Functional anti-sensitive barrier ink-jet ink and preparation method and application thereof

An inkjet ink, functional technology, applied in the field of daily necessities, can solve the problems of indistinguishable endogenous sensitive type and exogenous sensitive type, inkjet ink cannot be continuously and smoothly ejected, poor targeting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] 1.1

[0075] A functional anti-allergic barrier ink-jet ink, comprising a solvent with a mass ratio of 100:1 and an anti-allergic barrier functional substance, the solvent being a low-polarity grease (hydrogenated polydecene) with a volume ratio of 5:18:2 , a mixture of glucoside (myristyl glucoside), lecithin (hydrogenated lecithin);

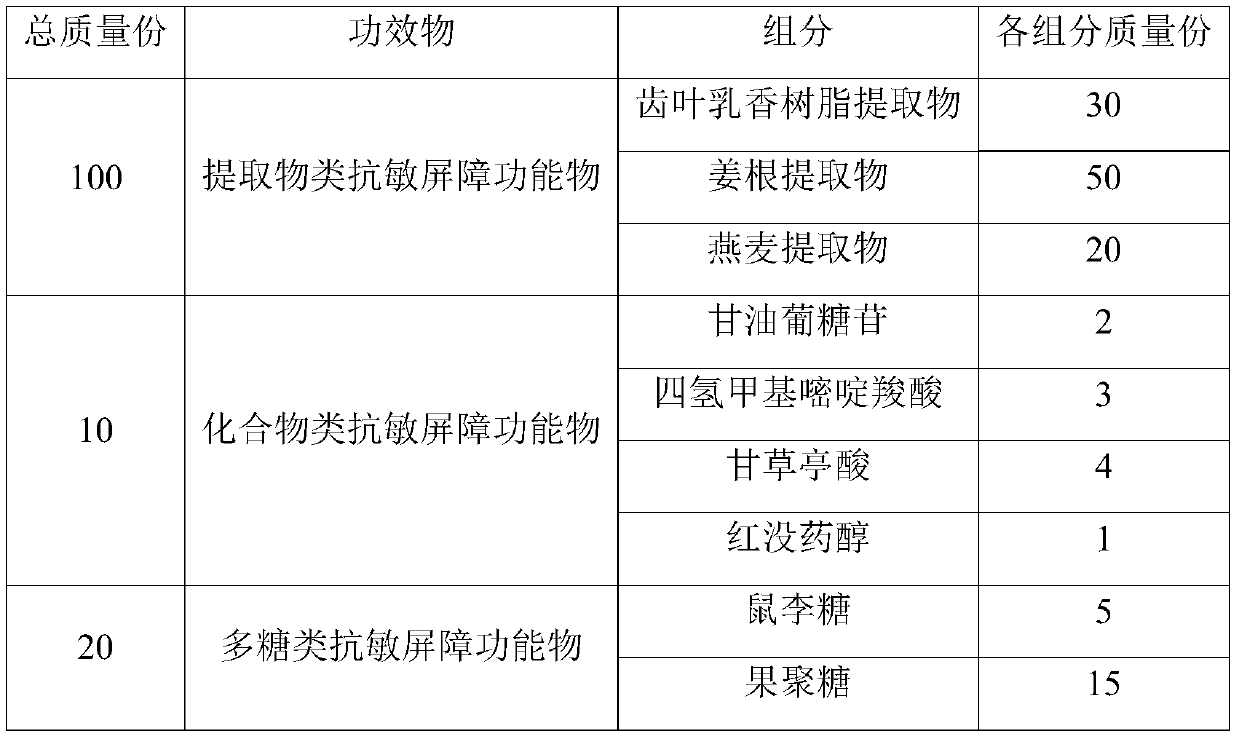

[0076] The composition of the anti-allergic barrier functional substance is shown in the table below:

[0077]

[0078] The functional anti-sensitive barrier inkjet ink is prepared by the following method:

[0079] Step 1, mixing low-polar oil (hydrogenated polydecene) and surfactant glucoside (myristyl glucoside) into the first phase, stirring at room temperature until uniformly mixed;

[0080] Step 2, mixing the anti-allergic barrier function substance and lecithin (hydrogenated lecithin) to form the second phase, and stirring at room temperature until the mixture is uniform;

[0081] Step 3, mix the first phase and the second ph...

Embodiment 2

[0108] In the following embodiments, the inkjet printer can choose a commercially available thermal induction nozzle or piezoelectric nozzle, preferably a piezoelectric nozzle.

[0109] 2.1

[0110] Embodiment 1.1 ink-jet ink is sprayed on dry film by ink-jet printer, and spraying amount is 150g / m 2 , the dry film is a silk non-woven fabric to obtain an anti-allergic barrier mask. The printed mask can dry naturally within 7 minutes (the drying standard is that the mask has almost no liquid feeling after touching).

[0111] 2.2

[0112] Embodiment 1.2 inkjet ink is sprayed on dry film by inkjet printer, and spraying amount is 100g / m 2 , the dry film is a dehydrated mud film to obtain an anti-allergic barrier mask. The printed mask can be dried naturally within 5 minutes.

[0113] 2.3

[0114] Embodiment 1.3 inkjet ink is sprayed on dry film by inkjet printer, and spraying amount is 100g / m 2 , the dry film is a dehydrated mud film to obtain an anti-allergic barrier mask. ...

Embodiment 3

[0125] Various formulations of Example 1 were made into ink-jet inks, placed in different containers, and numbered. When actually customizing the skin care mask, according to the data of the skin tester, the beautician will put the ink bottle matching the applicable number into the inkjet cartridge, set it in different printing areas and different ink cartridges according to the skin test report, and then start the printing function for online Custom face mask printing.

[0126] Specific steps are as follows:

[0127] 1) Detect the skin condition and face shape through the skin detection device installed in the beauty place,

[0128] 2) Match the corresponding ink formula;

[0129] 3) Start the printing function, set the printing position and ink cartridge, and print on the film cloth;

[0130] 4) Then punch the membrane cloth into the specified shape.

[0131] The specific application examples are only excerpts of typical examples. Using a commercially available TAOMEI sk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com