Horizontal push and pulldown type rice seedling transplanting mechanism

A technology of flat push-down and seedling boards, which is applied in the direction of transplanting machinery, planting methods, cultivation, etc., can solve the problems of empty planting of seedlings, vacancy of seedlings delivered by rice transplanters, etc., achieve uniform planting density, ensure production, and improve planting resistance. lodging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a flat push down pull-type rice transplanting mechanism, including a frame 1, a seedling release box 2, an upper seedling clamp 3, a phosphate fertilizer tank 4, a seedling drop tube 5, a lower seedling clamp 6, and a power assembly structure 7;

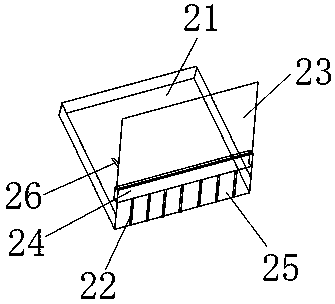

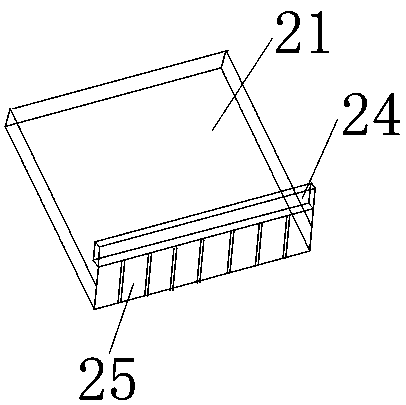

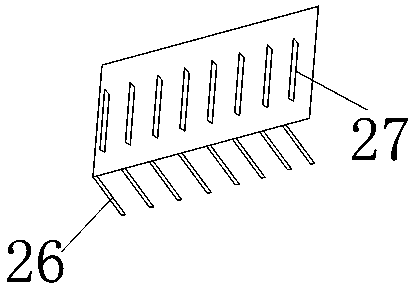

[0030] The seedling-releasing box 2 is installed on the frame 1, and the seedling-releasing box 2 includes a seedling-releasing plate 21, a barred seedling-blocking plate 22 and a barred seedling-pushing plate 23. For seedlings, the lower part of the seedling blocking plate 22 is fixedly connected with the seedling release plate 21, the top of the seedling blocking plate 22 is equipped with a slide rail 24, and the seedling blocking plate 22 is provided with N grids 25, N>1 The bottom of the seedling pushing plate 23 with the grid is movably connected with the slide rail 24 of the seedling blocking plate 22 with the grid, and the seedling pushing plate 23 with the grid can slide left and right along the slide rail...

Embodiment 2

[0037] Embodiment two: a kind of flat pushing down dragging type rice transplanting mechanism, its basic structure is identical with embodiment one, difference is: the screw mandrel 31 in the top seedling clamp 3 is replaced with rack 31 '. That is, the upper seedling clamp 3' includes a rack 31', an upper fixed single tong 32, an upper movable single tong 33, and a flywheel 34'. The upper fixed single tong 32 and the upper movable single tong 33 pass through the "7" type track structure 35 connection, the upper fixed single pliers 32 and the upper movable single pliers 33 are installed on the rack 31 ', and the two sides of the rack 31 ' mesh with the left and right flywheels 34 ' respectively, and the front end of the upper fixed single pliers 32 is provided with a movable single pliers facing the upper part. The inner bending hook 37 of the pliers, the two ends of the rack 31' are movably connected with the frame 1, the brake line V105 is connected to the flywheel 34' on the...

Embodiment 3

[0038] Embodiment 3: A kind of flat pushing and pulling down rice transplanting mechanism, including frame 1 ,, , Seedling box 2 ,, , seedling clamp 3 ,, , Powertrain structure 7 ,, ;

[0039] The seedling box 2 ,, Through screw 31 ,, mounted on frame 1 ,, Upper, screw mandrel 31 ,, Both sides are equipped with flywheel 34 respectively ,, , brake line Ⅴ105 ,, Connecting screw 31 ,, Flywheel on one side 34 ,, , brake line Ⅴ105 ,, Can control screw 31 ,, Flywheel on one side 34 ,, Turn one step clockwise; brake line Ⅵ106 ,, Connect the flywheel 34 on the other side of the screw mandrel ,, , brake line Ⅵ106 ,, Can control screw 31 ,, Flywheel on the other side 34 ,, Turn counterclockwise one step, screw 31 ,, Can drive seedling box 2 ,, Move left and right as a whole; Seedling box 2 ,, Including seedling board 21 ,, , there are fence seedling board 22 ,, And push seedling plate with grid 23 ,, , put the seedling plate 21 ,, Used to place the seedlings pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com