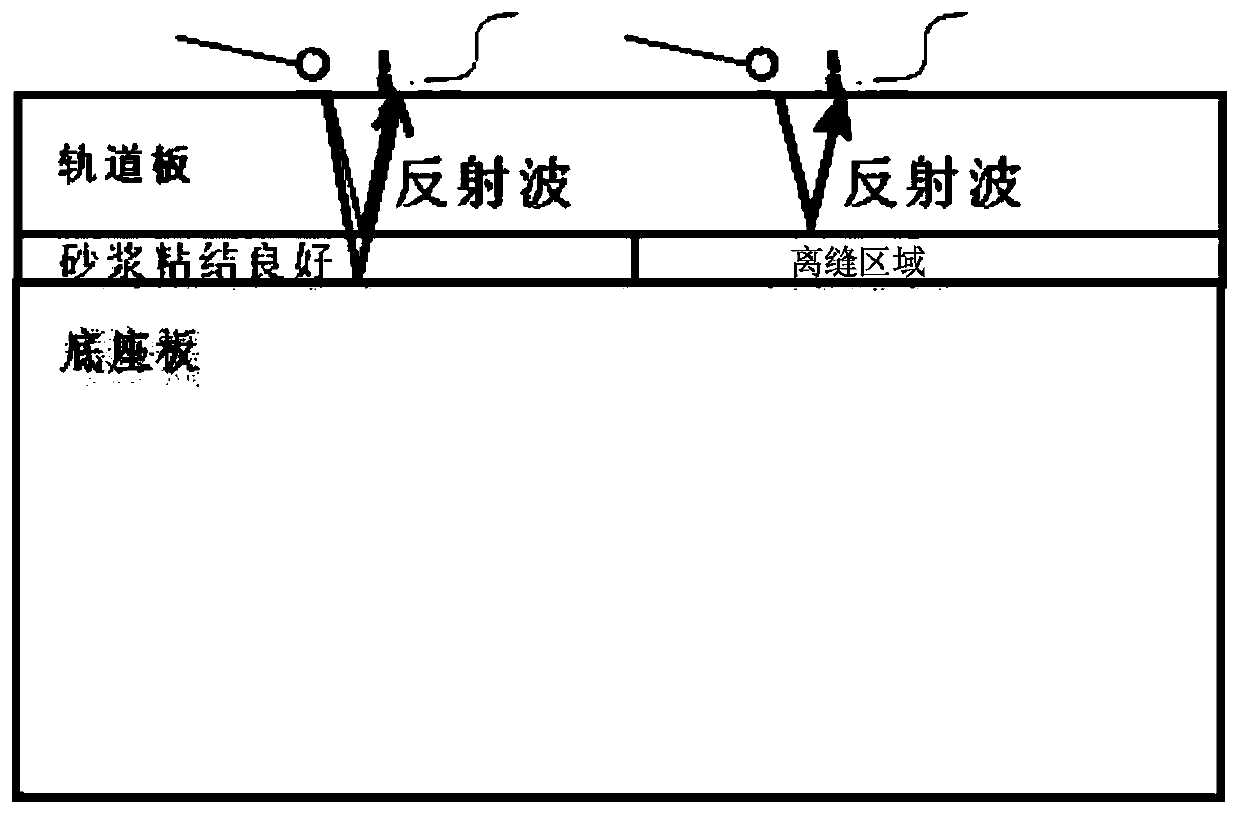

[0040] (b) receiving the shock elastic wave signal generated after hitting the track plate;

[0041] (c) Perform sequence transformation and frequency spectrum analysis to extract the reflected signal from the bottom surface of the track slab and the reflected signal from the bottom surface of the self-compacting concrete;

