High-efficiency 309Nb single-layer strip surfacing sintering flux used in EQ309LNb welding strip and preparation method thereof

A technology of sintering flux and 309nb, which is applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as unrealizable and cooperative welding, and achieve the effect of improving work efficiency and shortening the manufacturing period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

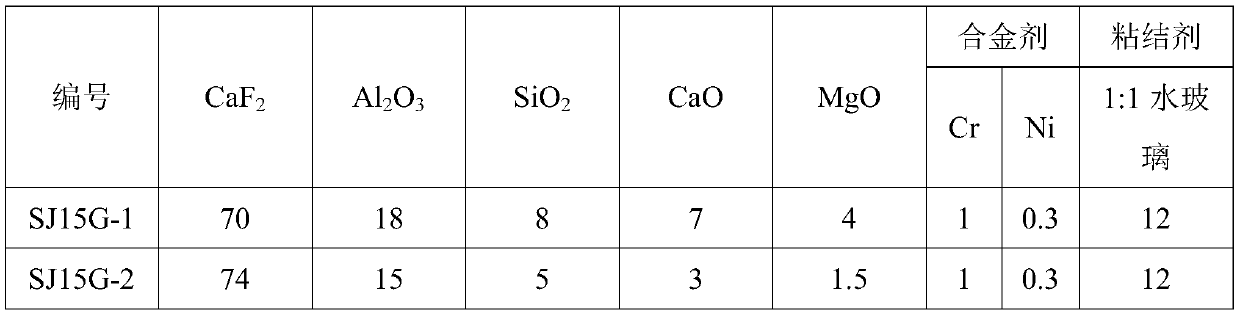

[0018] Specific embodiment one: A kind of high-efficiency 309Nb single-layer strip surfacing welding sintered flux used in conjunction with the EQ309LNb welding strip of this embodiment is characterized in that it is composed of: CaF by weight 2 70-80 parts, Al 2 o 3 15-20 parts, SiO 2 4-10 parts, 2-8 parts of CaO, 1-5 parts of MgO, 1-2 parts of alloying agent and 10-15 parts of binder;

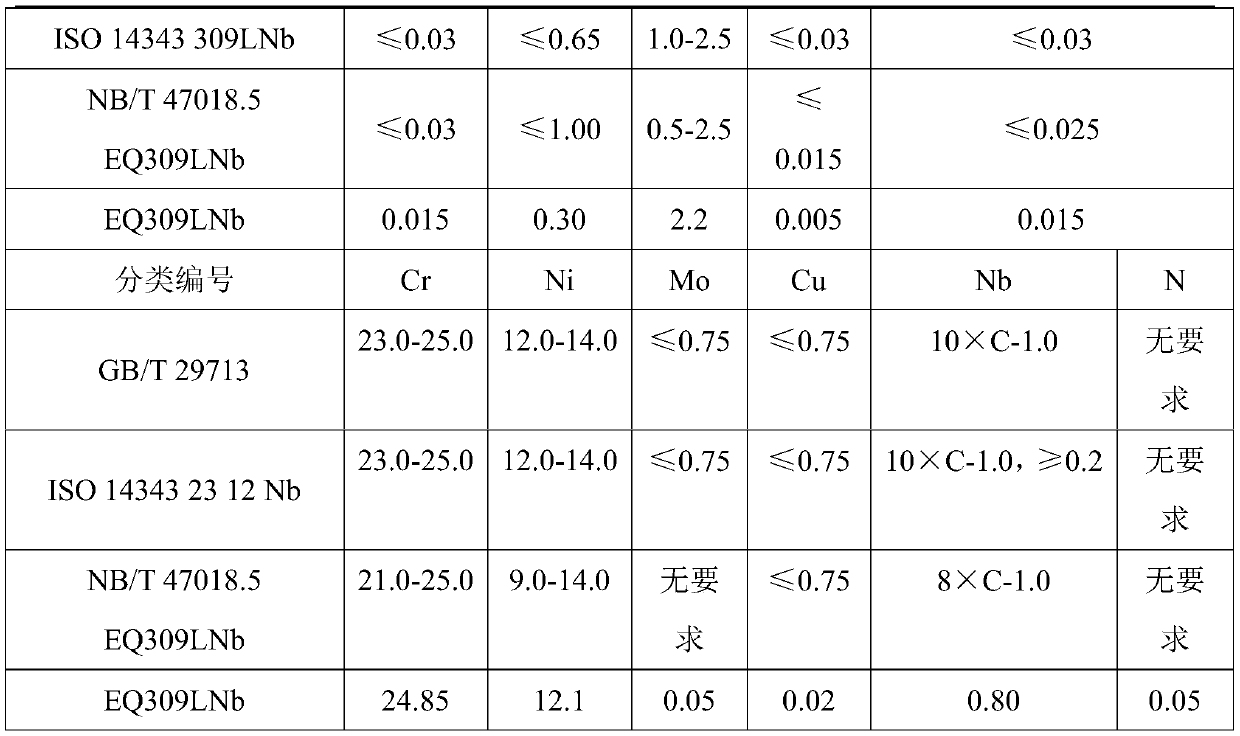

[0019] The composition of the EQ309LNb welding strip in mass percentage is: C≤0.02%, Si≤0.65%, Mn 1.5-2.5%, Cr 23.0-25.0%, Ni 12.0-13.0%, Nb 0.7-1.0%, Nb ≤0.06%, Cu≤0.20%, S≤0.010%, P≤0.020%, Mo≤0.20, and the rest is Fe.

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the sintered flux is composed of: CaF 2 74~80 parts, Al 2 o 3 18~20 parts, SiO 2 5-8 parts, 3-7 parts of CaO, 1.5-4 parts of MgO, 1.3-2 parts of alloying agent and 12-15 parts of binder. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the sintered flux is composed of: CaF 2 74~77 parts, Al 2 o 3 16~20 parts, SiO 2 5-8 parts, 3-6 parts of CaO, 2-4 parts of MgO, 1.5-2 parts of alloying agent and 12-15 parts of binder. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com