A prestressed self-maintaining composite beam without web reinforcement based on slow bonded prestressed UHPC permanent formwork and its construction method

A slow-bonding prestressed, permanent formwork technology, applied in the direction of bridges, bridge construction, bridge materials, etc., can solve the problems of long construction period, etc., and achieve the effect of improving shear resistance, high tensile strength, and increasing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

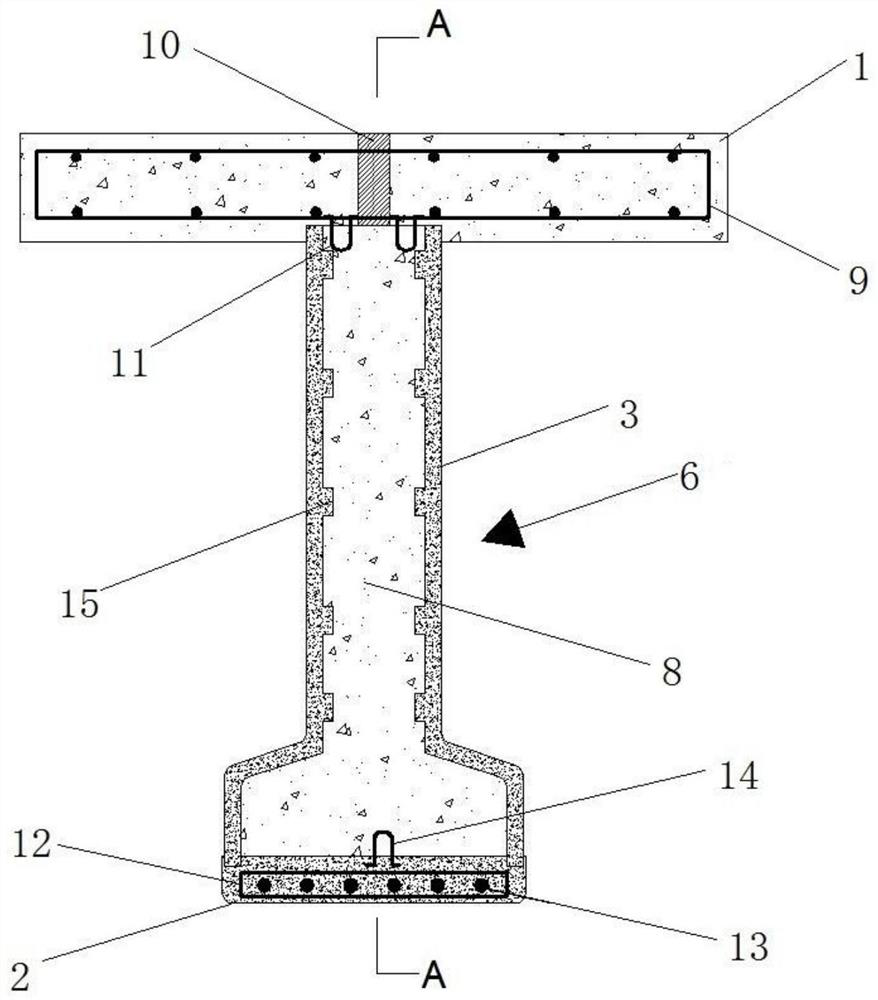

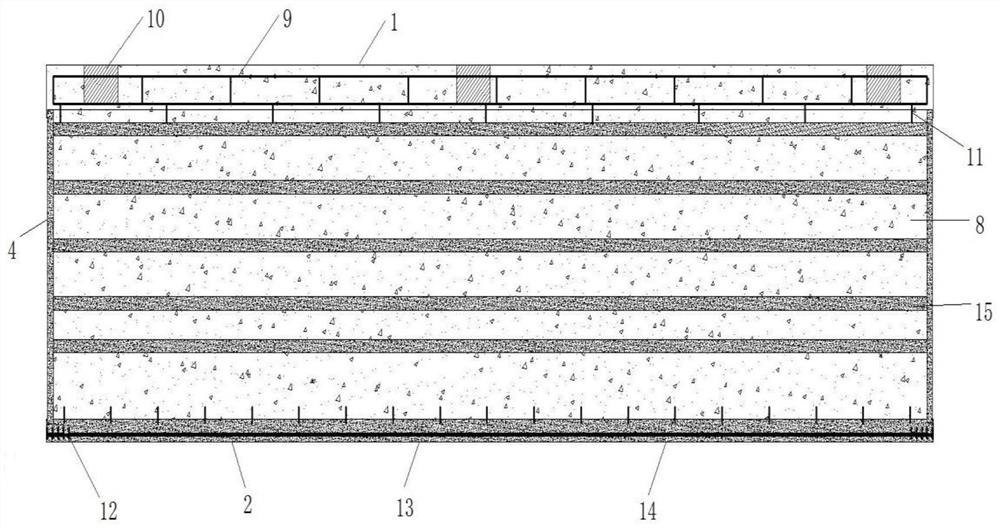

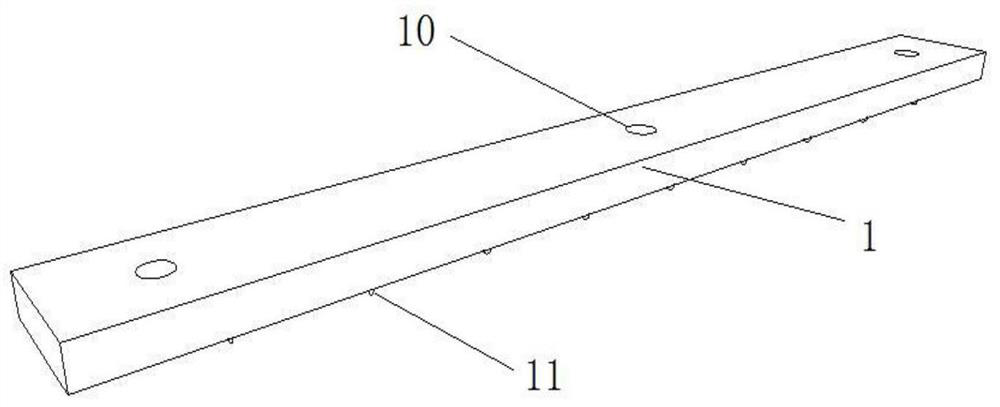

[0034] Such as figure 1 with figure 2 As shown, the present invention is a prestressed self-curing composite beam without web reinforcement based on slow bonding prestressed UHPC permanent formwork. The head plate 4, the base plate 2, the web formwork 3 and the end plate 4 are all prefabricated by ultra-high performance concrete (UHPC). The UHPC strength is 150 MPa, and the fiber content is 2% to 4%. The surface is prefabricated with a return-shaped slot 5, and vertically inserted into the return-shaped slot 5 are two sets of abdominal formwork 3 and two sets of end inserting plates 4, and the two sets of abdominal formwork 3 and two sets of end inserting plates 4 are symmetrical in pairs A beam web body 6 with a rectangular hollow structure is provided, the top plate 1 is prefabricated by high-performance concrete, and the strength of the high-performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com