Movable stacking robot

A palletizing robot and mobile technology, applied in the field of robots, can solve the problems of heavy machine weight, difficult to move, and high motor power, and achieve the effect of reducing motor power, weight and weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

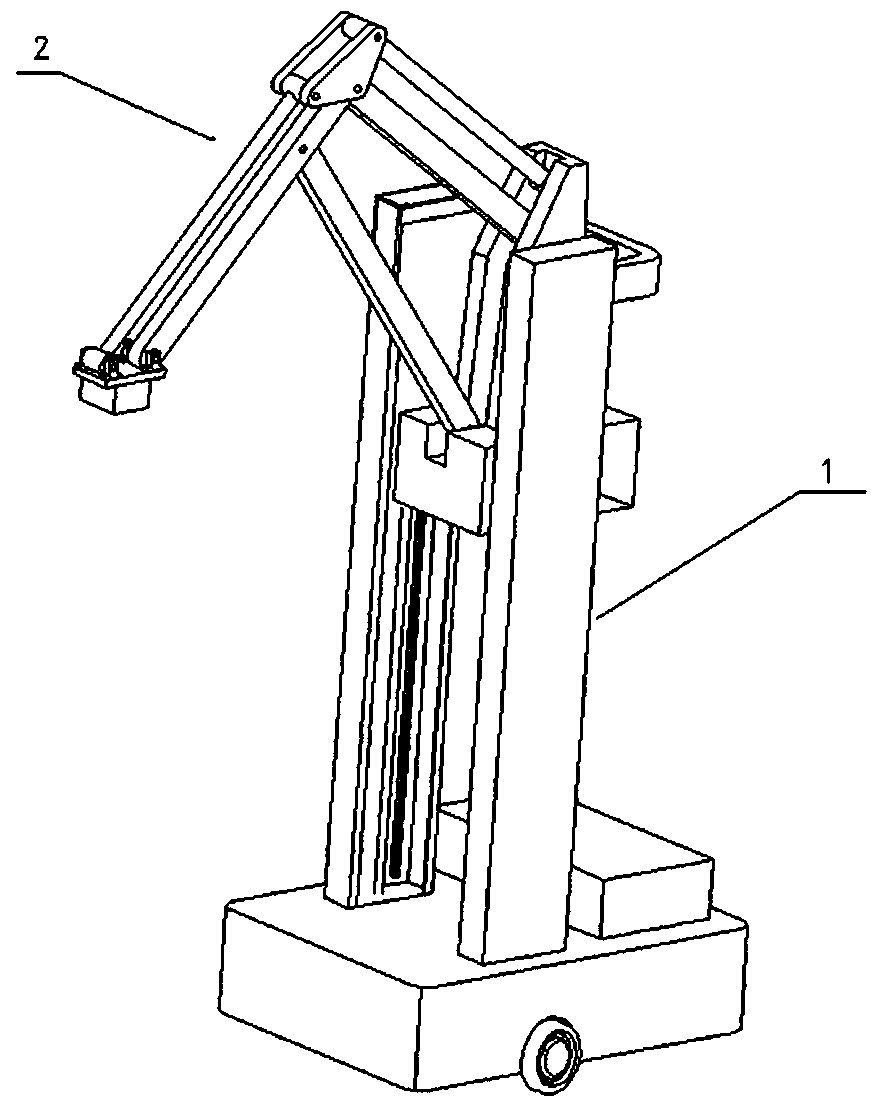

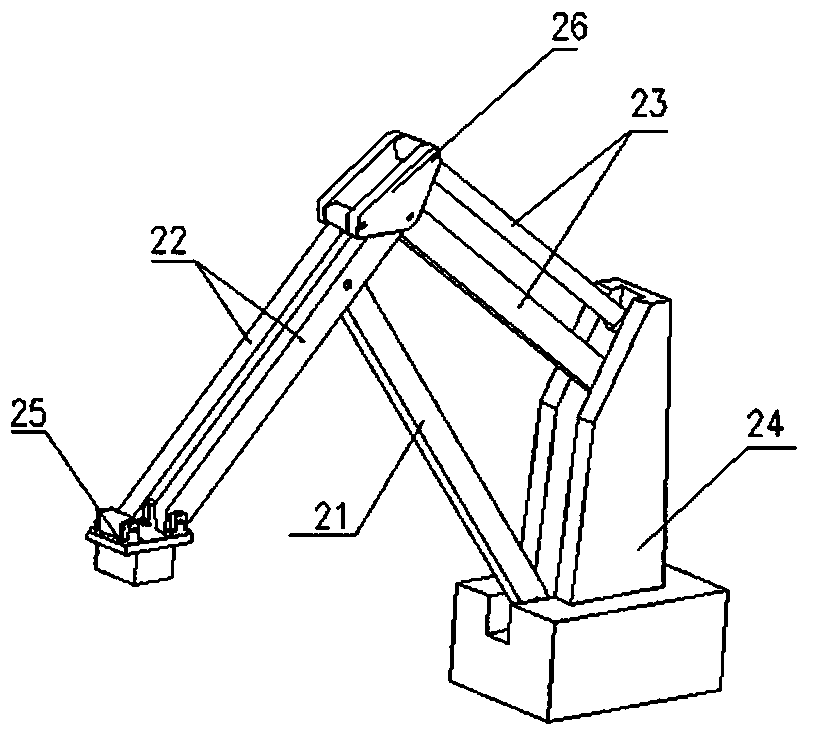

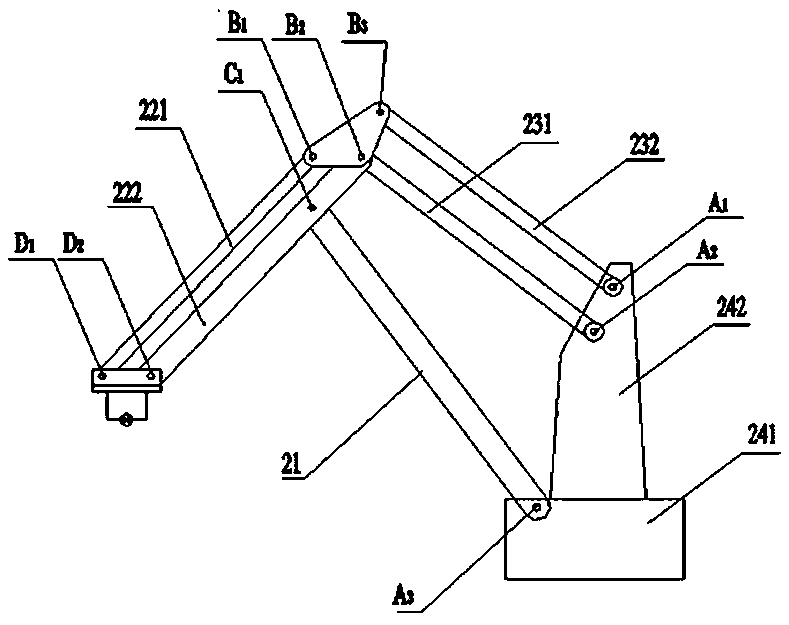

[0030] refer to figure 1 , this figure is a schematic structural diagram of the mobile palletizing robot provided by the embodiment of the present invention. The palletizing robot in this embodiment is used to realize the grabbing of goods in workplaces such as workshops, docks, warehouses, etc., and move them to designated locations , Stack the goods neatly, greatly saving manpower. The mobile palletizing robot of the present invention includes a mobile lifting column 1 and a mechanism-type telescopic arm 2. The mobile lifting column 1 brings the mechanism-type telescopic arm 2 to the target cargo according to the palletizing instruction received, and the lifting drive assembly of the mobile lifting column 1 drives The mechanism-type telescopic arm 2 moves in the vertical direction, adjust the height of the mechanism-type telescopic arm 2, so that the gripper of the mechanism-type telescopic arm 2 matches the height of the target goods, and at the same time through the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com