Steel pipe concrete column-precast concrete superposed beam assembly type building connection node

A technology of concrete-filled steel tube columns and prefabricated concrete, which is applied in the direction of construction and building construction, and can solve problems such as unfavorable prefabricated construction, influence on the strength of joint areas, and difficulty in ensuring quality, so as to improve installation and construction efficiency, and improve production and construction efficiency , The effect of reducing the amount of construction work and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

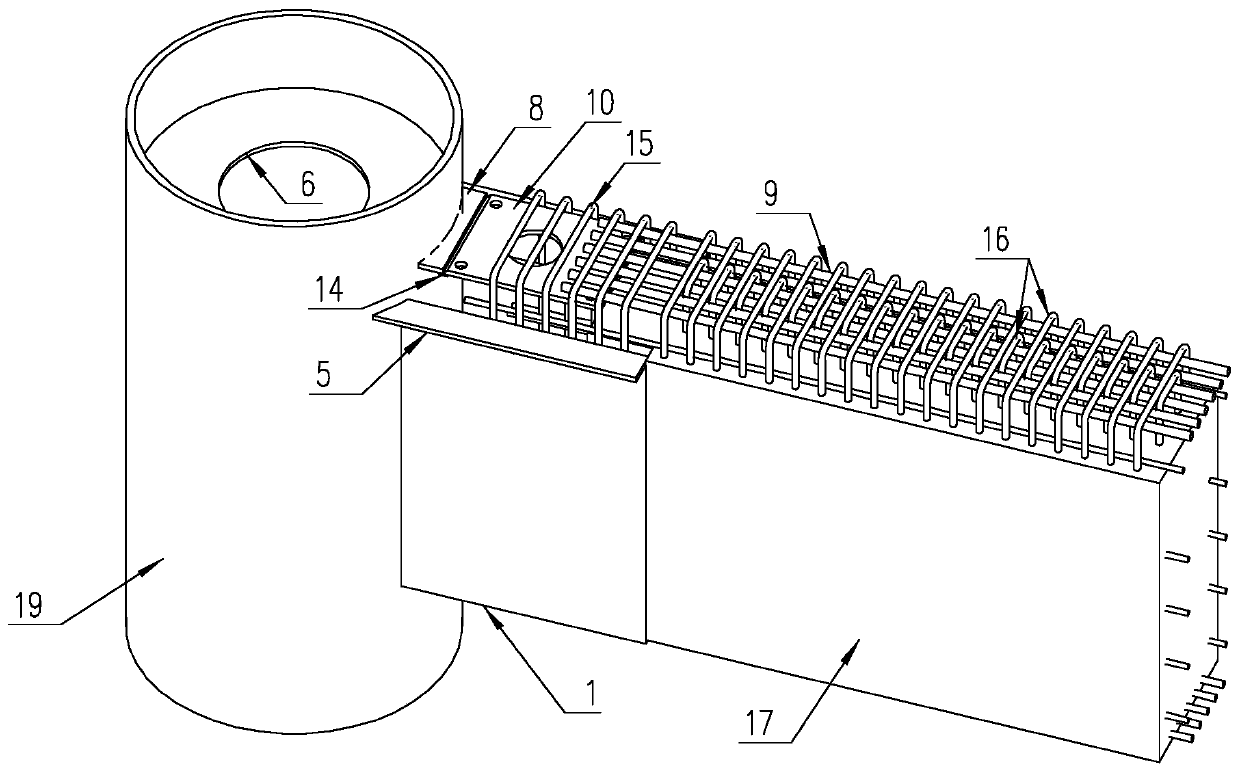

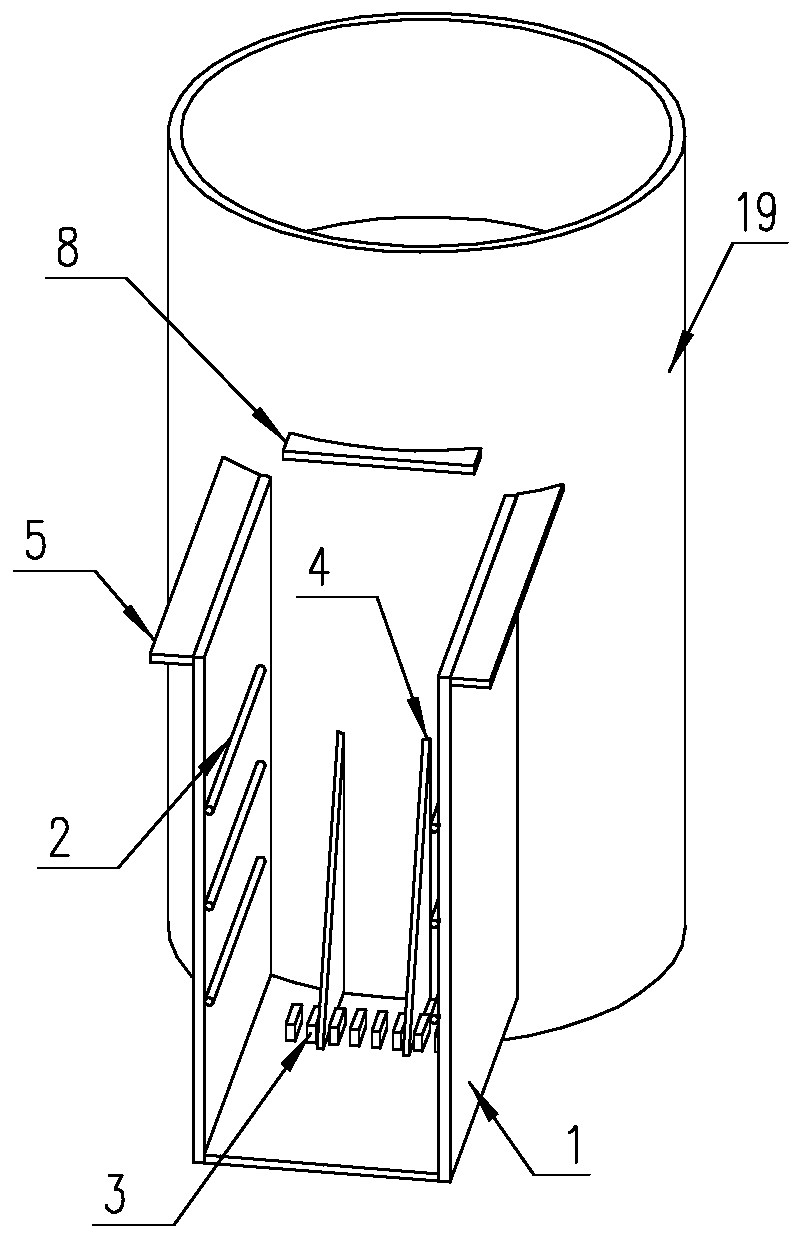

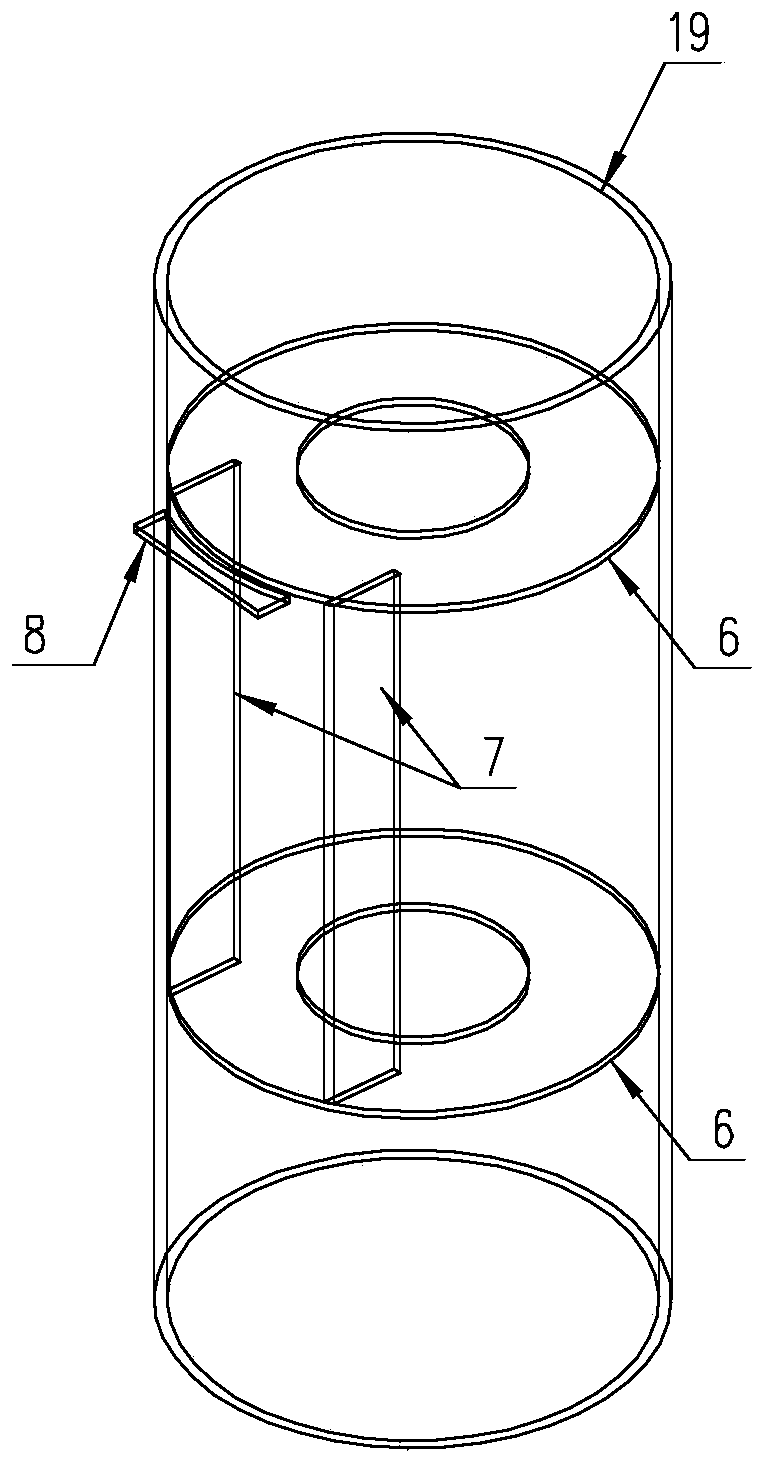

[0037] The prefabricated building connection node of the steel pipe concrete column-prefabricated concrete composite beam of the present invention is as follows figure 1 As shown in Figure 7, it includes concrete-filled steel tube columns and prefabricated concrete composite beams 17. U-shaped steel channels 1 and pre-welded outer ring steel plates 8 are welded on the outer wall of steel tube concrete-filled columns. 1, the U-shaped steel channel 1 has a bottom plate and a side plate, the bottom plate is provided with a bottom steel buckle device 3, and the top of the side plate has an outwardly turned upper flange 5; the precast concrete composite beam 17 is inserted into the U-shaped steel In the groove 1, the bottom of the precast concrete composite beam 17 is clamped with the bottom steel buckle device 3, the top is welded with the pre-welded outer ring steel plate 8, and the area where the precast concrete composite beam 17 is inserted into the U-shaped steel groove 1 For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com