Pressurizing device for rapidly plugging cast oil lines

An oil circuit and fast technology, applied in the direction of measuring devices, applying stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems such as the inability to arrange the plugging cover, the inability to use the machine method, and the long plugging operation time, etc. Achieve plugging effect and good versatility, great practical application value, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

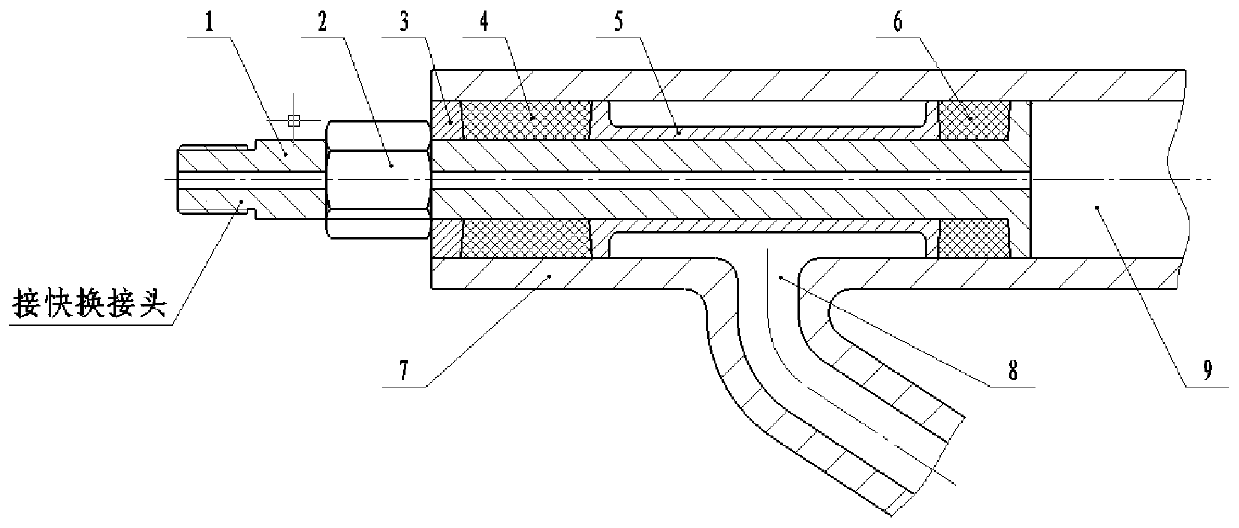

[0017] see figure 1 , The tensioning and blocking device in the oil passage of the present invention includes a locking rod, a locking nut, a compression ring, a sealing sleeve, a compression sleeve, and a sealing ring. Wherein, the center of the locking rod is provided with an air inlet, the right end is provided with a bottom plate, the sealing ring is sleeved on the bottom plate end of the locking rod, the right side of the sealing ring is attached to the bottom plate, and the inner diameter is attached to the outer diameter of the locking rod. The tight sleeve is connected to the locking rod, the right side of the compression sleeve is attached to the left side of the sealing ring, the sealing sleeve is sleeved on the locking rod, the right side of the sealing sleeve is attached to the left side of the compression sleeve, and the compression ring is sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com