Compound nanofiltration membrane with vinylon water-soluble threads as (sacrifice) middle layer and preparing method thereof

A composite nanofiltration membrane and intermediate layer technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of cumbersome operation process and complicated preparation of nanoparticles, and achieve the increase of pure water permeation flux, The effect of improving permeability and reducing water transport resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

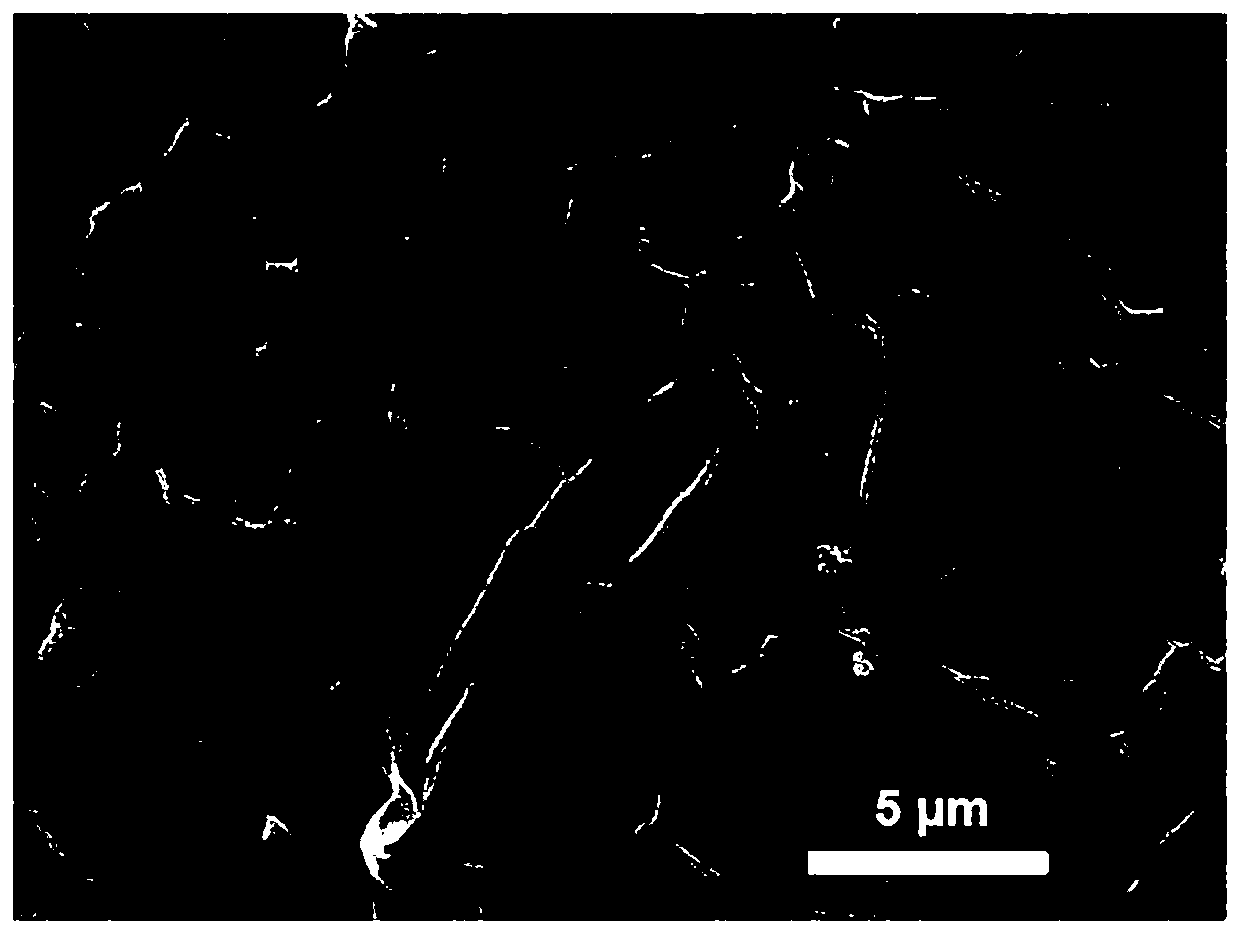

Image

Examples

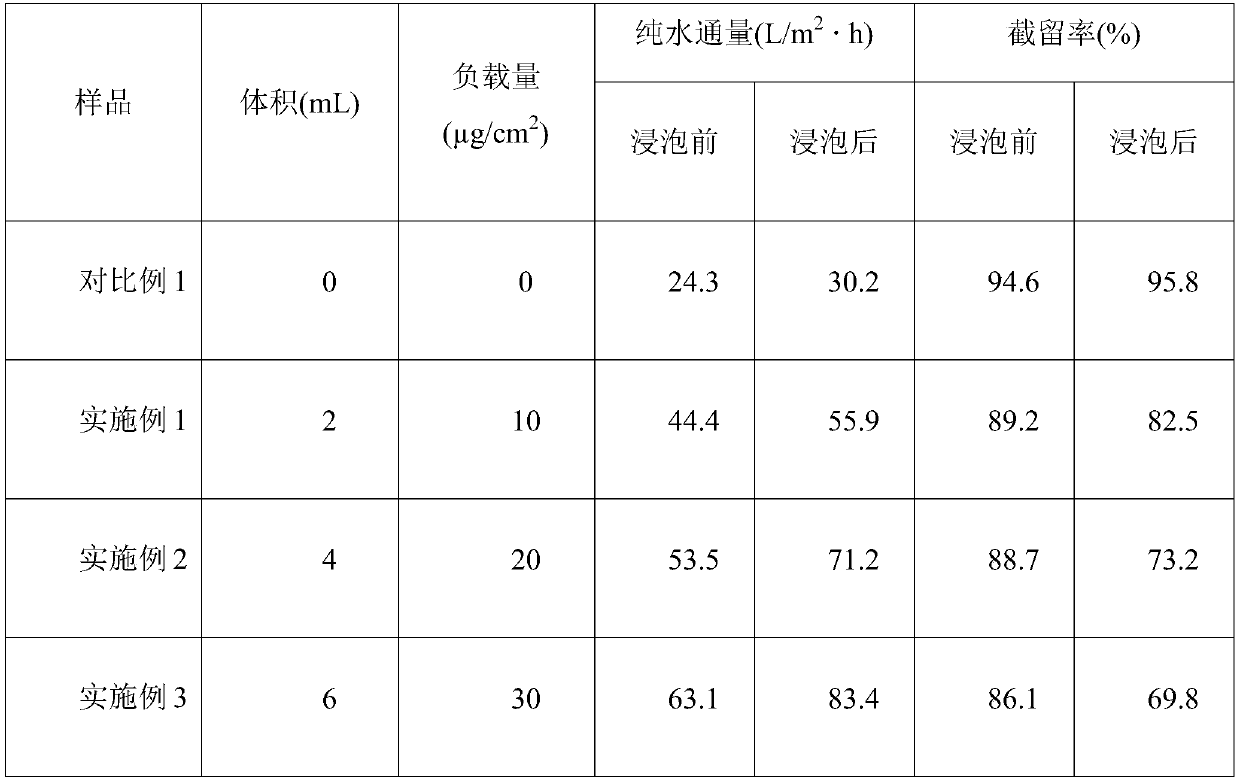

Embodiment 1

[0036] (1) Stir the vinylon aqueous solution with a concentration of 0.0625g / L in a high-speed dispersion mixer at 13000rpm for 1h, and stir for 30min under an ultrasonic cell pulverizer to obtain a uniformly dispersed solution;

[0037] (2) sandwich the membrane between the filter element and the filter cup of the suction filtration device, take 2mL of the solution containing vinylon hydrolyzate, and filter it onto the polysulfone base membrane to form a vinylon hydrolyzate layer;

[0038] (3) Dissolve piperazine with a concentration of 0.3w / v% in deionized water, pour it into a filter cup, soak for 5 minutes, and then apply pressure and filter to remove the aqueous phase monomer solution until there are no obvious drops of water on the surface;

[0039] (4) Dissolve trimesoyl chloride with a concentration of 0.15w / v% in cyclohexane to form an oil phase solution; immerse the film prepared above for interfacial polymerization reaction for 1 minute to obtain a composite membran...

Embodiment 2

[0043] It is basically the same as Example 1, except that the water-soluble line of vinylon filtered by suction is 4mL.

Embodiment 3

[0045] It is basically the same as Example 1, except that the water-soluble line of vinylon filtered by suction is 6mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com