Arc extinguishing device based on segmented insulator

A segmented insulator and arc extinguishing device technology, which is applied to high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve the problem of arc segmentation under unfavorable working conditions, threatening the safety of the traction power supply system, and successfully extinguishing the arc at the arc angle To improve monitoring efficiency and accuracy, reduce erosion and thermal effects, and improve arc extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

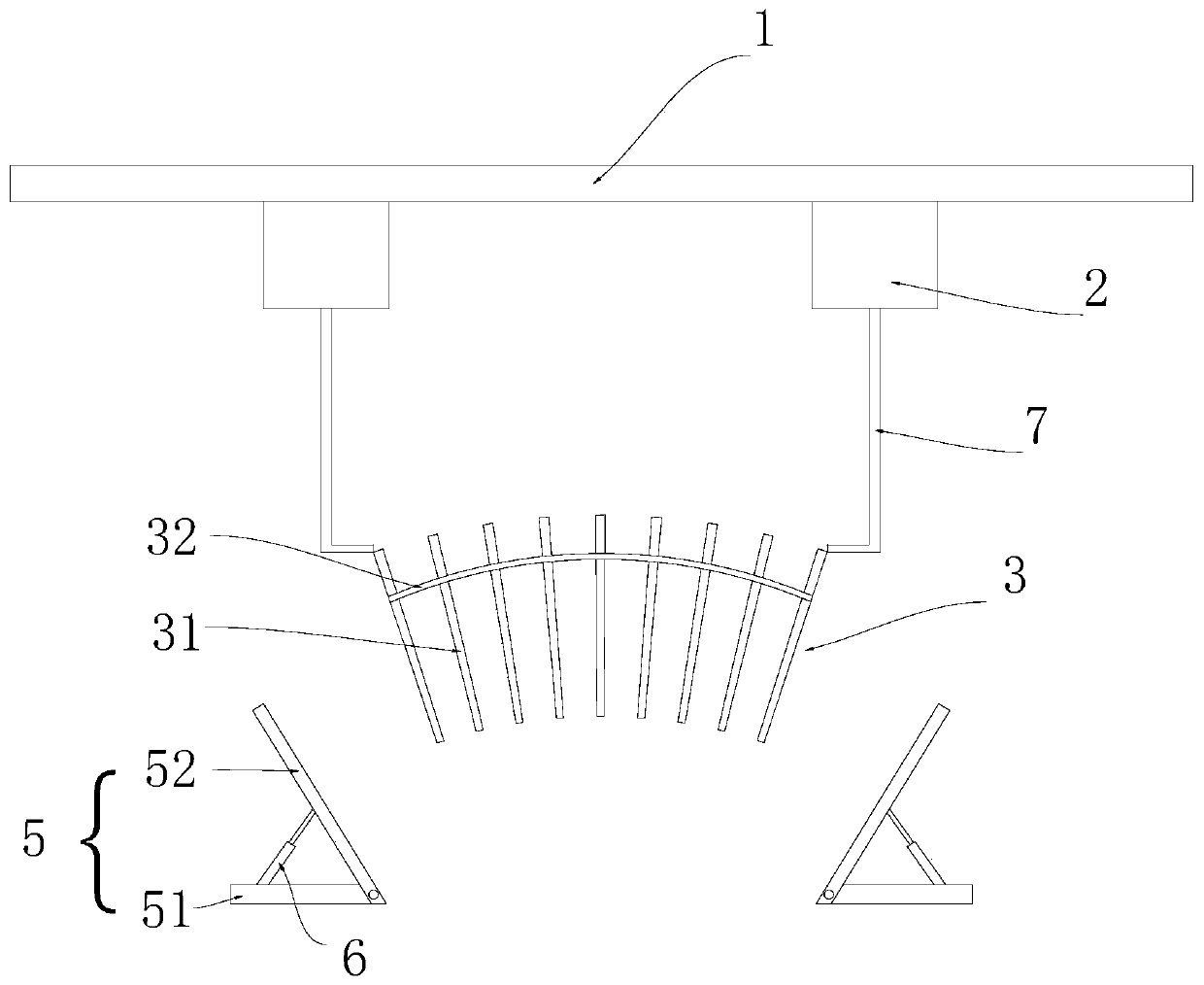

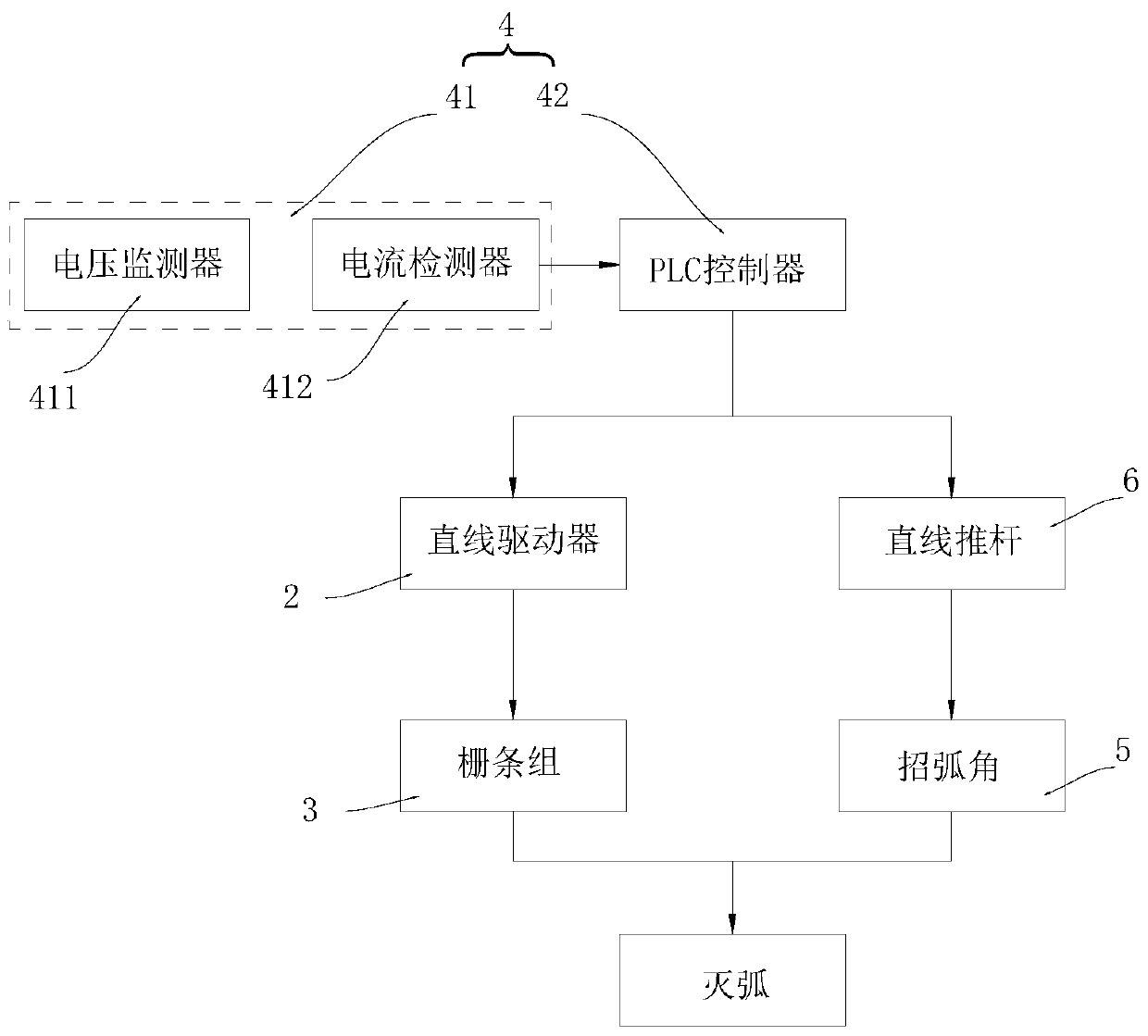

[0024] see Figure 1 to Figure 2 , the present invention includes a suspension cable 1 and two sets of linear actuators 2 arranged on the suspension cable 1 and slidingly connected with the suspension cable 1. The operator can adjust the relative position of the linear actuator 2 and the suspension cable 1 by sliding the linear actuator 2. Between the output ends of the two sets of linear drivers 2 there is a grid bar group 3 for arc extinguishing, and between the linear driver 2 and the grid bar group 3 there is an adjustment suspension wire 7 for connection. Both sides of the bottom end of the grid bar group 3 are provided with an arc angle 5. The grid bar group 3 is composed of a plurality of arc extinguishing grid bars 31 arranged at the output end of the linear driver 2. The shape of the arc extinguishing grid bars 31 is cylindrical and the arc extinguishing grid The material used in bar 31 is high temperature resistant and anti-ablation material. The arc extinguishing g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com