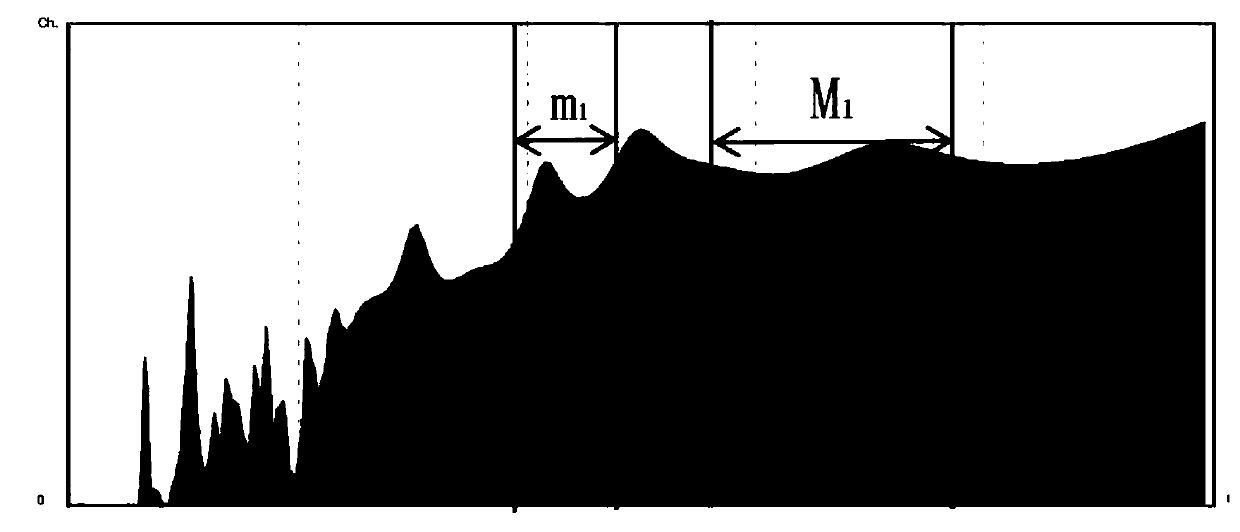

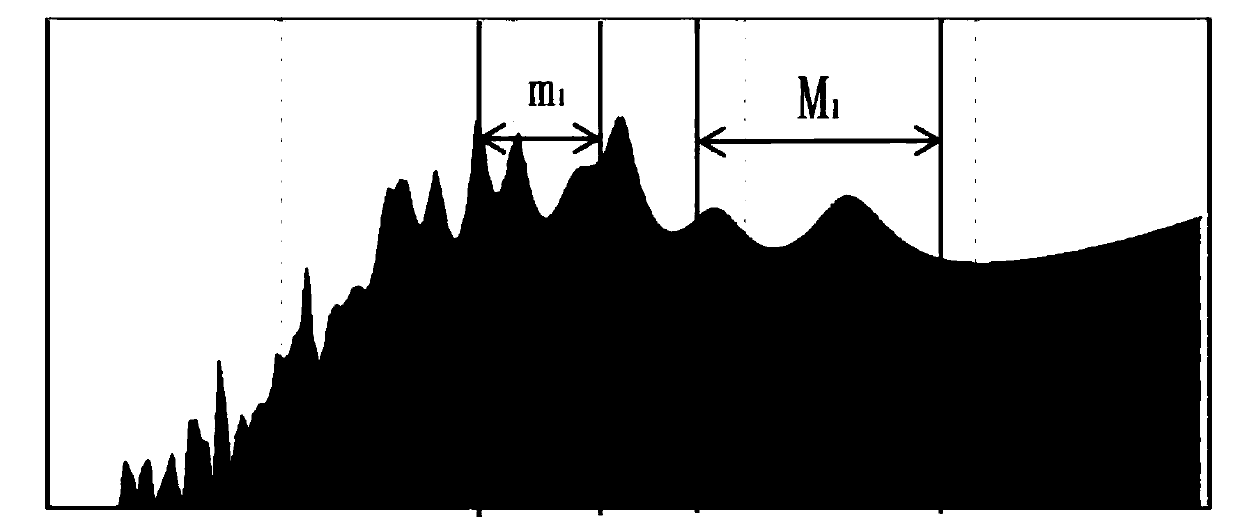

[0042] (d) According to the ratio of the average reflected energy of the bottom surface of the track slab and the average reflected energy of the self-compacting concrete bottom surface, the degree of voiding is judged.

[0043] The peak value of the traditional detection method is not obvious after the reflection energy is averaged, and the repeatability test result...

Embodiment 2

[0046] Include the following steps.

[0047] 1. Determine the state of the tested CRTS III track slab (including: size, whether the surface is dry, etc.);

[0048] 2. Use the signal excitation device to stimulate the signal, so that the signal propagates inside the CRTS III track plate under test;

[0049] 3. Use the signal receiving device to receive the signal that has propagated inside the CRTS III track slab;

[0050] 4. Tap the entire CRTS III track plate point by point along the measuring point;

[0051] 5. Use special analysis software to analyze the received signals, and set parameters such as sequence transformation, spectrum analysis, slice range, slice contour map, etc. for all the obtained signals;

[0052] 6. Spectrum analysis is set to use MEM (Maximum Entropy Method) for analysis, and the sampling interval is calculated at 0.001ms.

[0053] 7. By controlling the ratio of the average energy value reflected by the slice range, the void situation of the CRTS III...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com