Genetic algorithm-based elevator landing door multi-objective optimization design method

A multi-objective optimization and genetic algorithm technology, applied in the field of elevator landing door structure design, can solve problems such as difficulty in optimizing design parameter combinations, inability to meet production requirements, and difficulty in ensuring optimal parameters, so as to reduce blindness and improve Design efficiency, the effect of improving the safety and reliability of the landing door

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

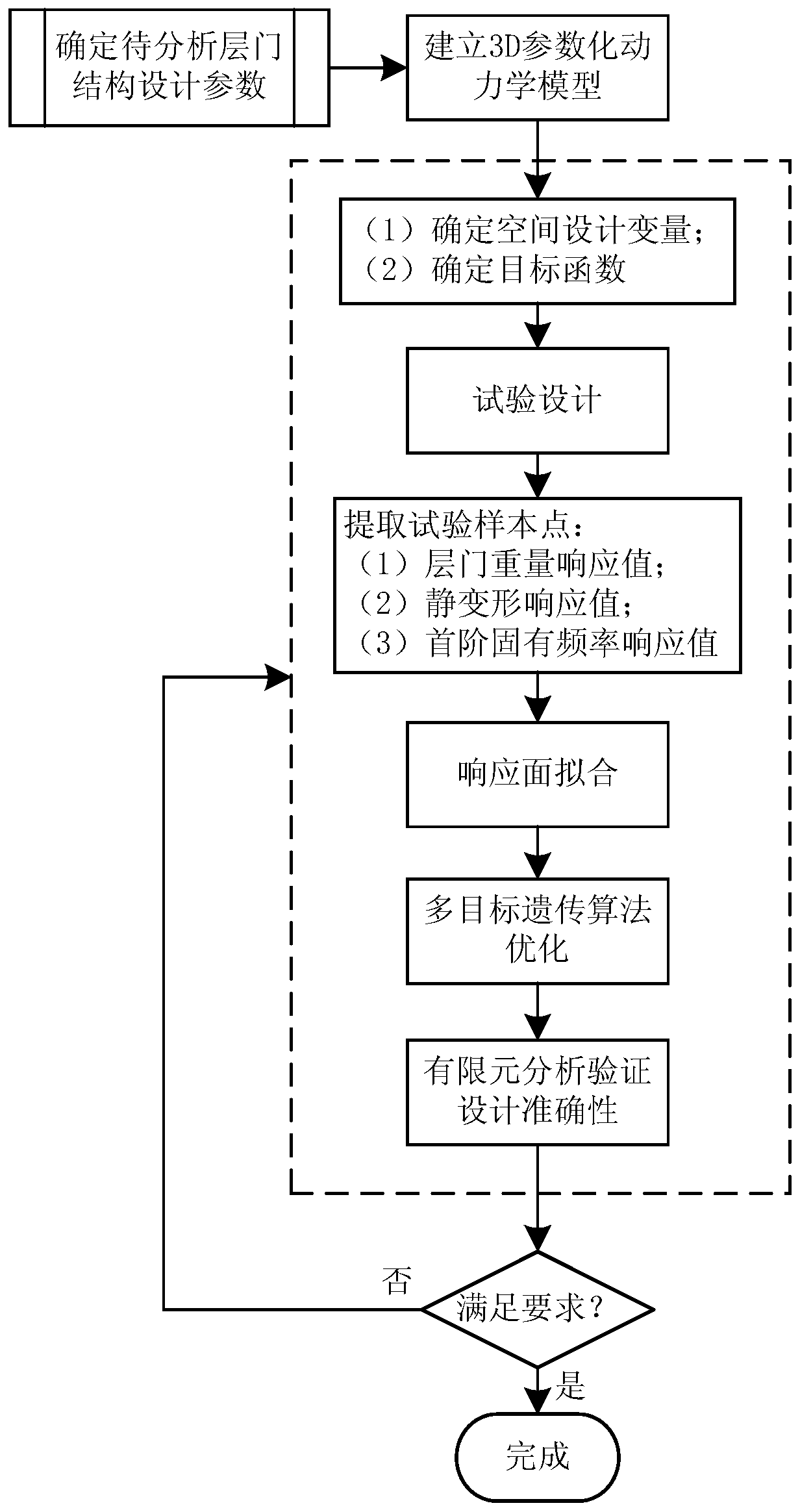

[0027] Such as figure 1 with figure 2 Shown, a kind of elevator floor door multi-objective optimal design method based on genetic algorithm of the present invention comprises the following steps:

