A processing method for the helical gear sleeve of the lower gear roller mechanical scoring machine

A processing method and scoring machine technology, applied in the field of oriented silicon steel production equipment, can solve the problems of silicon steel slipping, inconvenient, affecting processing quality, etc., achieve the effect of small force, increase contact area, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

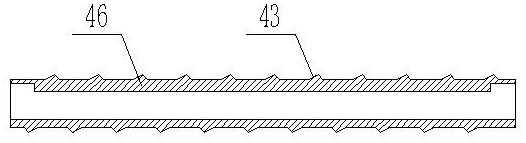

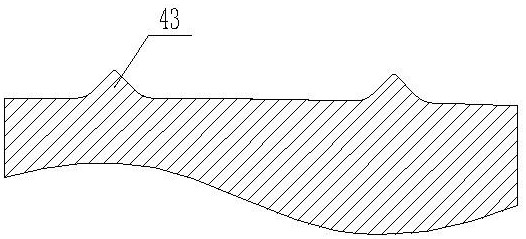

[0050] Such as figure 1 and figure 2 As shown, the present invention is a helical tooth sleeve used for a lower toothed roller mechanical scoring machine. The helical tooth sleeve is a tubular structure with two ends open. The strip-shaped protrusion 46, the outer tube wall of the helical tooth sleeve is provided with annular teeth 43, the outer ring of the annular teeth 43 is an annular edge, and the two adjacent edge surfaces of the annular edge The included angle between them is 90°, and the included angle between the annular teeth 43 and the end surfaces on both sides of the helical tooth sleeve is 8°.

[0051] The processing method for the helical gear sleeve of the lower gear roller type mechanical scoring machine comprises the following steps:

[0052] 1) Prepare raw materials: select high-speed steel ingots as raw materials for helical gear sleeves;

[0053] 2) Forging raw materials: Use a forging machine to forge the raw materials. The raw materials are forged int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com