Environment-protecting grain cleaning and dust removing device

A dust-removing device and an environment-friendly technology, applied in the field of environmental-friendly grain cleaning and dust-removing devices, can solve the problems of respiratory health hazards for operators, serious dust in the working environment, poor dust removal effect, etc., and achieve a clean and environmentally friendly process of dust removal, fast and stable dust removal, and practicality. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

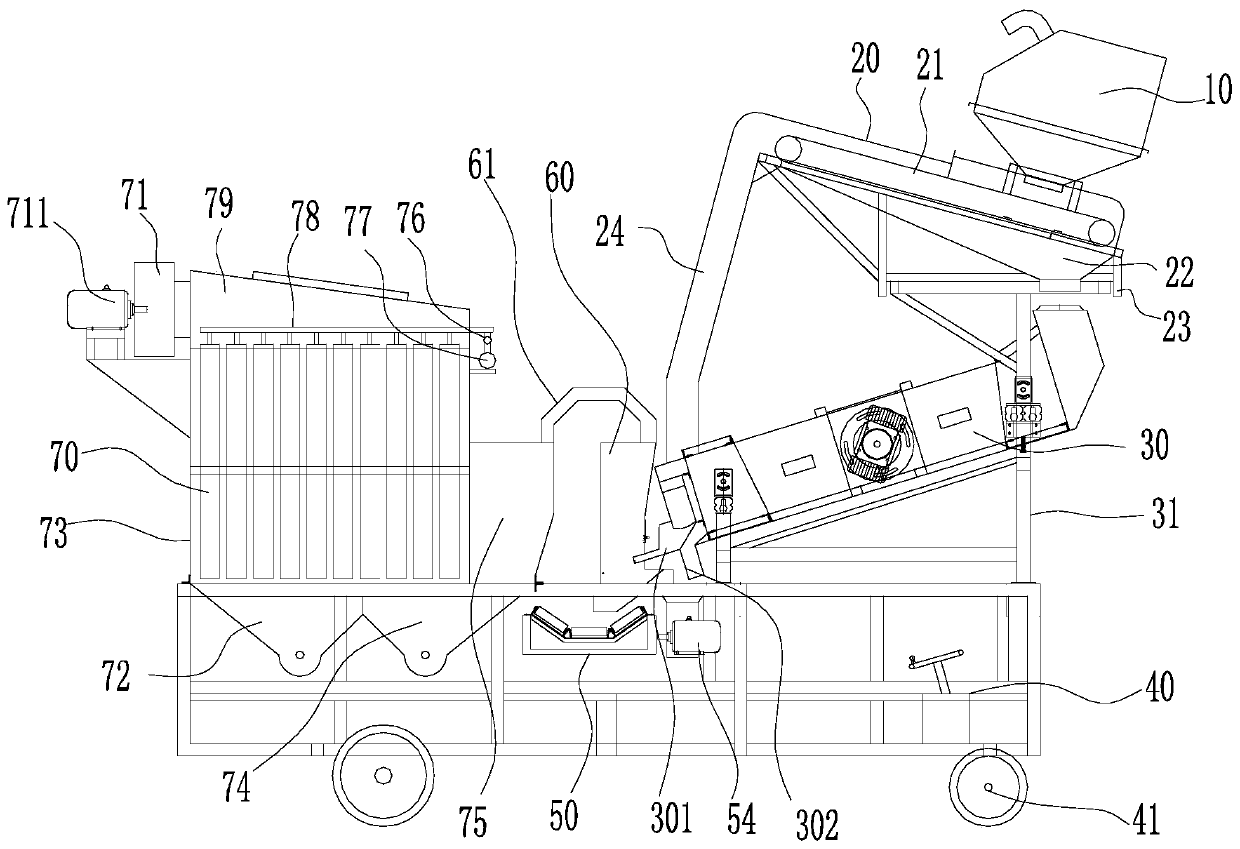

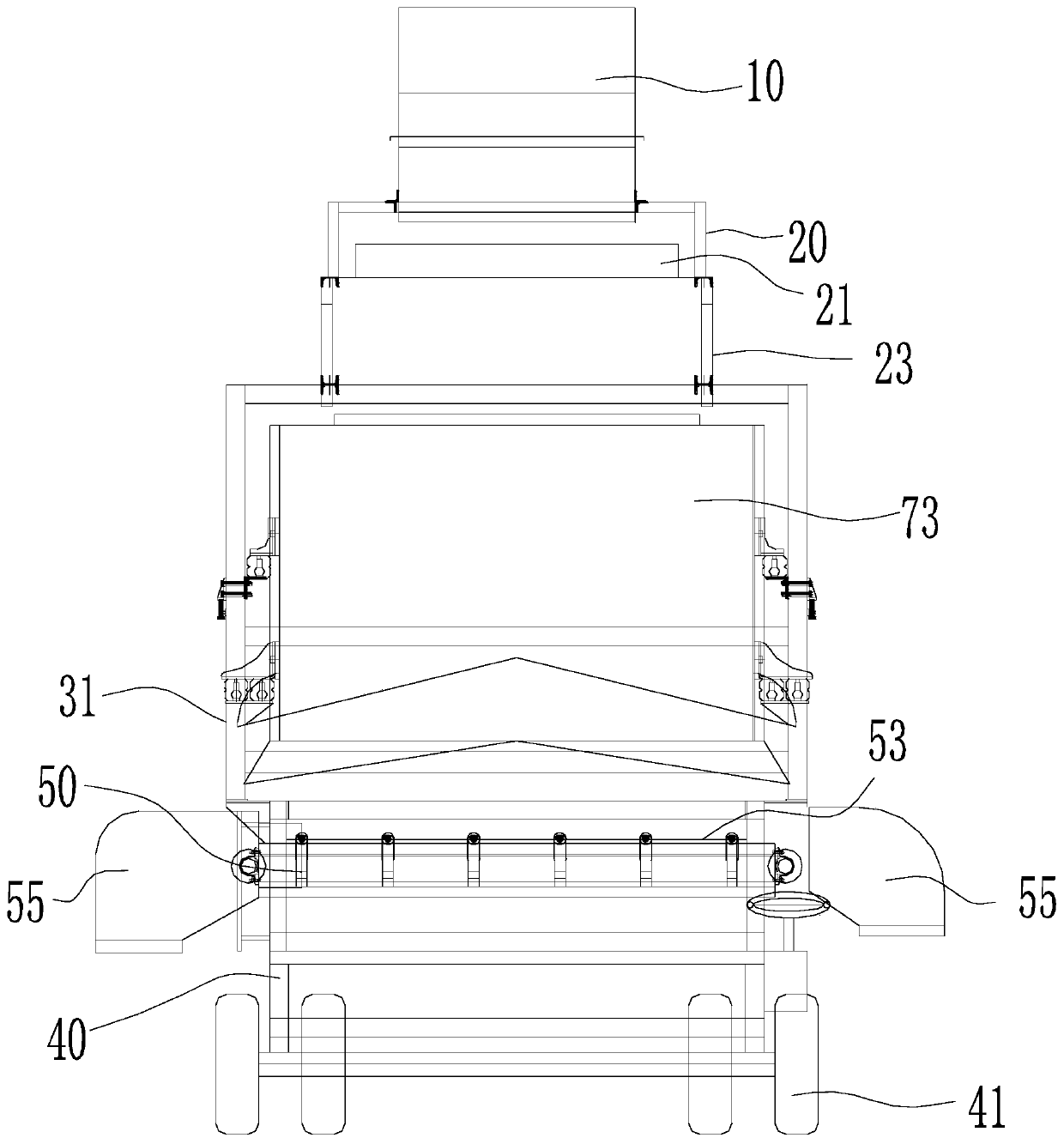

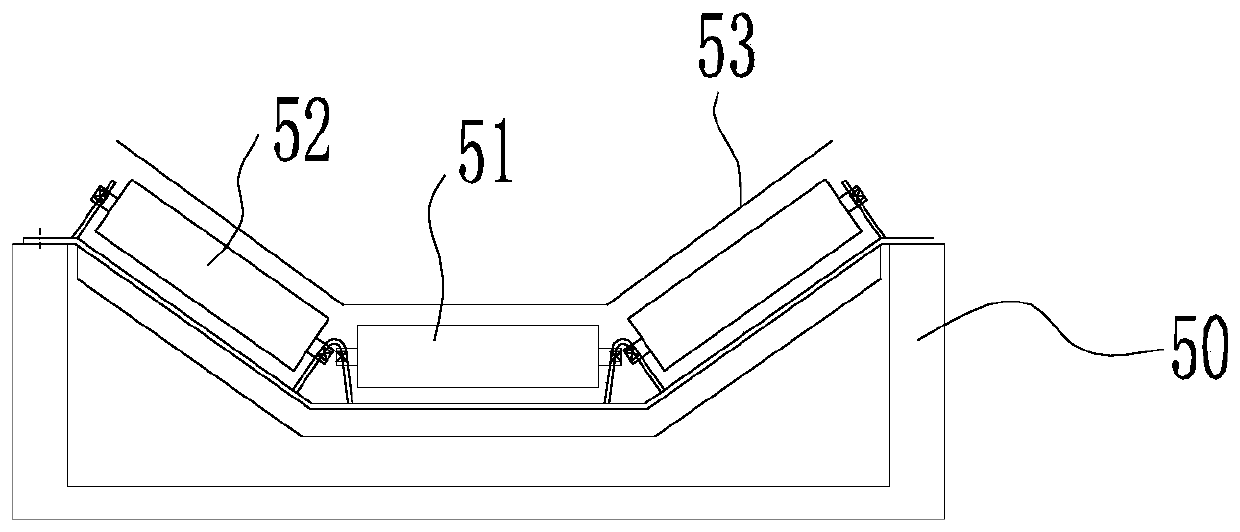

[0022] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides an environmentally friendly grain vibration dust removal device, including:

[0023] The base 40 is provided with a sieve body support 31 at the right end of the base 40, and a double-layer vibrating screen 30 is inclinedly provided on the sieve body support 31, and the lower end of the double-layer vibrating screen 60 is provided with a grain outlet 301 and a miscellaneous outlet 302;

[0024] The dust removal device is arranged on the left side of the double-layer vibrating screen 30, wherein the dust removal device includes a bag filter arranged on the left end of the base 40, an air inlet tube 60 arranged above the grain outlet 301, and the upper end of the air inlet tube 60 is connected There is a suction pipe 61, which is connected to the air inlet 75 of the bag filter, and the air inlet tube 61 is provided with an air volume adjustment device;

[0025] Such as Image 6 , Figure 7 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com