Microporous trapezoidal polymer and synthesis method and application thereof

A polymer and trapezoidal technology, applied in the direction of organic compound/hydride/coordination complex catalysts, chemical instruments and methods, water treatment of special compounds, etc., can solve the problem that trapezoidal polymers do not have photosensitization, and achieve excellent Photosensitization properties, good processing performance, simple separation and purification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

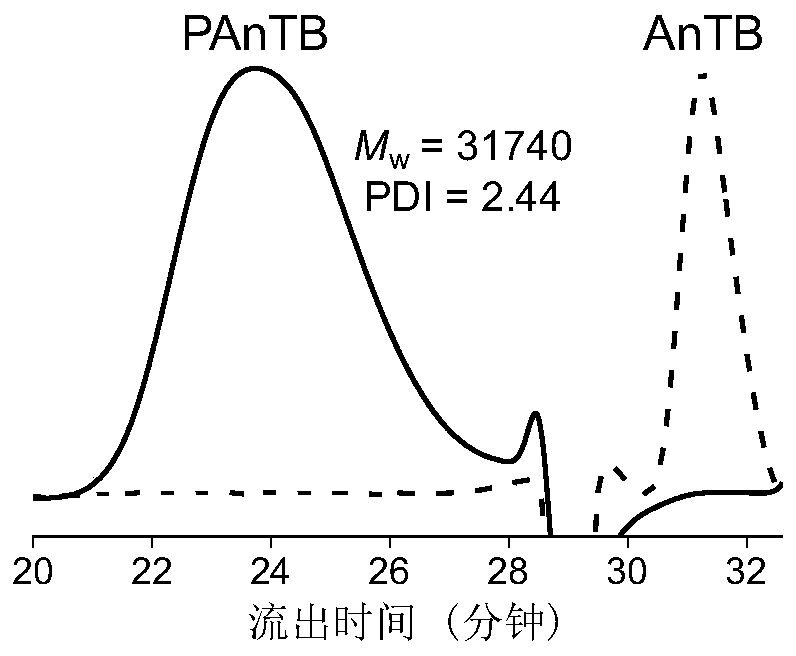

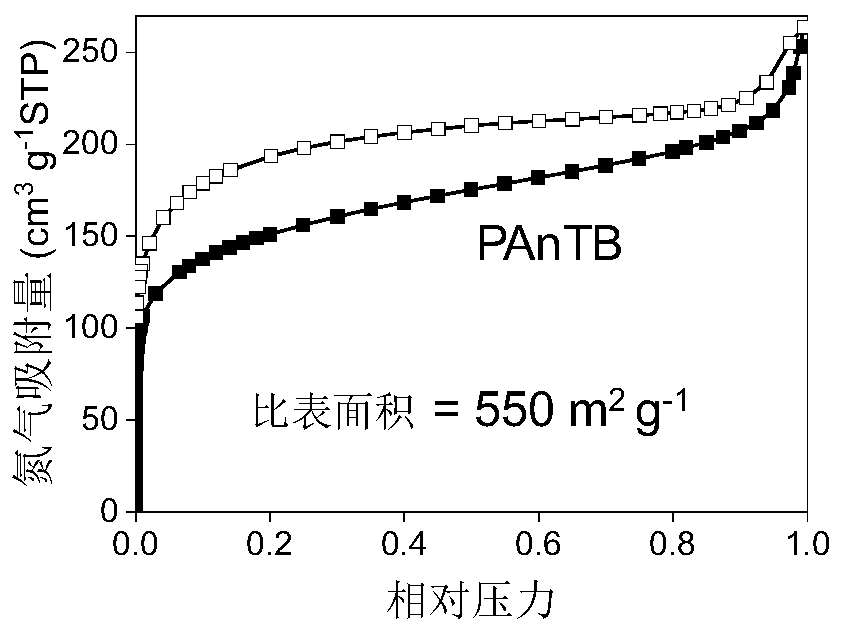

[0034] The preparation method of microporous ladder polymer (PAnTB) in the present invention comprises the following steps:

[0035] (1) Add bisanthracene monomer (AnTB) (50mg) into chlorobenzene (10mL) at a monomer concentration of (5mg / mL), stir well until completely dissolved. The synthetic method of double anthracene monomer (AnTB) is prior art, can refer to: (A.Tatar et al.Org.Lett.2010,12,1872; M.Havlik et al.Collect.Czech.Chem.Commun.2007, 72,392).

[0036] (2) The homogeneous solution prepared in step (1) is used to remove the residual oxygen in the system by a freeze-thaw method, and the system is filled with nitrogen. The freeze-thaw method refers to that after the homogeneous solution is frozen into a solid state by liquid nitrogen, the residual oxygen in the system is removed by vacuuming, and then melted in an environment filled with nitrogen, and the operation is repeated three times to completely remove the oxygen in the system.

[0037] (3) At a temperature o...

Embodiment 2

[0039] figure 1 It is the synthetic route of the microporous ladder polymer (PAnTB) of the present invention. The preparation method of microporous ladder polymer (PAnTB) in the present invention comprises the following steps:

[0040] (1) Add bisanthracene monomer (AnTB) (150mg) into chlorobenzene (10mL) at a monomer concentration of (15mg / mL), stir well until completely dissolved.

[0041] (2) The homogeneous solution prepared in step (1) is used to remove the residual oxygen in the system by a freeze-thaw method, and the system is filled with nitrogen.

[0042] (3) At a temperature of 20°C, irradiate the homogeneous solution prepared in step (2) with a 10W LED lamp with a wavelength of 365nm, stop the light after 7 hours of reaction, and remove the solvent by a rotary evaporator to obtain a microporous trapezoidal polymerization (PAnTB) with a yield of 96.4%.

Embodiment 3

[0044] figure 1 It is the synthetic route of the microporous ladder polymer (PAnTB) of the present invention. The preparation method of microporous ladder polymer (PAnTB) in the present invention comprises the following steps:

[0045] (1) Add bisanthracene monomer (AnTB) (50mg) into dimethyl sulfoxide (10mL) at a monomer concentration of (5mg / mL), stir well until completely dissolved.

[0046] (2) The homogeneous solution prepared in step (1) is used to remove the residual oxygen in the system by a freeze-thaw method, and the system is filled with nitrogen.

[0047](3) At a temperature of 20°C, irradiate the homogeneous solution prepared in step (2) with a 10W LED lamp with a wavelength of 365nm, stop the light after 7 hours of reaction, and remove the solvent by a rotary evaporator to obtain a microporous trapezoidal polymerization (PAnTB) with a yield of 98.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com