Method for preparing metal composite plate through double corrugated roll cross rolling

A metal clad plate and cross-rolling technology, applied in the direction of metal rolling, can solve the problems of poor bonding strength, low elongation, cracking, etc., and achieve the effects of uniform deformation, large elongation, and increased bonding area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

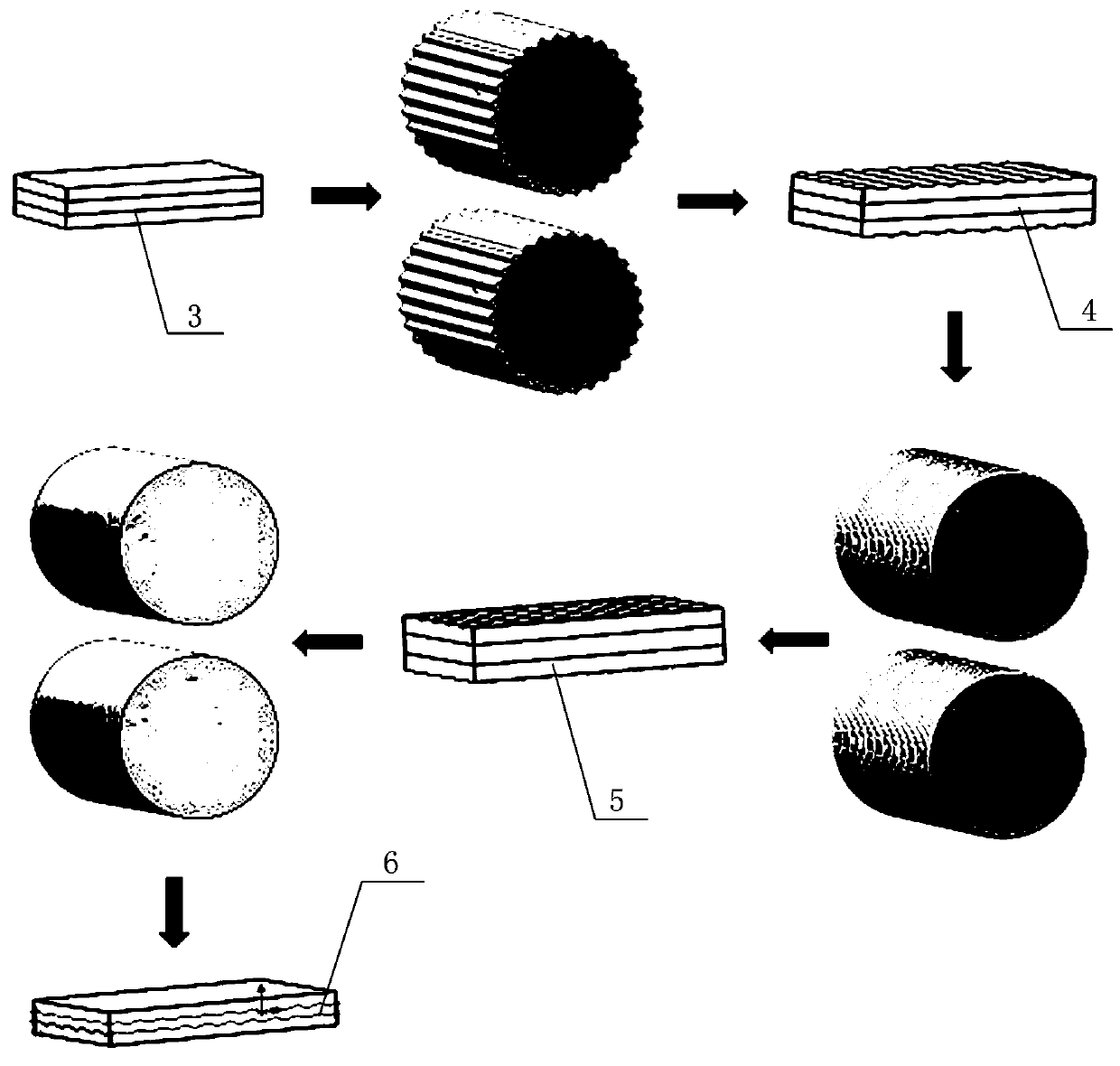

[0033] S1, such as figure 1 As shown, a T2 copper plate with a size of 100mm×20mm×1.5mm is selected as the substrate 1, and two 1060 pure aluminum plates with a size of 100mm×20mm×2.5mm are selected as the cladding plate 2, and the above-mentioned substrate 1 and cladding plate 2 are The surface to be bonded is polished with a wire brush grinder until fresh metal leaks from the surface, then the polished metal surface is cleaned with alcohol, and finally laminated in the order of "aluminum on the upper cladding plate - copper on the base plate - aluminum on the lower cladding plate" put, and bind the head and tail of the stacked blanks with iron wires to make metal composite panel blanks 3;

[0034] S2, refer to figure 2 , the obtained metal clad plate blank 3 is sent to the two-roll rolling mill a for the first rough rolling, the two-roll rolling mill a of this step adopts two corrugated rolls a with the same direction of corrugation, the reduction rate is 50%, rolling The...

Embodiment 2

[0047] S1. Select a 1060 pure aluminum plate with a size of 100mm×20mm×2.5mm as the substrate 1, and select two T2 red copper plates with a size of 100mm×20mm×1.5mm as the cladding plate 2. Combine the surface with a wire brush grinder for grinding until fresh metal leaks from the surface, then clean the polished metal surface with alcohol, and finally stack it in the order of "upper cladding copper - substrate aluminum - lower cladding copper" , binding the head and tail of the stacked blanks with iron wires to make a metal composite plate blank 3;

[0048] S2. Send the obtained metal composite plate blank 3 into the two-roll rolling mill a for the first rough rolling. The two-roll rolling mill a in this step adopts two longitudinal corrugated rolls a with the same corrugation direction, and the reduction rate is 50%. The rolling speed is 0.15m / s, and the plate obtained by the first rough rolling is as follows: Figure 8 As shown, this step is processed to obtain a metal com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com