An auxiliary downhole drilling tool

A technology for drilling tools and drilling fluids, which is applied in the drilling driving device, drilling equipment, drilling pipe and other directions in the wellbore, and can solve the problems of stuck-jumping, stalling, stick-slip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is introduced below by accompanying drawing.

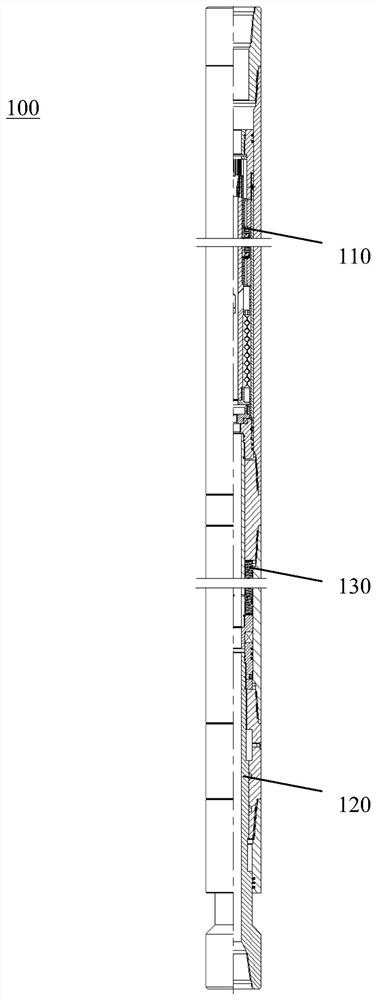

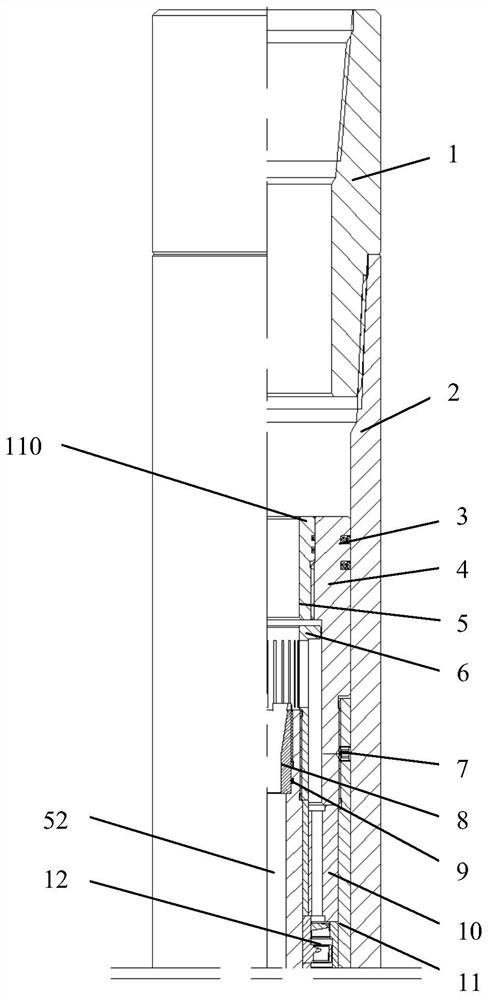

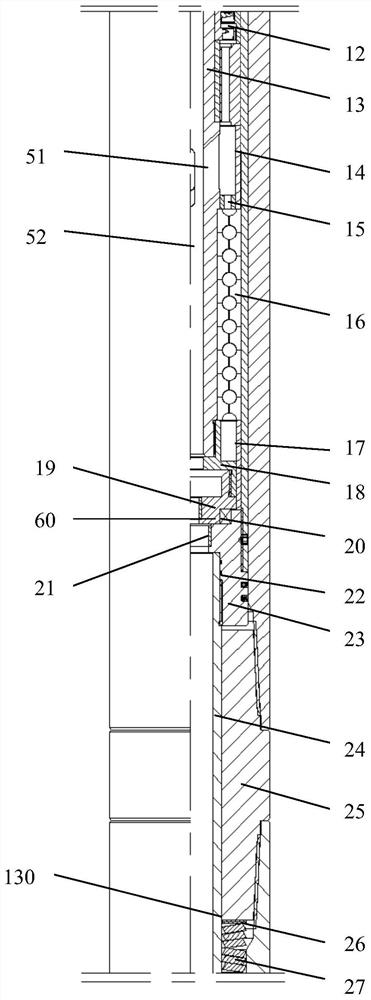

[0028] figure 1 The structure of an auxiliary downhole drilling tool 100 according to the present invention is shown. Such as figure 1 As shown, the auxiliary downhole drilling tool 100 includes an impact energy generator 110 . The impact energy generator 110 is mainly used to convert the energy of the drilling fluid to generate axial impact energy. An impact energy distributor 120 is also provided at the lower end of the impact energy generator 110. The impact energy distributor 120 is mainly used to redistribute the axial impact energy generated by the impact energy generator 110, thereby forming a and the composite impact energy of the circumferential impact energy. Through the impact energy generator 110 and the impact energy distributor 120, the downhole auxiliary drilling tool 100 can provide the drill bit with high-frequency and variable impact force in multiple directions, effectively impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com