Cortex eucommiae soap and preparation method thereof

A technology of soap and Eucommia fine powder, which is applied in soap detergents and other compounding agents, chemical instruments and methods, soap detergent compositions, etc., and can solve chemical extraction reagent residues, skin side effects, skin irritation, etc. problems, to achieve the effect of excellent comprehensive performance, wide applicability and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Weighing by parts by weight: 80 parts of rapeseed oil, 20 parts of olive oil, 10 parts of Eucommia fine powder, 10 parts of sodium hydroxide, 20 parts of distilled water, and 10 parts of pure milk.

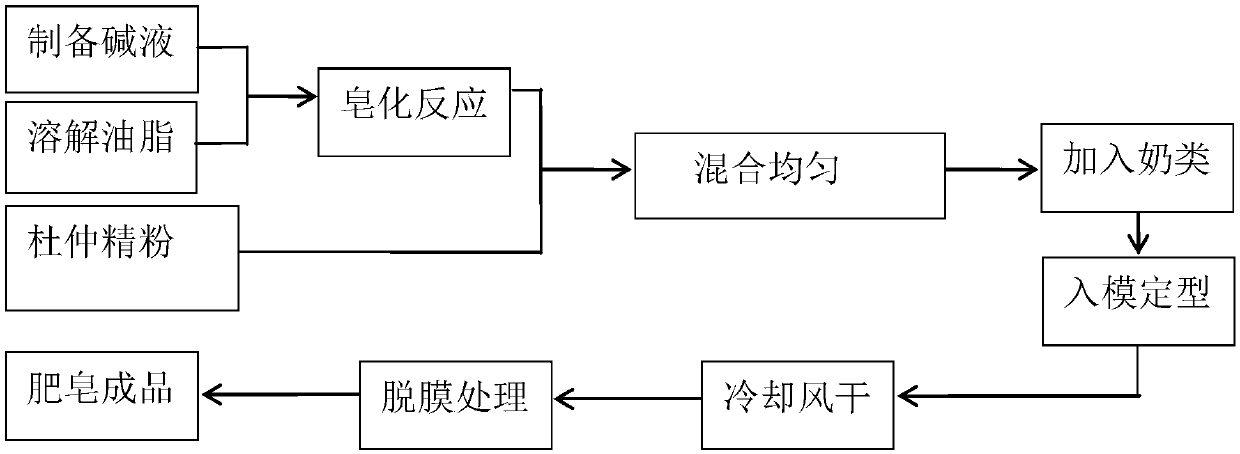

[0044] The concrete preparation method of eucommia soap comprises the following steps:

[0045] 1. Add sodium hydroxide to distilled water to make lye;

[0046] 2. Mix rapeseed oil and olive oil into a beaker and heat to 50°C on an electromagnetic heating mantle;

[0047] 3. Cool the lye to 50°C and pour it into the heated mixed oil, stir evenly to obtain a mixed solution;

[0048] 4. Add the weighed eucommia powder into the above mixed solution, stir until it is paste-like and there is no grease layer on the surface, then slowly add pure milk to obtain thick soap;

[0049] 5. Pour the thick soap liquid into a resin mold, keep it warm for 48 hours in a ventilated and cool environment at 25°C, then take out the solid in the mold, and slice it to make Eucommia soap.

Embodiment 2

[0051] Weighing by parts by weight: 60 parts of rapeseed oil, 40 parts of olive oil, 10 parts of Eucommia fine powder, 10 parts of sodium hydroxide, 20 parts of tap water, and 10 parts of pure milk.

[0052] The concrete preparation method of eucommia soap comprises the following steps:

[0053] 1. Add sodium hydroxide to tap water to make lye;

[0054] 2. Mix rapeseed oil and olive oil into a beaker and heat to 50°C on an electromagnetic heating mantle;

[0055] 3. Cool the lye to 50°C and pour it into the heated mixed oil, stir evenly to obtain a mixed solution;

[0056] 4. Add the weighed eucommia powder into the above mixed solution, stir until it is paste-like and there is no grease layer on the surface, then slowly add pure milk to obtain thick soap;

[0057] 5. Pour the thick soap liquid into a resin mold, keep it warm for 72 hours in a ventilated and cool environment at 25°C, then take out the solid in the mold, and slice it to make Eucommia soap.

Embodiment 3

[0059] Weigh by weight: 80 parts of rapeseed oil, 20 parts of olive oil, 10 parts of Eucommia fine powder, 10 parts of sodium hydroxide, 20 parts of tap water, 10 parts of pure milk, 1 part of Meixin Yashe milk essence, Meixin Yashe 1 part of green pigment.

[0060] The concrete preparation method of eucommia soap comprises the following steps:

[0061] 1. Add sodium hydroxide to tap water to make lye;

[0062] 2. Mix rapeseed oil and olive oil into a beaker and heat to 50°C on an electromagnetic heating mantle;

[0063] 3. Cool the lye to 50°C and pour it into the heated mixed oil, stir evenly to obtain mixed soap;

[0064] 4. Add the weighed Eucommia fine powder into the mixed soap liquid, and stir until it becomes a paste and there is no grease layer on the surface;

[0065] 5. Add pure milk, essence, and coloring material to the above mixed soap, stir until the color of the soap is uniform and stable, and a thick soap is obtained;

[0066] 6. Pour the thick soap soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com