Nepenthes type aluminum scrap recycling treatment process

A technology for recycling and processing nepenthes, which is applied to the improvement of process efficiency, filter screen, grille, etc., can solve the problem of affecting the working efficiency of the aluminum scrap recycling process, increasing the cost input of aluminum scrap recycling, and affecting the screening effect of the screen, etc. problems, to achieve the effect of excellent wear resistance, excellent tensile strength, excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

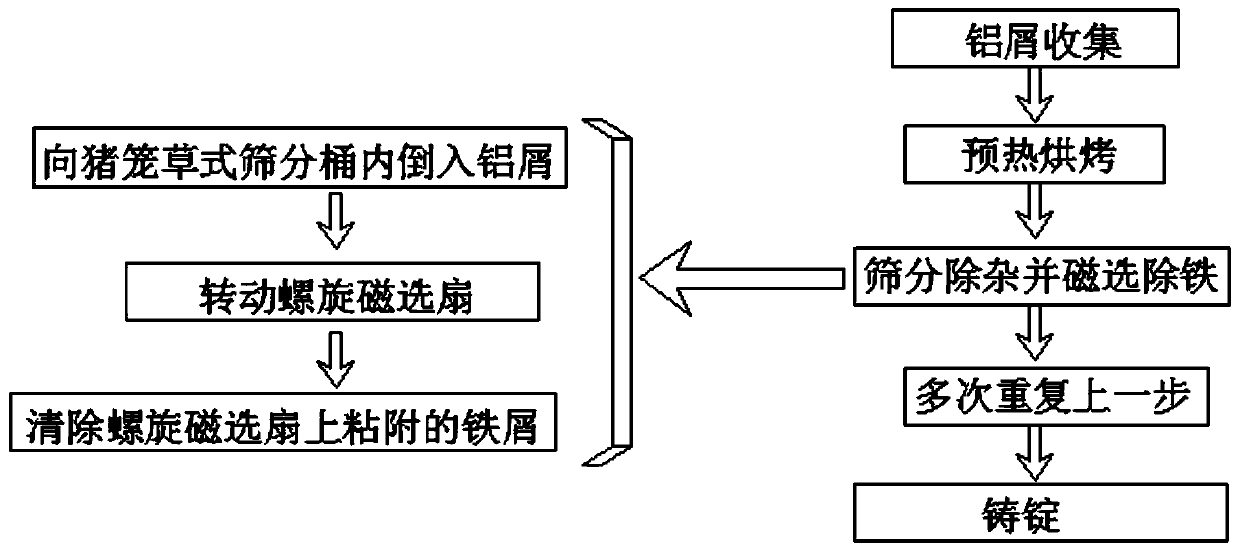

[0051] see figure 1 , a kind of nepenthes type aluminum scrap recycling process, comprises the following steps:

[0052] S1. Collect aluminum shavings produced after aluminum processing in the workshop;

[0053] S2. Preheating and baking. Put the aluminum chips recovered in S1 on the steel plate to heat and bake to remove the oil and moisture on the aluminum chips. The baking temperature is controlled between 280°C. If the temperature is too high, not only the heat loss is large, Moreover, it will cause strong oxidation of aluminum chips, and too low temperature will lead to prolonged baking time, which will affect the efficiency of recycling aluminum chips;

