Preparation method and application of three-dimensional self-supporting nitrogen-doped carbon sodium ion negative electrode material

A nitrogen-doped carbon and negative electrode material technology, applied in the field of electrochemical power supply, can solve the problems of high cost, poor safety of carbon materials, and poor cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

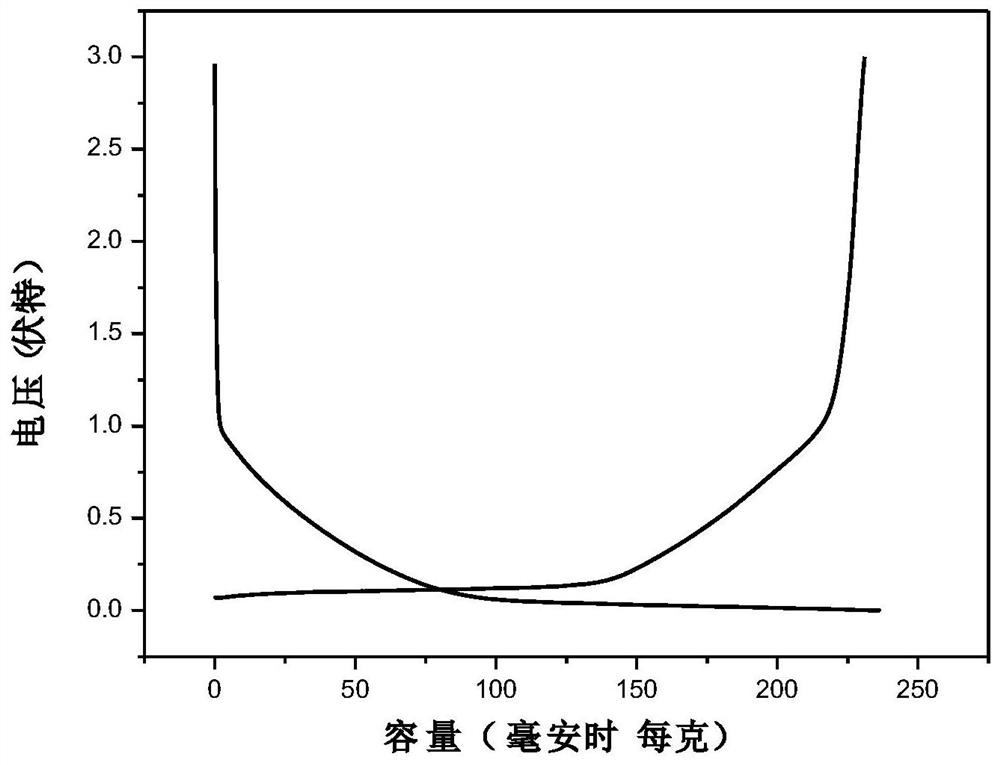

Examples

Embodiment 1

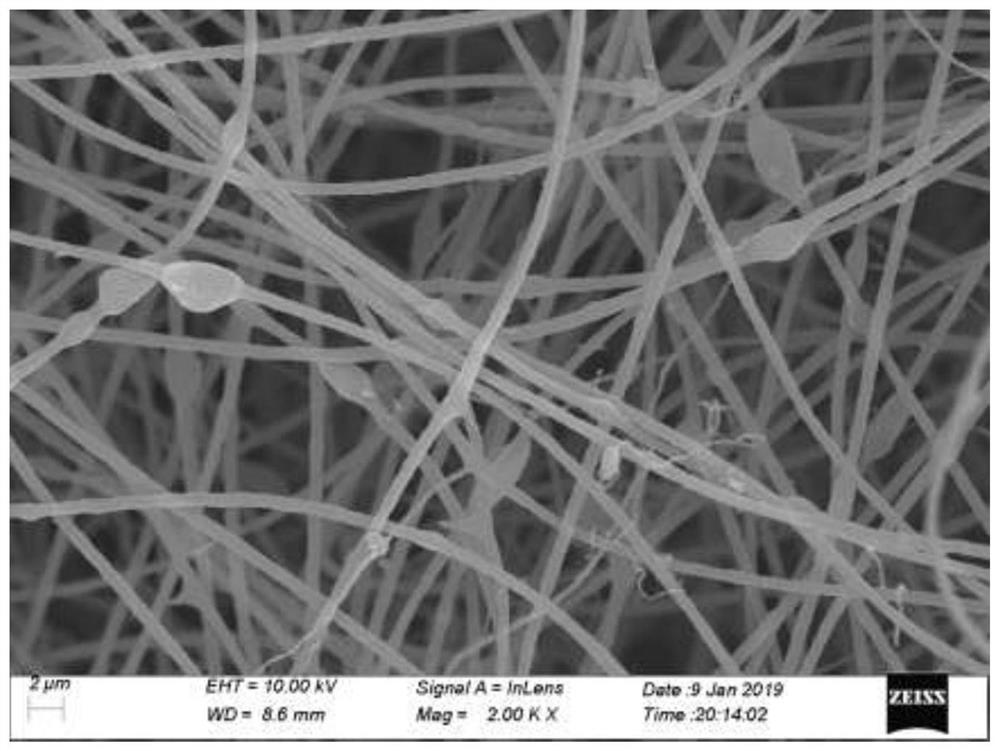

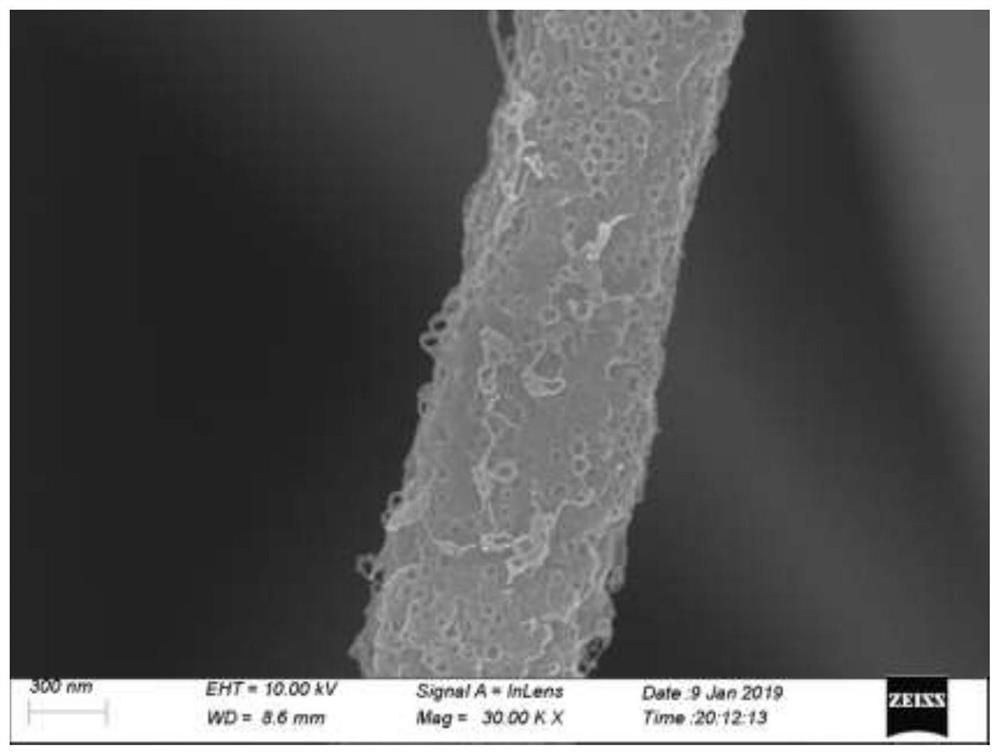

[0036] (1) Preparation of three-dimensional carbon anode materials

[0037] A method for preparing a three-dimensional self-supporting nitrogen-doped carbon-sodium ion negative electrode material, comprising the following steps:

[0038] (1) Preparation of ZIF-8: Take a certain amount of Zn(NO 3 ) 2 ·6H 2O was dissolved in 100ml of methanol to obtain solution A; a certain amount of composite ligand was dissolved in 100ml of methanol to obtain solution B, wherein the composite ligand was composed of a rigid ligand and a flexible ligand in a molar ratio of 1:1. The combination of rigid ligand (2,2-bipyridyl) and flexible ligand (1,2-dipyridylethane) can not only ensure the strength, prevent the collapse of holes, but also improve the flexibility of the material; take a certain amount Poly N-isopropylacrylamide was dissolved in 100ml methanol to obtain solution C; wherein, Zn(NO 3 ) 2 ·6H 2 O, the molar ratio of complex ligand and poly-N-isopropylacrylamide is 1:4:1, the so...

Embodiment 2

[0051] This embodiment is basically the same as Embodiment 1, the difference is:

[0052] A method for preparing a three-dimensional self-supporting nitrogen-doped carbon-sodium ion negative electrode material, comprising the following steps:

[0053] (1) Preparation of ZIF-8: Take a certain amount of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of methanol to obtain solution A; a certain amount of composite ligand was dissolved in 100ml of methanol to obtain solution B, wherein the composite ligand was composed of a rigid ligand and a flexible ligand in a molar ratio of 1:1. The combination of rigid ligand (2,2-bipyridyl) and flexible ligand (1,2-dipyridylethane) can not only ensure the strength, prevent the collapse of holes, but also improve the flexibility of the material; take a certain amount Poly N-isopropylacrylamide was dissolved in 100ml methanol to obtain solution C; wherein, Zn(NO 3 ) 2 ·6H 2 O, the molar ratio of composite ligand and poly-N-isopropylacrylamide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com