Preparation method of noni fermentation liquor for reducing content of methanol

A technology of methanol content and fermentation broth, applied in the functions of food ingredients, food ultrasonic treatment, food science, etc., can solve the problems of long fermentation process time and high concentration of methanol produced by enzymatic hydrolysis, and achieve the reduction of methanol content, large-scale promotion and application. Value, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

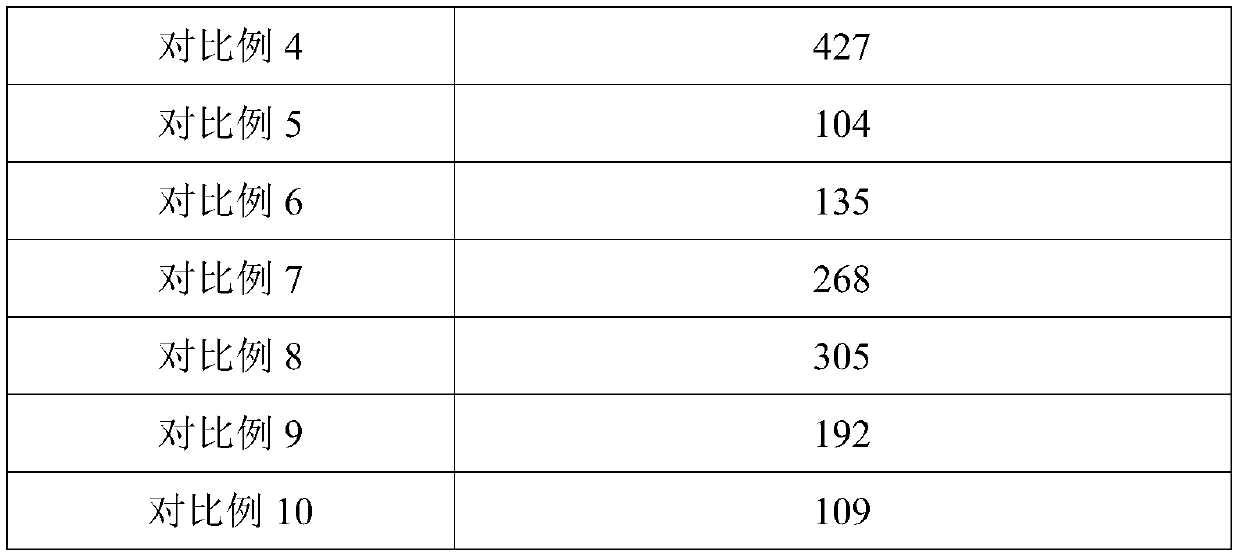

Examples

Embodiment 1

[0027] A method for preparing Noni fermented liquid that reduces methanol content, the production method is as follows:

[0028] (1) Use 50 catties of Hainan Wanning Noni fruit, wash it, squeeze the juice with a juicer, get 12L Noni juice, add 120g CaCl 2 , after stirring evenly, use ultrasonic treatment for 2 minutes, the power of ultrasonic wave is 40W, and the treatment temperature is 25°C; airtight, put it in a cold storage at 5°C for 24h, filter with a 200-mesh filter bag to obtain 11.8L of treated samples, and airtightly control the temperature at 28 ℃ fermentation for 2 months to obtain the noni enzyme sample.

[0029] (2) According to the national standard GB5009.266-2016 gas chromatography, the methanol content of the noni fruit sample was determined to be 1843mg / L, and the noni fruit enzyme was heated to 40°C, and hydrogen peroxide (concentration of 3 to 3.3%) was added. ) 123mL, ultrasonic treatment for 3min, the treatment temperature is 25°C, and the ultrasonic po...

Embodiment 2

[0031] A method for preparing Noni fermented liquid that reduces methanol content, the production method is as follows:

[0032] (1) Use 50 catties of Hainan Wanning Noni fruit, wash and squeeze the juice with a juicer to obtain 12L Noni juice, add 126g of CaCl 2 , after stirring evenly, use ultrasonic treatment for 1.5min, the power of ultrasonic wave is 300W, and the treatment temperature is 25°C; airtight, put it in a cold storage at 15°C for 30h, filter with a 200-mesh filter bag to obtain 11.8L of treated samples, airtightly control the temperature at Fermentation at 28°C for 2 months to obtain the noni enzyme sample.

[0033] (2) Measure the methanol content of the noni fruit sample according to the national standard GB5009.266-2016 gas chromatography to be 1843mg / L, heat the noni fruit enzyme to 45°C, add hydrogen peroxide (concentration is 3 to 3.3%) ) 123mL, ultrasonic treatment for 6min, the treatment temperature is 30°C, and the ultrasonic power is 300W; the treate...

Embodiment 3

[0035] A method for preparing Noni fermented liquid that reduces methanol content, the production method is as follows:

[0036] (1) Use 50 catties of Hainan Wanning Noni fruit, wash it, and squeeze it with a juicer to get 12L Noni juice, add 132g of CaCl 2 , after stirring evenly, use ultrasonic treatment for 5 minutes, the power of ultrasonic wave is 50W, and the treatment temperature is 28°C; airtight, put it in a cold storage at 10°C for 20h, filter with a 200-mesh filter bag to obtain 11.8L of treated samples, and airtightly control the temperature at 28 ℃ fermentation for 2 months to obtain the noni enzyme sample.

[0037] (2) Measure the methanol content of the noni fruit sample according to the national standard GB5009.266-2016 gas chromatography to be 1843mg / L, heat the noni fruit enzyme to 43°C, add hydrogen peroxide (concentration is 3 to 3.3%) ) 123mL, ultrasonic treatment for 5min, the treatment temperature is 28°C, and the ultrasonic power is 200W; the treated non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com