Ceramic dielectric filled waveguide filter

A waveguide filter and ceramic dielectric technology, which is applied in the field of dielectric filled waveguide filters and ceramic dielectric filled waveguide filters, can solve the problems of more zero requirements, the inability to realize cross-coupling of cross resonators, and inability to realize coupling transmission zero, etc. Achieve the effect of overall stability and reliability, simple and novel structure, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

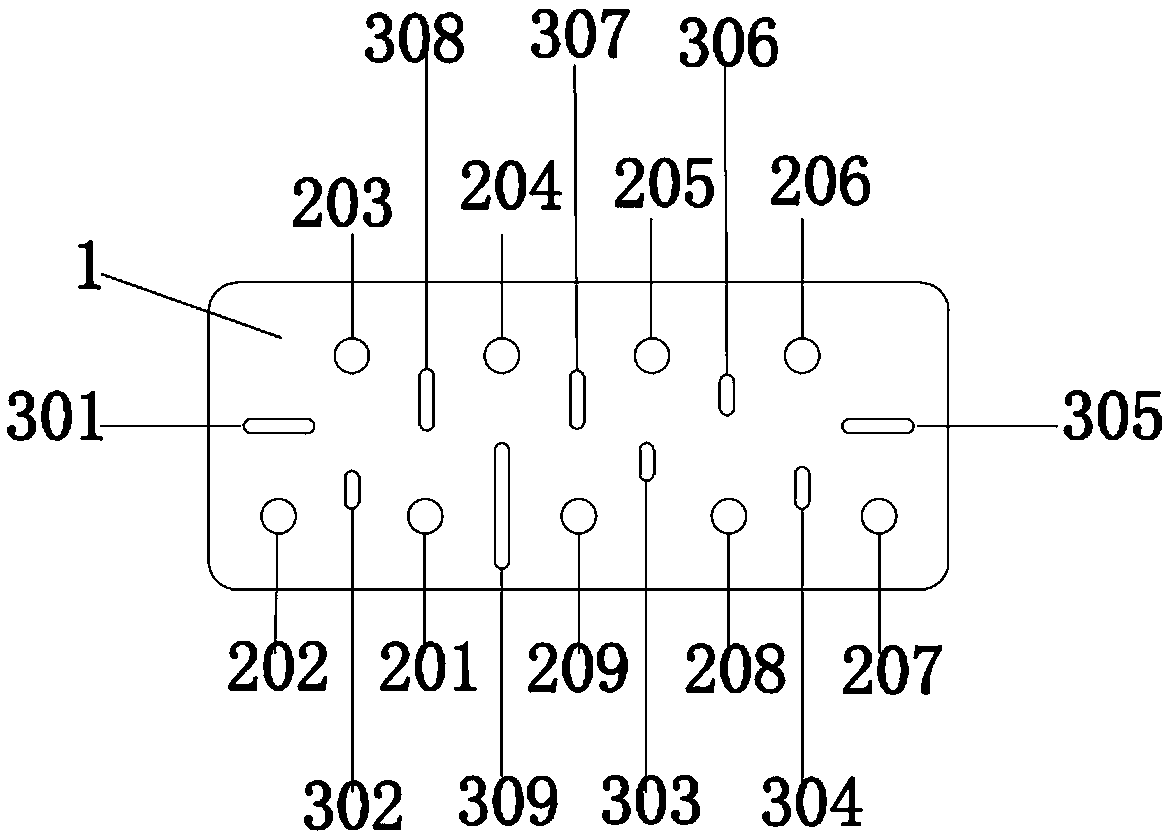

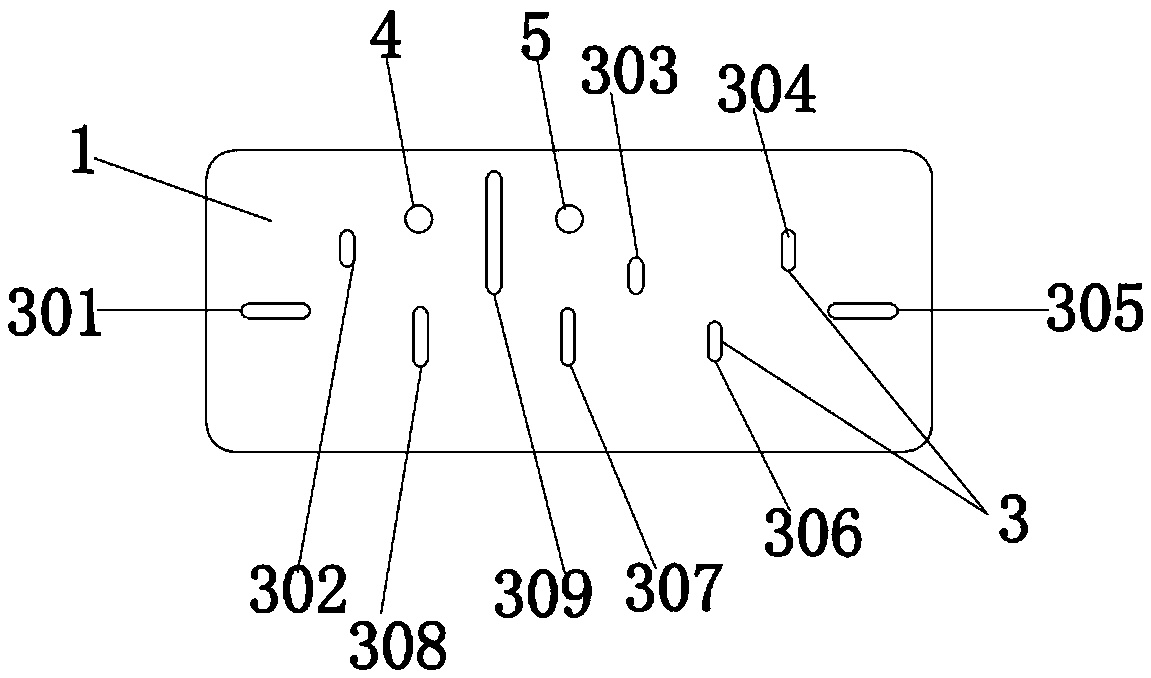

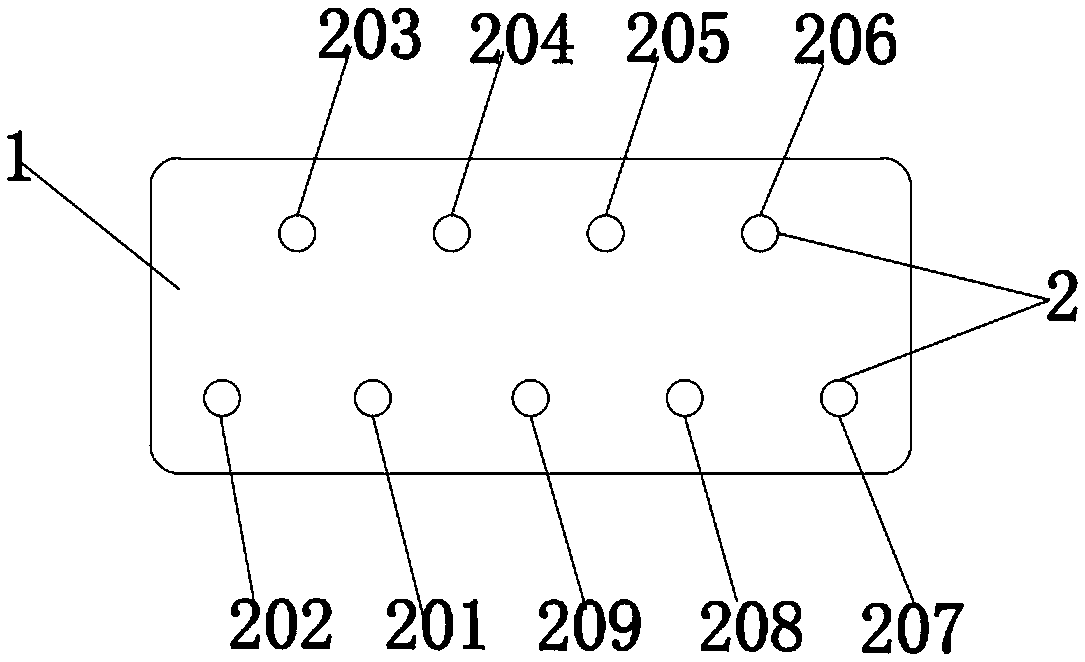

[0035] A ceramic dielectric filled waveguide filter, the waveguide filter adopts a topological structure of resonant cavities dislocation, and resonant cavities 2 arranged in dislocation are easy to realize multiple cross-coupling structures; the waveguide filter includes a ceramic dielectric block 1, a resonant cavity group, The groove 3, the input port 4, the output port 5, and the resonant cavity group are set on the ceramic dielectric block 1. The resonant cavity group includes a plurality of resonant cavities 2 arranged in parallel on the upper and lower layers and arranged in a dislocation. The resonant cavity 2 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com