Assembled column pestle connected steel structure system and design method thereof

A prefabricated, steel structure technology, applied in computing, building components, building structures, etc., can solve problems such as poor performance of dissipating seismic energy, low seismic performance, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

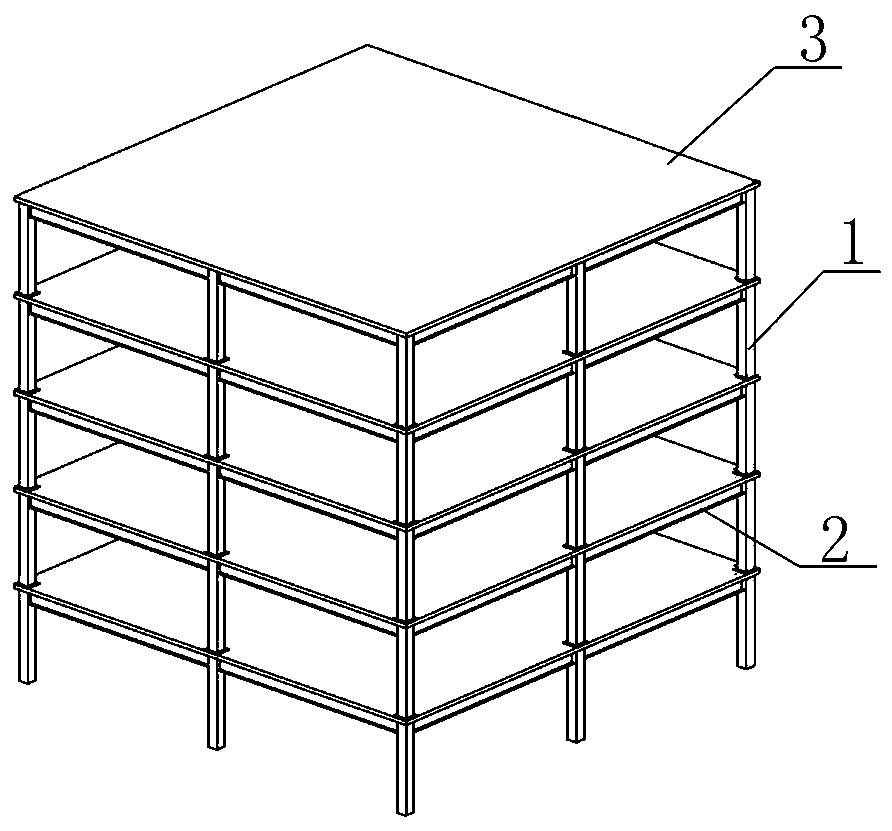

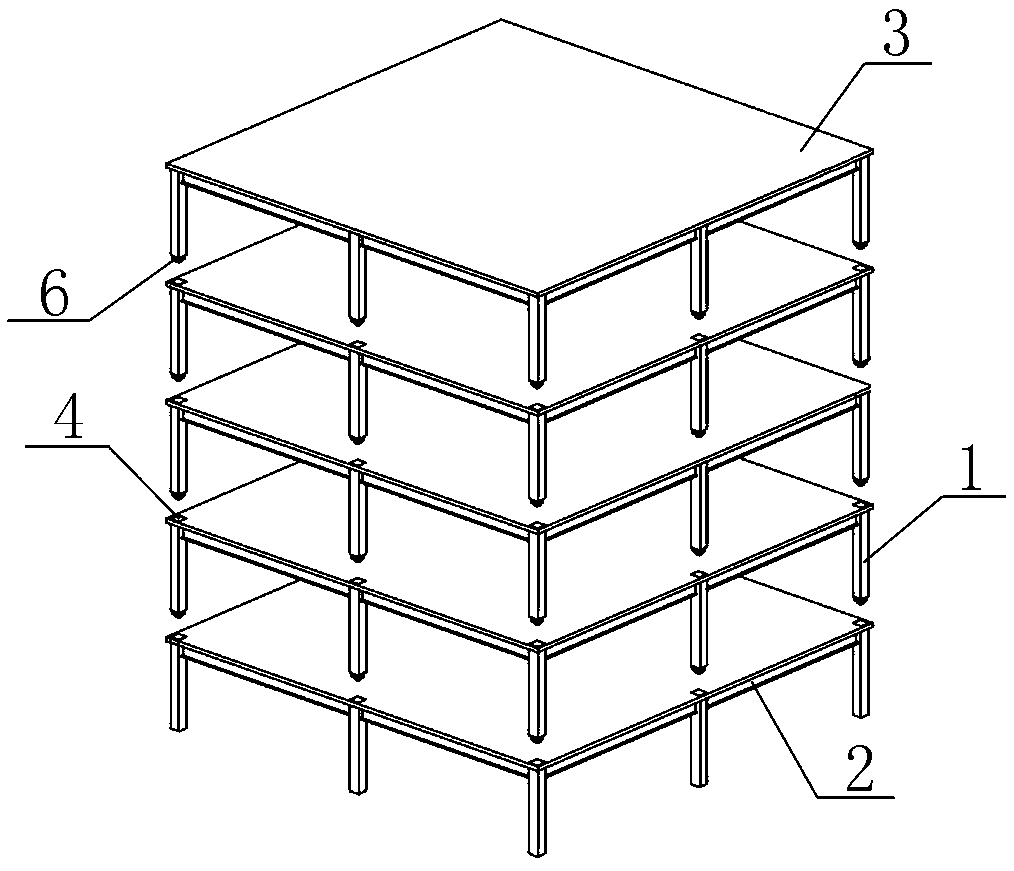

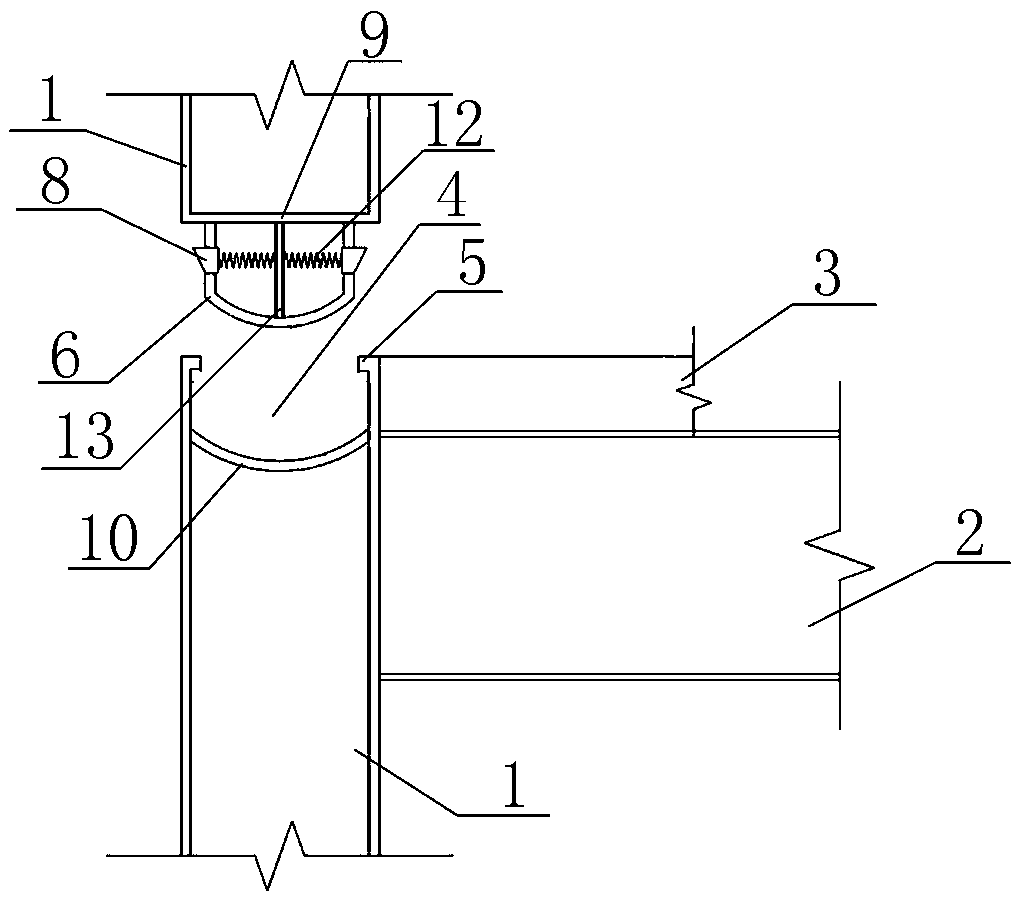

[0088] Such as Figure 1-12 As shown, the steel structure system of this prefabricated column and pestle connection includes at least two layers of steel frame structures stacked vertically; each layer of steel frame structure includes steel columns 1, steel beams 2 and floor slabs 3; wherein, There is a group of steel columns 1 arranged at intervals along the edge of the steel frame structure; there is a group of steel beams 2 correspondingly connected between horizontally adjacent steel columns 1 and vertically adjacent steel columns 1; the floor slab 3 Set on the top of a group of steel beams 2; the steel columns 1 of the vertically adjacent two-story steel frame structures are all disconnected at the connection with the floor 3 of the lower floor, and the columns and pestles are connected between the adjacent two-story steel frame structures; The top of each steel column 1 in the lower steel frame structure is provided with a mortise 4; Horizontal card edge 5; the steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com