Adjustable uniform distribution atomization test tool

An adjustable and tooling technology, which is applied in the direction of the spraying device, can solve the problems that affect the accuracy of product measurement, the ring body is uneven, and cannot be adjusted, so as to achieve the effect of protecting easy scratches, protecting the appearance quality, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

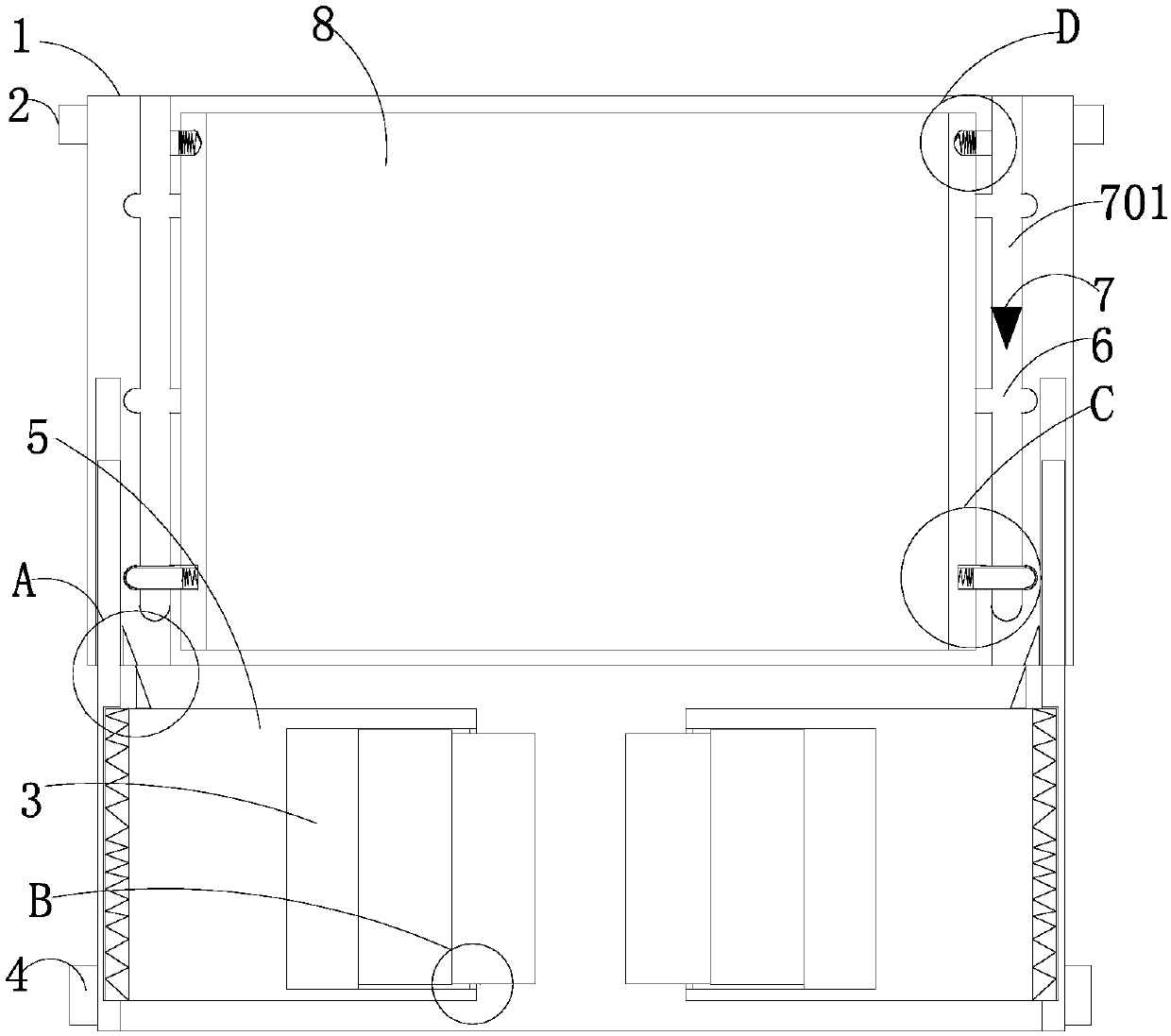

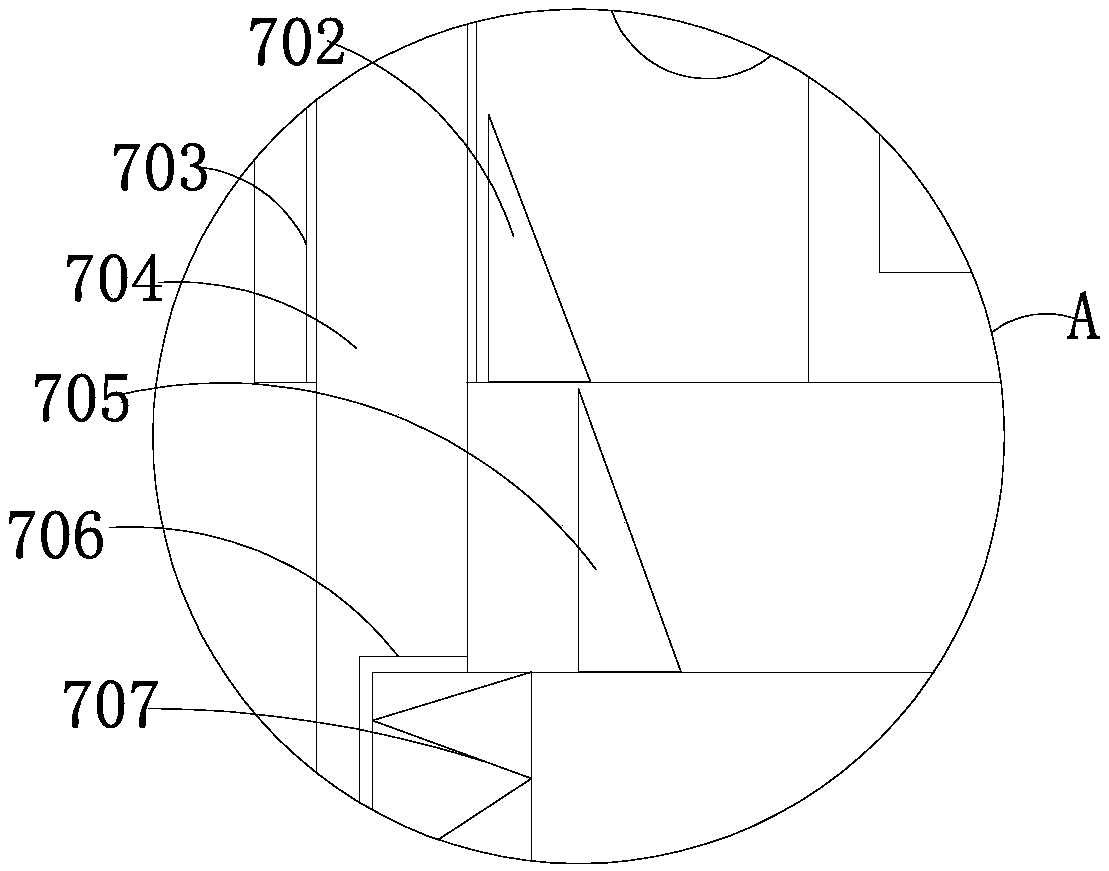

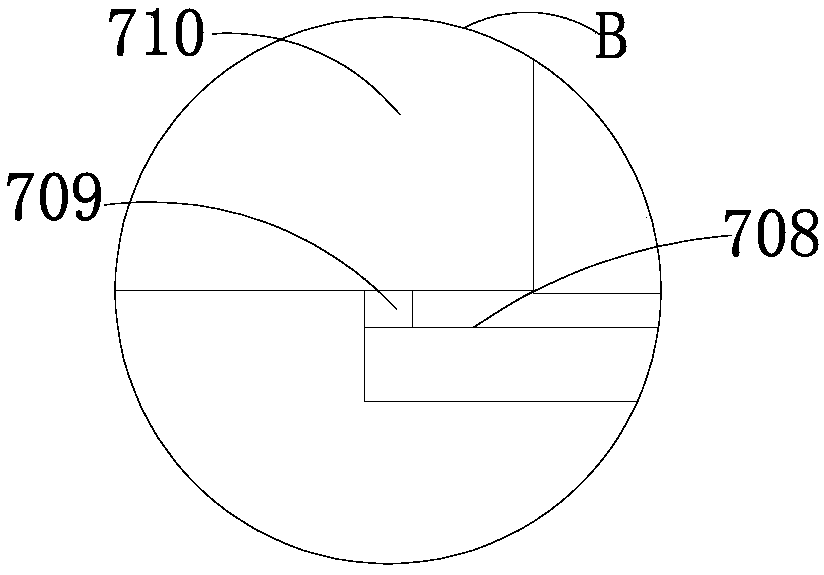

[0024] Such as Figure 1-5As shown, the present invention provides a technical solution: an adjustable uniform atomization test tool, including a main tool tube 1, a primary adjustment cylinder 8 and an adjustable mechanism 7, the adjustable mechanism 7 includes a vertical slideway 701, Triangular deep groove 702, internal thread inner stretching ring 703, movable sleeve 704, triangular raised block 705, long shallow groove 706, long compressed block 707, three-dimensional cavity 708, elastic sealing block 709, telescopic sheet 710, Cylindrical protrusion 711, square inlay groove 712, telescopic block 713, inwardly extending circular groove 714, elastic ring 715 and metal ring 716, a square inlay groove 712 is provided on the bottom side of the outer surface of the primary adjustment cylinder 8, and the main tooling tube 1 One side of the inner surface of the main tooling tube 1 is provided with a vertical vertical slideway 701, and the middle part of the inner surface side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com