Automatic wire winding machine

An automatic winding machine and wire technology, which is applied in the transportation of filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of too long wires, unable to meet work requirements, and unable to manually set the length of wires, etc. Precisely pre-determined length of wire, the effect of precise winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present application will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following exemplary embodiments and descriptions are only used to explain the present invention, not as a limitation to the present invention, and, in the case of no conflict, the embodiments in the application and the features in the embodiments can be combined with each other .

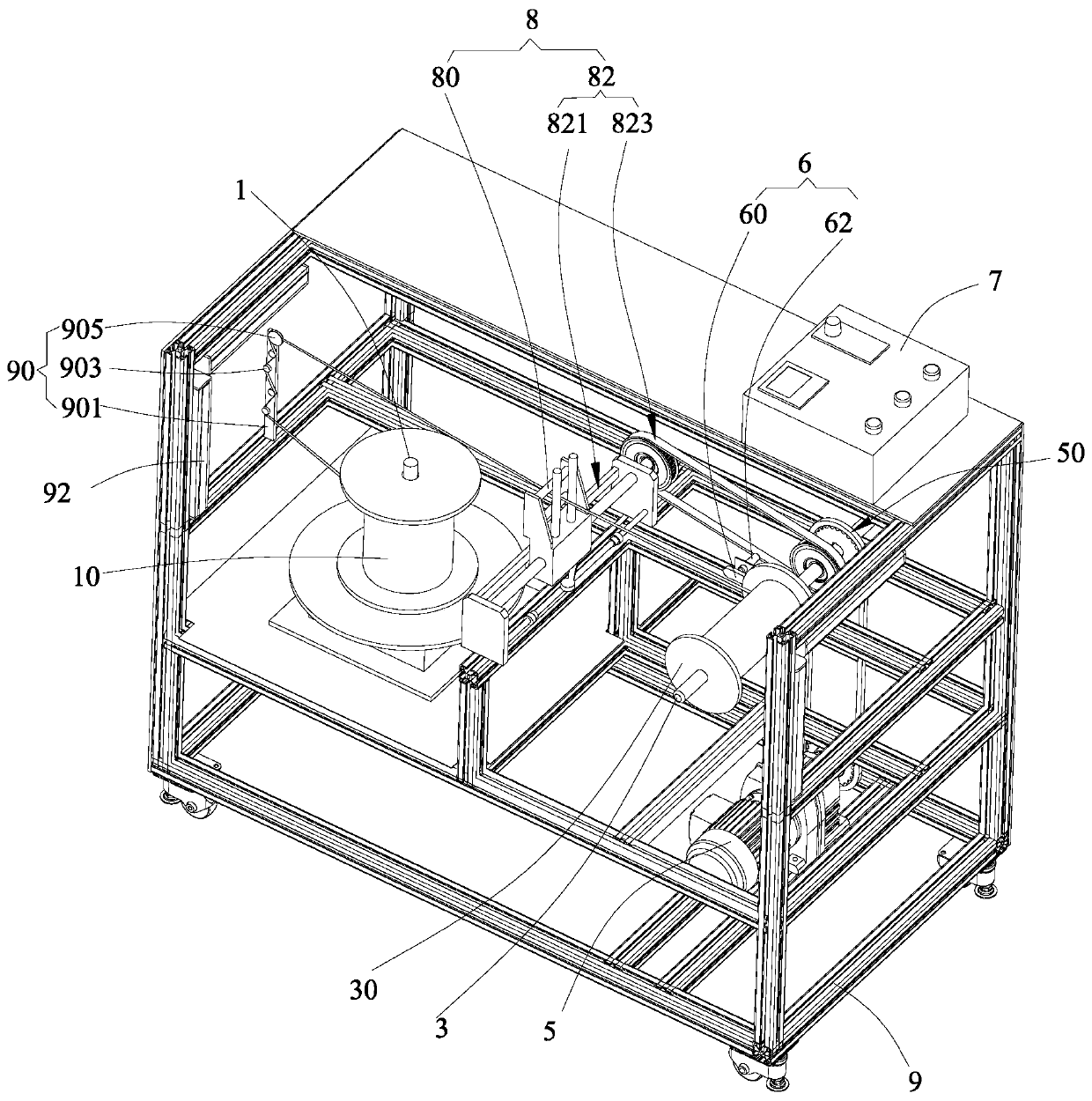

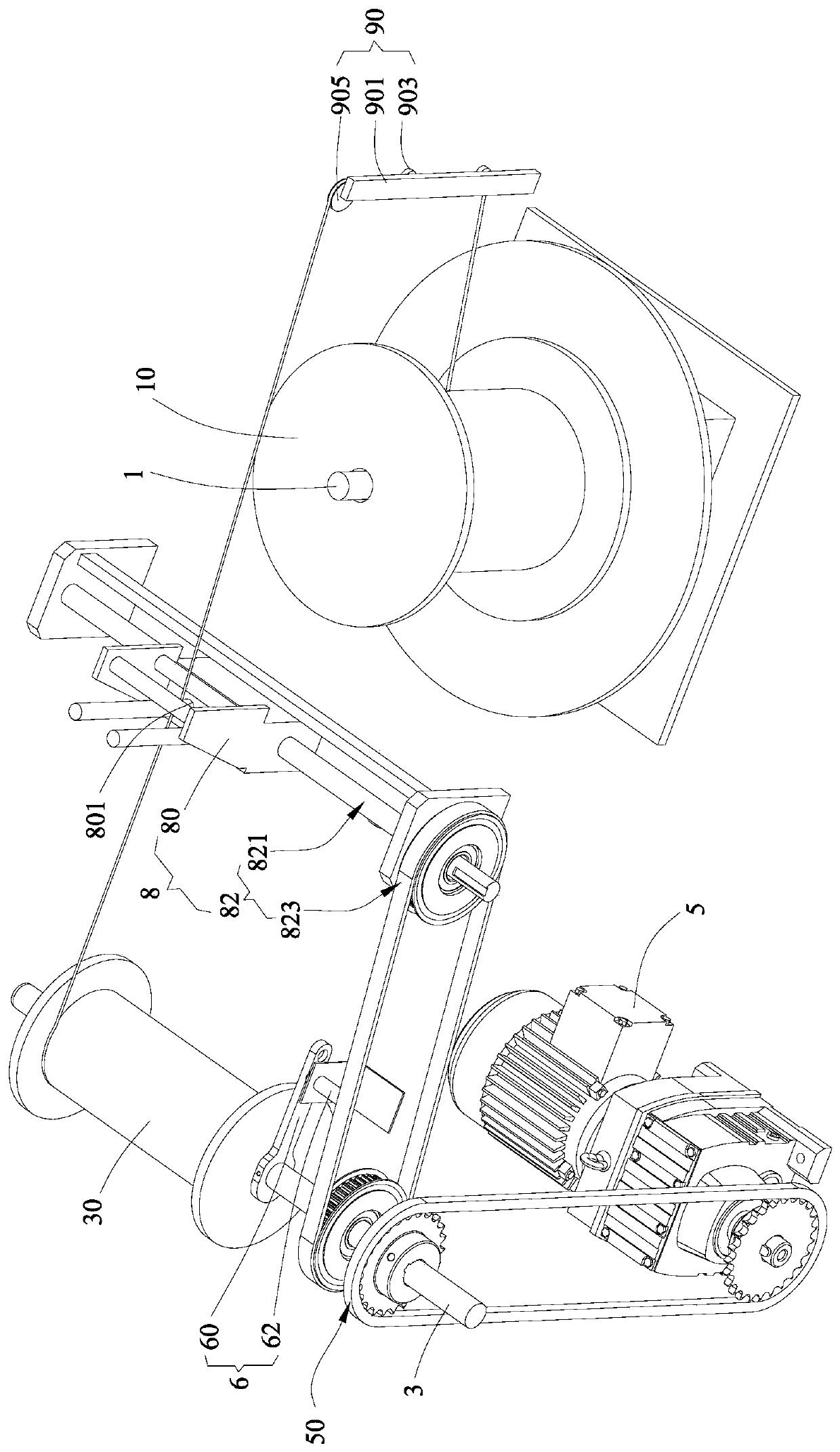

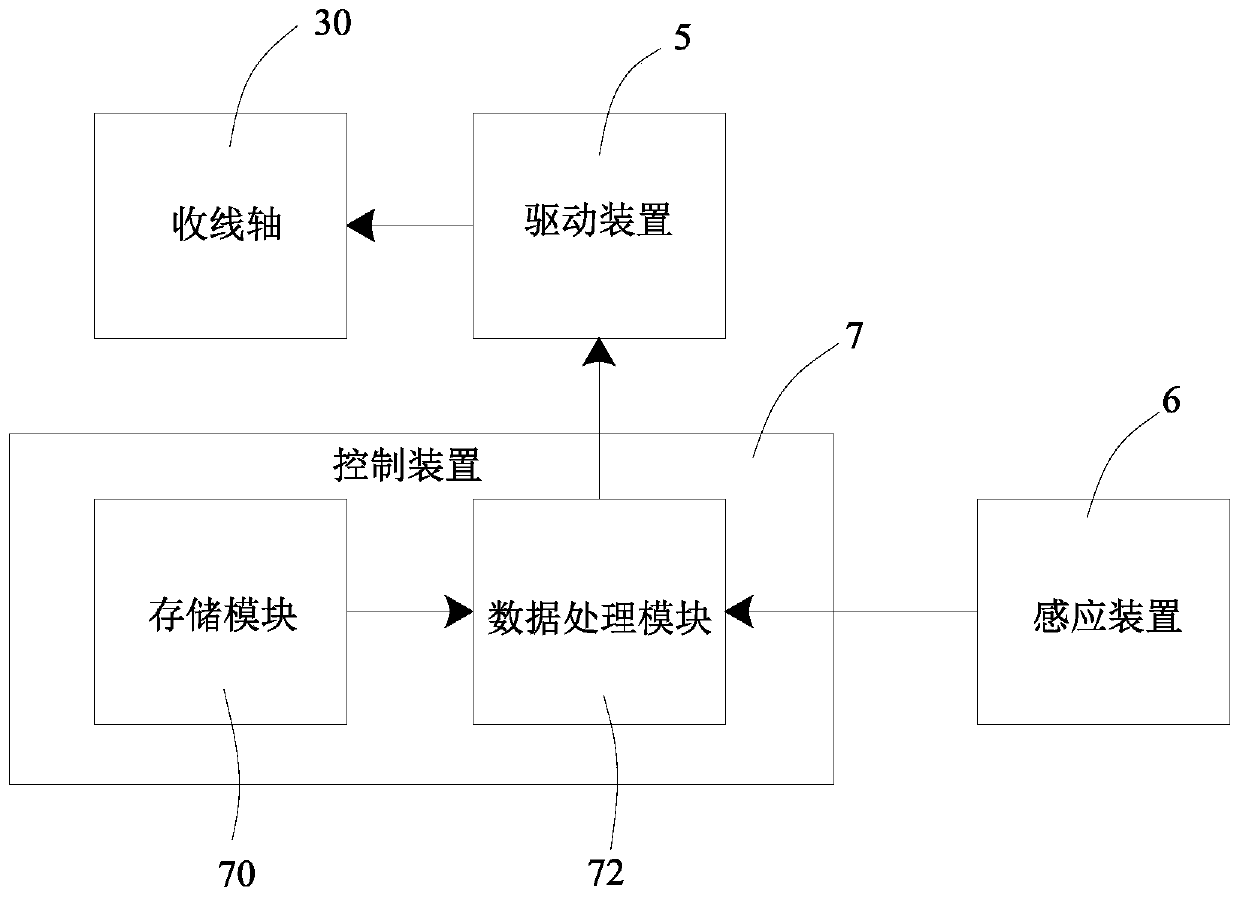

[0019] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides an automatic winding machine, including a feed shaft 1 pivotally provided with a wire supply reel 10 for winding a wire, and a take-up reel 30 for receiving and winding a wire of a predetermined length The take-up shaft 3 coaxially fixed thereon, the driving device 5 for driving the take-up shaft 3 to drive the take-up reel 30 to rotate synchronously for winding, and the induction device 6 for detecting the number of rotations of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com