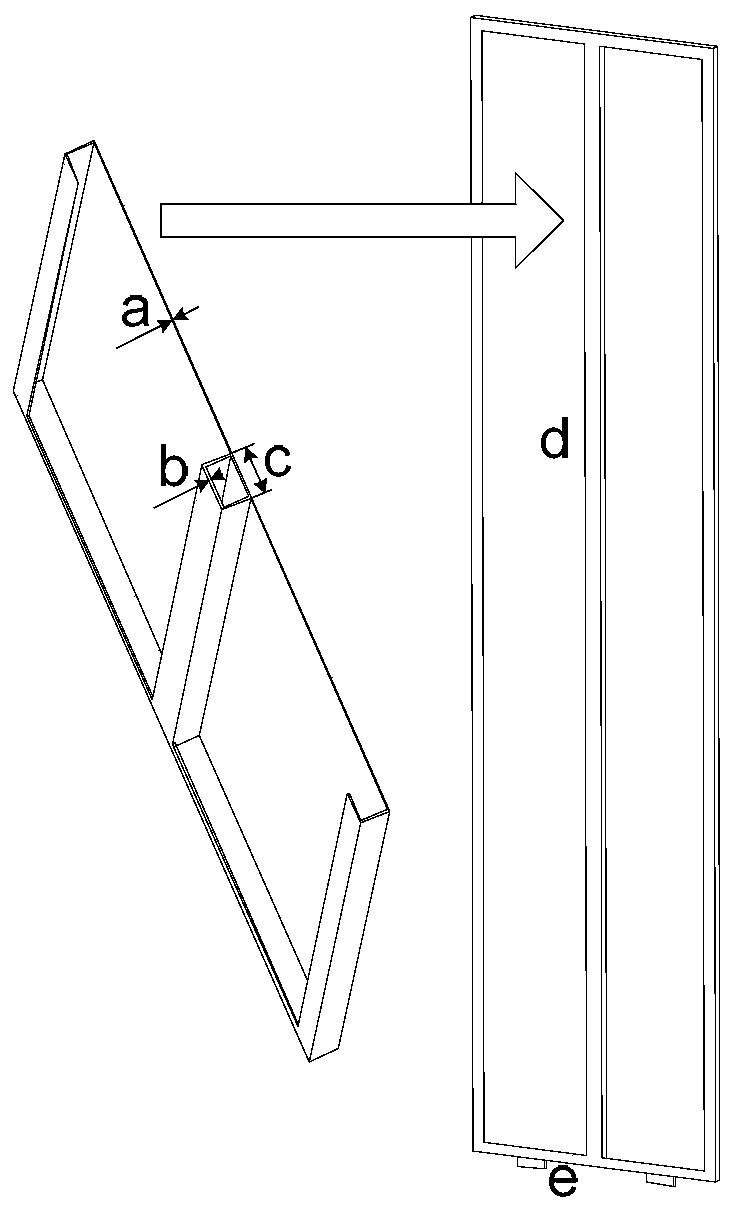

[0028] 1. Determine the structural design parameters of the elevator landing door to be analyzed; this parameter includes the thickness of the door leaf plate a, the thickness of the rib plate b, the width c of the rib plate, the number of ribs d, and the minimum meshing depth e allowed by the guide device or the retaining device. The above parameters have a great influence on the structural performance of the landing door. TSG T7007——2016 "Elevator Type Test Rules" stipulates that the above parameters are the main parameters of the landing door. If the above parameters change, the type test should be carried out again, so the present invention sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com