Stratospheric airship equipment cabin temperature control system

A technology for temperature control systems and stratospheric airships, applied in rigid spaceships, etc., can solve problems such as high power consumption, refrigerant pollution, and insufficient cooling capacity, and achieve the effects of wide application range, low power consumption, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

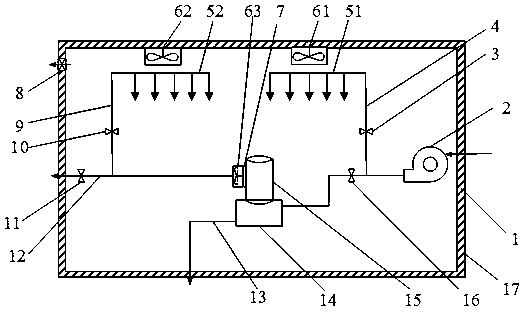

[0017] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

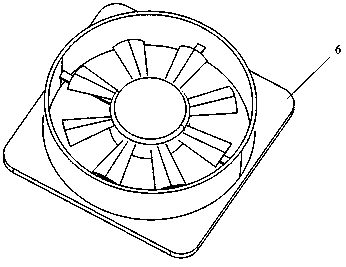

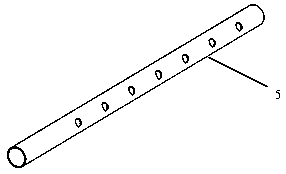

[0018] Such as figure 1 As shown, a stratospheric airship equipment compartment temperature control system includes: a first temperature control system and a second temperature control system; the first temperature control system includes a fan 2, a first pipeline 13, a first valve 16, and a cold plate 14 , the second valve 3, the second pipeline 4, the first flute pipe 51, the first fan 61, one end of the first pipeline 13 is connected with the fan outlet, the other end of the first pipeline 13 leads to the outside of the equipment cabin, and the first pipeline 13 is close to A cold plate 14 is installed on the electronic equipment 15, a first valve 16 is installed on the first pipeline between the cold plate 14 and the fan 2, one end of the second pipeline 4 is connected to the fan 2, and the other end is installed near the top of the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com