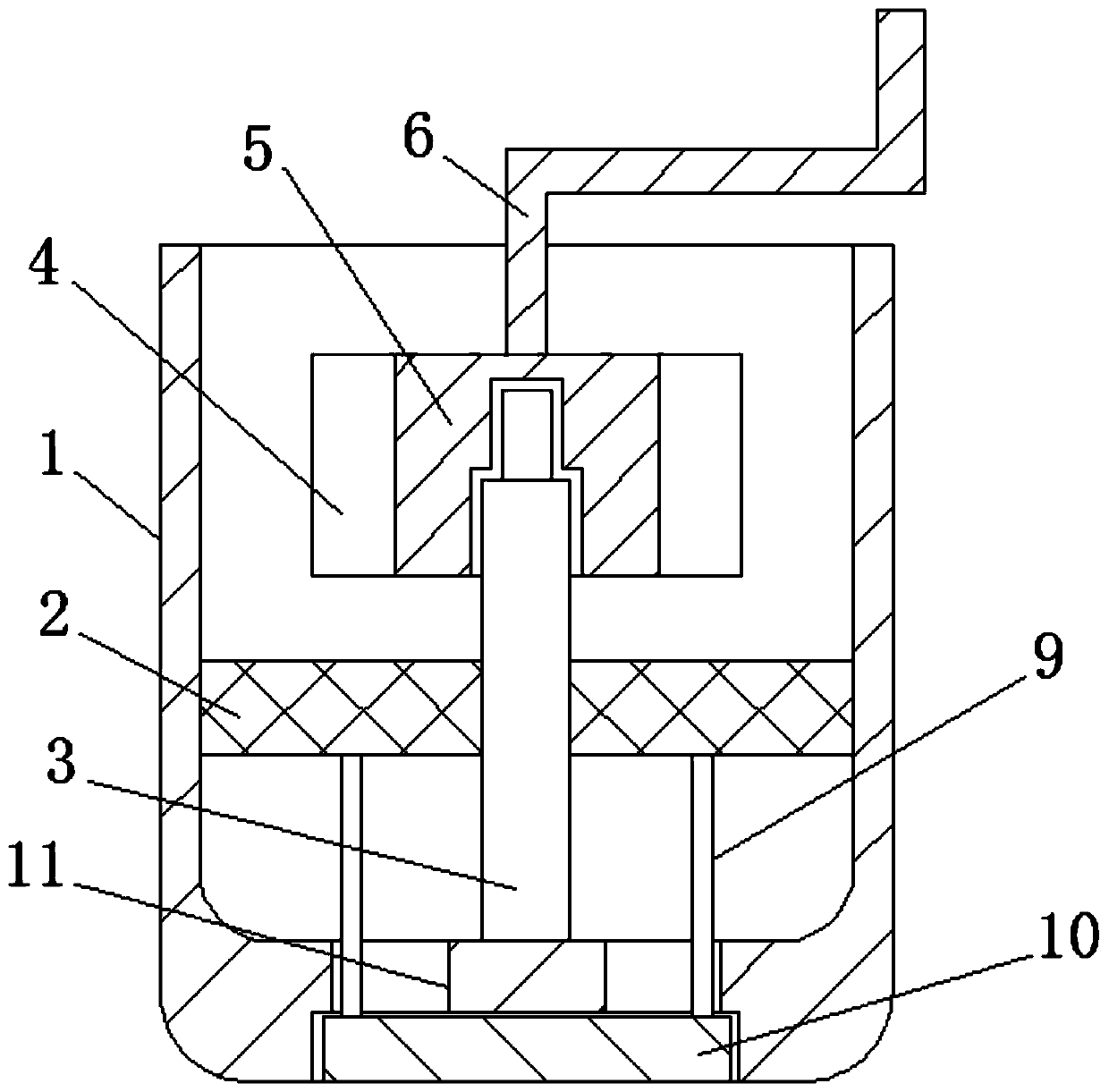

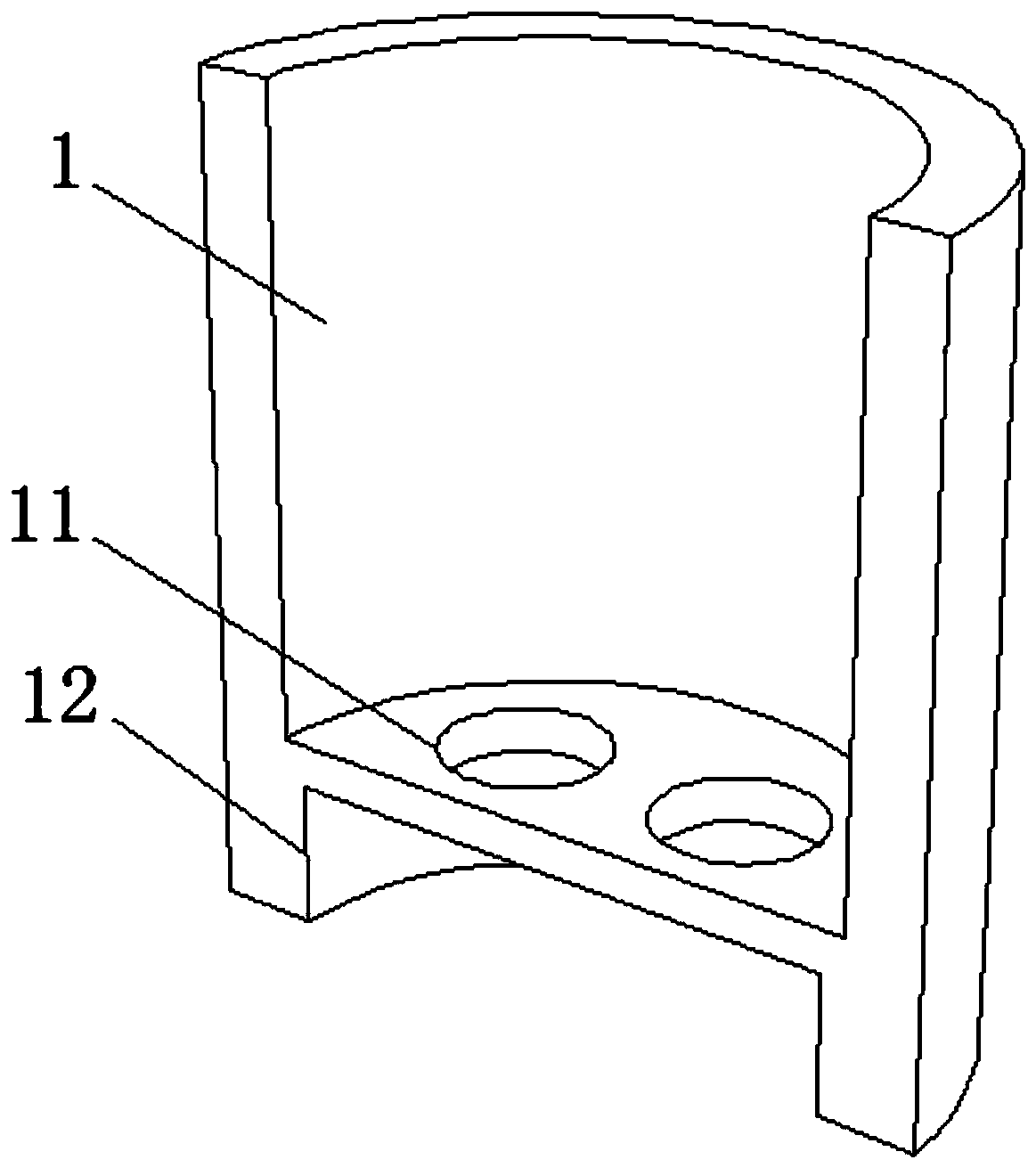

[0054] S3. Screening to remove impurities and magnetic separation to remove iron. Pour the cooled aluminum scraps into a pitcher-type sieving bucket for screening to remove impurities such as sediment and oxidized powder, so the iron scraps can be removed. ; The specific operation is:

[0055] Step 1: Pour an appropri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com