Plate pressing device for intelligent manufacturing and counting mechanism thereof

A pressing device and intelligent manufacturing technology, applied in the direction of lamination device, lamination, lamination auxiliary operation, etc., can solve the problems of automatic counting of unprocessed plates, thermal expansion of hydraulic oil, low processing efficiency, etc., and achieve simple structure , Guaranteed integrity and low economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

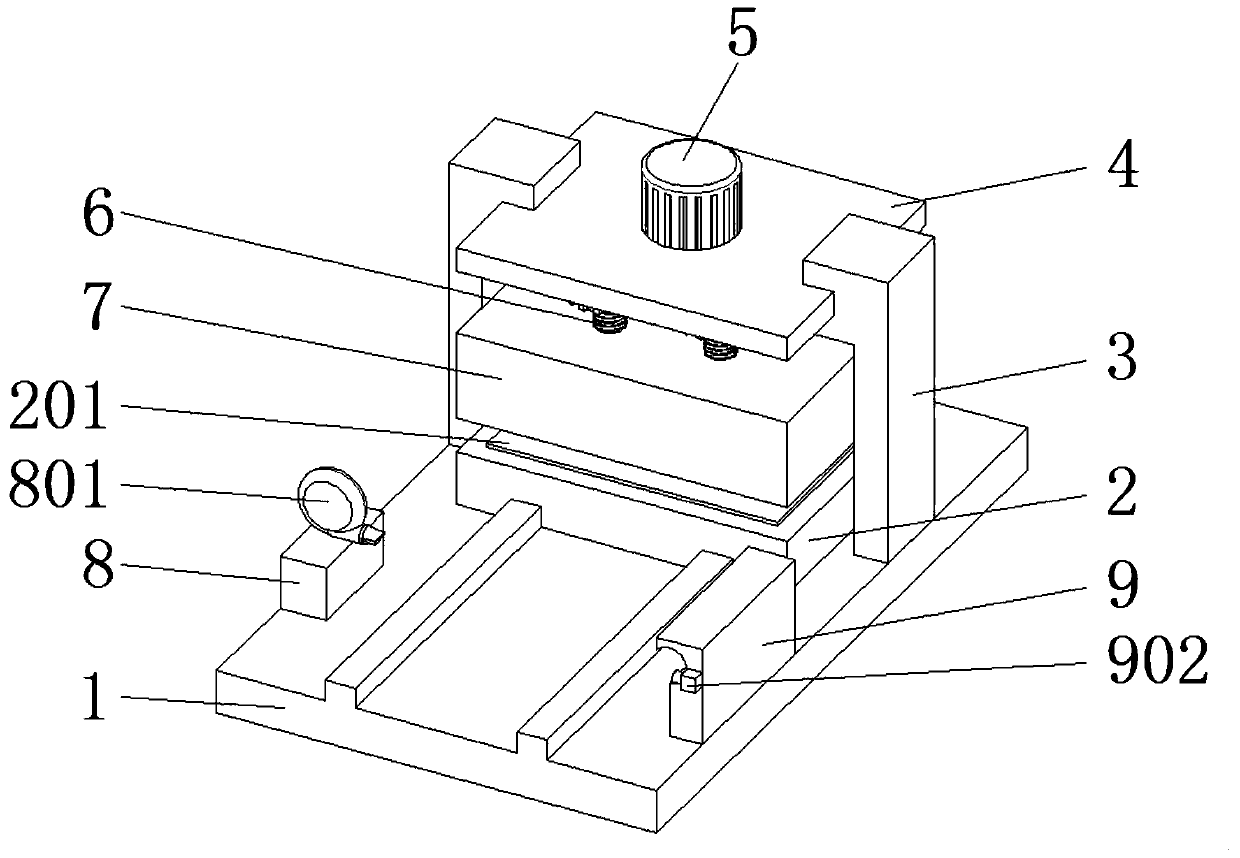

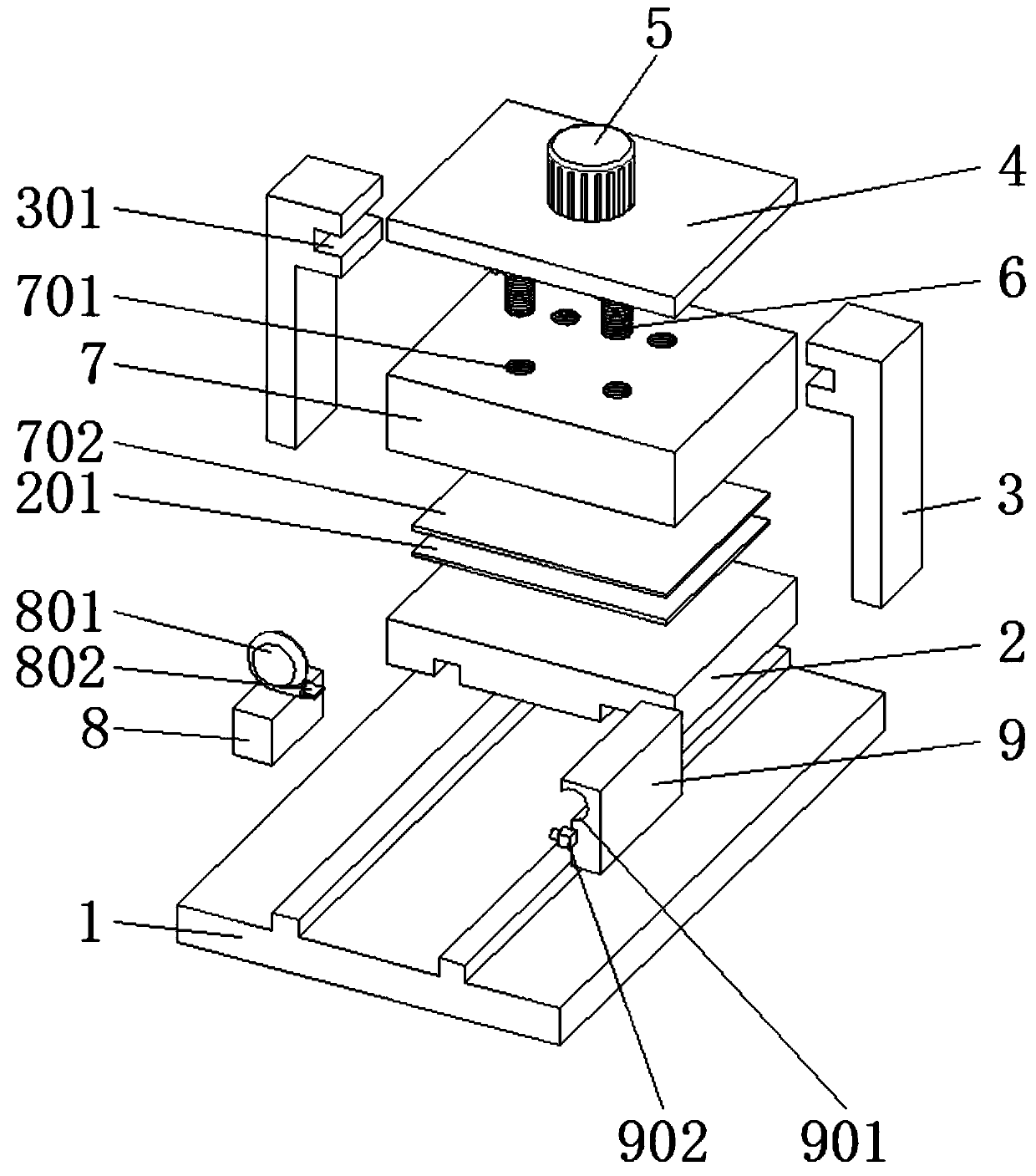

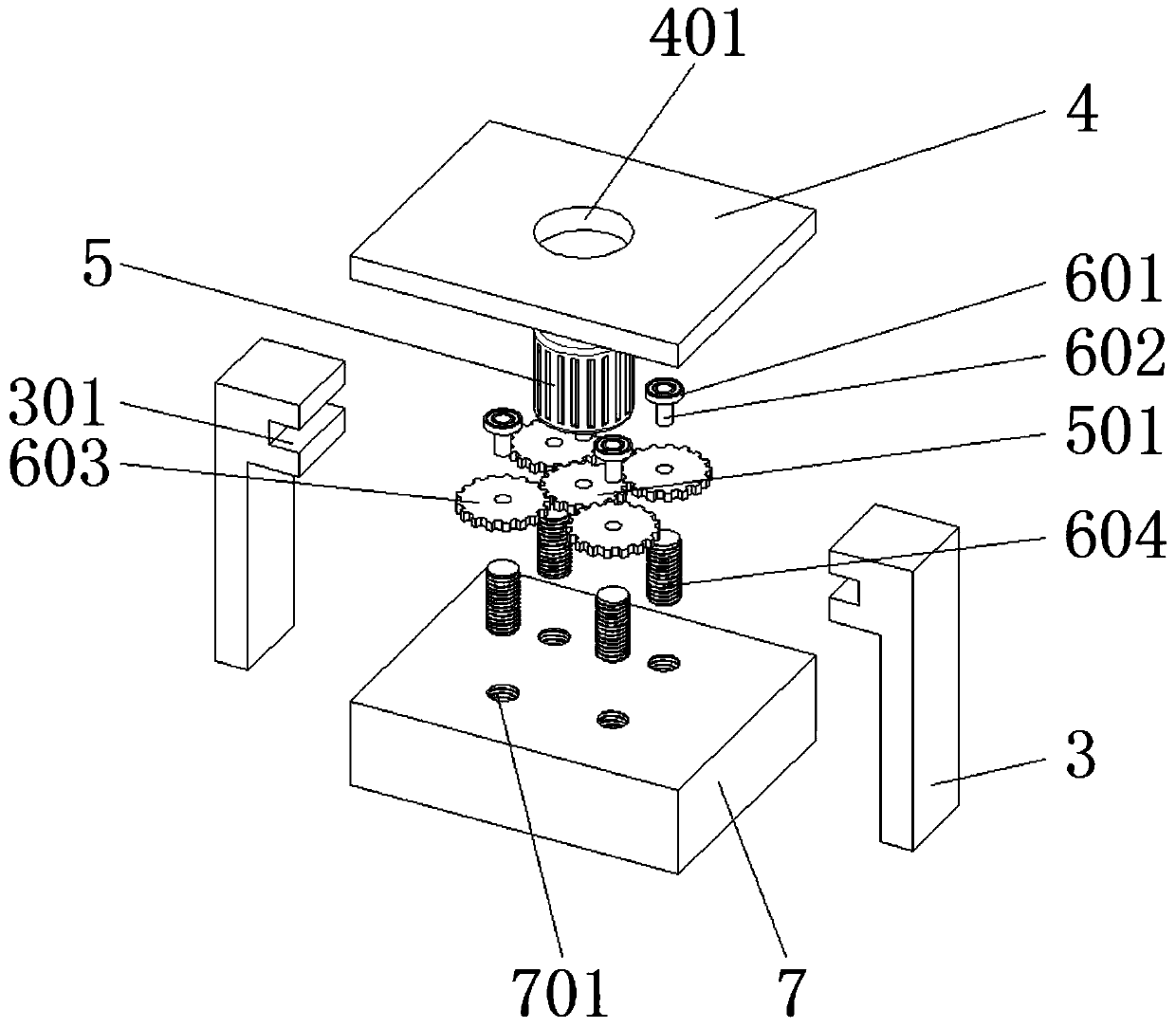

[0023] see Figure 1-5 , the sheet pressing device for intelligent manufacturing and its counting mechanism include a workbench 1, a sliding base 2, a bottom plate 201, a pressing block 7 and a top plate 702, and a bracket 3 is fixedly installed on the rear side of the top surface of the workbench 1 for Press-down mechanism is installed, the quantity of support 3 is two, two support 3 are symmetrically distributed on the top surface of workbench 1, can bear the gravity of press-down mechanism evenly, the top of support 3 offers fixing groove 301, is used for L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com