Method for processing crankshaft oil hole cleanliness

A technology of crankshaft oil hole and processing method, which is applied in the directions of crankshaft, shaft, shaft and bearing, etc., can solve the problems of oil hole cleanliness exceeding poor and difficult to completely remove, etc., and achieve the effect of improving the cleanliness level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] A method for processing crankshaft oil hole cleanliness includes the following steps:

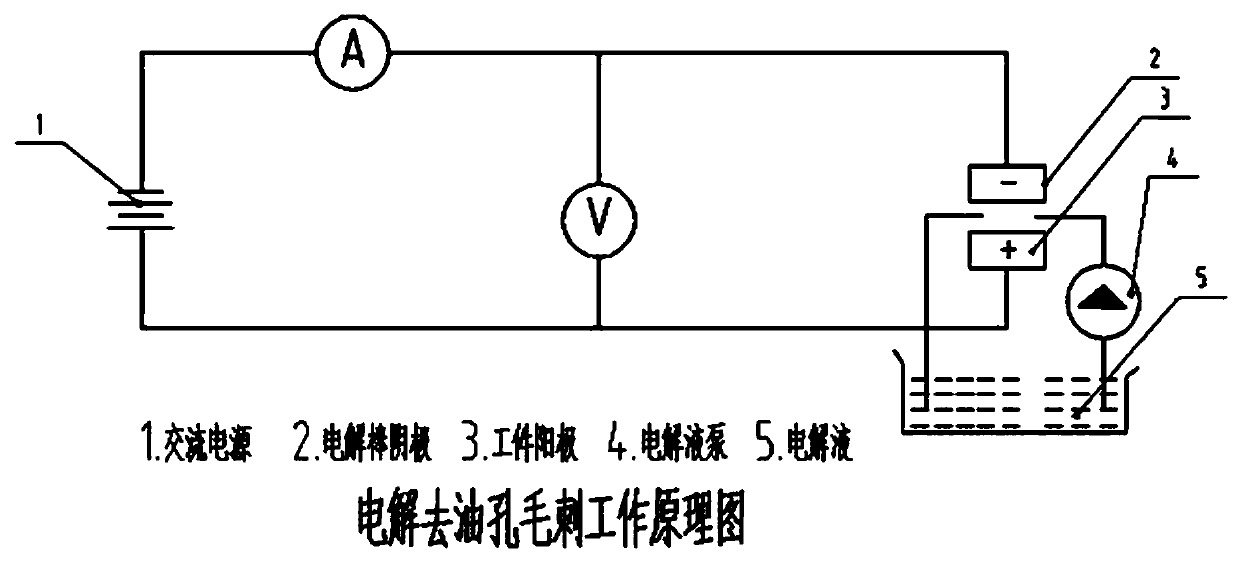

[0042] 1) Electrolysis to remove oil pore burrs, the schematic diagram of the principle of electrolysis to remove oil pore burrs is as follows figure 1 As shown, the working principle of electrolytic degreasing hole burr is to use electric energy and chemical energy to dissolve and deburr the anode. The parts are connected to the positive electrode of the AC power source, called anode, and the electrolytic rod is connected to the negative electrode of the AC power source, called cathode. Keep a certain gap between the two poles to allow the circulating electrolyte to flow. When the surface of the anode and the cathode undergo an electrochemical reaction, the surface of the part will form a layer of viscous liquid due to the re-dissolved metal and the electrolyte. Concentrated in the low recesses on the surface of the part, this viscous liquid has a higher resistance and a lower conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com