A prestressed self-maintaining composite beam without web reinforcement based on permanent post-tensioned prestressed uhpc formwork and its construction method

A post-tensioning prestressing and self-maintenance technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve problems such as long construction period, achieve the effect of improving shear resistance, increasing stiffness, and solving cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

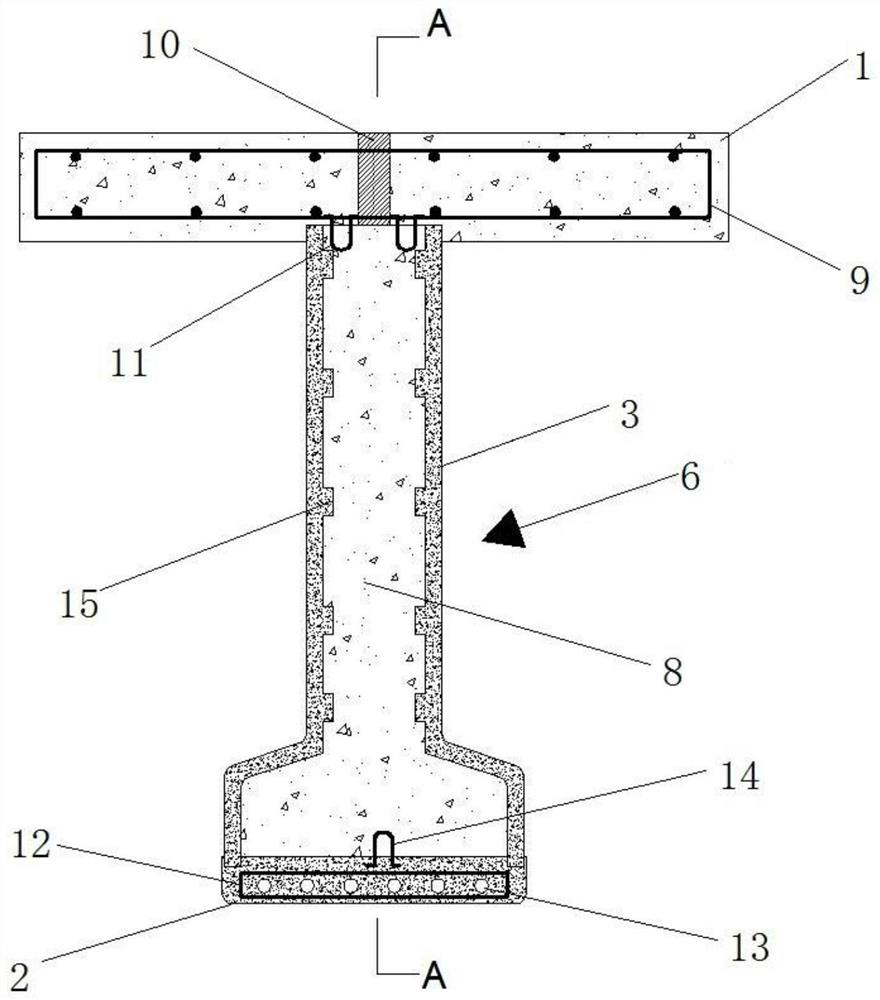

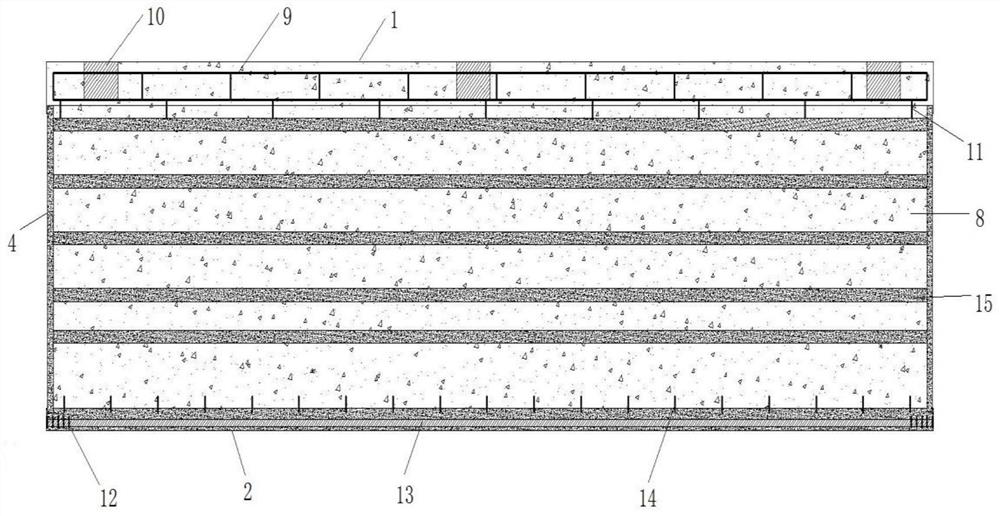

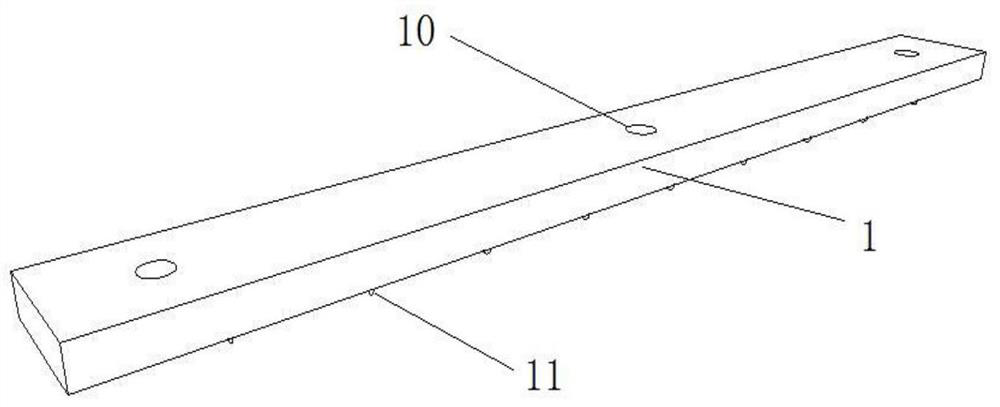

[0036] Such as figure 1 and figure 2 As shown, a prestressed self-curing composite beam without web reinforcement based on permanent post-tensioned prestressed UHPC suit formwork of the present invention includes a top plate 1, a suit formwork and self-curing concrete 8, and the suit formwork includes a base plate 2, a web formwork 3 and The end plate 4, the base plate 2, the web formwork 3 and the end plate 4 are all prefabricated by ultra-high performance concrete (UHPC), the UHPC strength is 150MPa, the fiber content is 2% to 4%, The upper surface is prefabricated with a return-shaped slot 5, and vertically inserted in the return-shaped slot 5 are two sets of abdominal formwork 3 and two sets of end inserting plates 4, and two sets of abdominal formwork 3 and two sets of end inserting plates 4 are arranged in pairs. The beam web body 6 is symmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com