Multi-point floating incremental launching construction system of large-span steel truss girder bridge

A steel truss bridge and jacking construction technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of unspecified multi-point floating support erection, etc., and achieve simple structure, adjustable height, and guaranteed The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

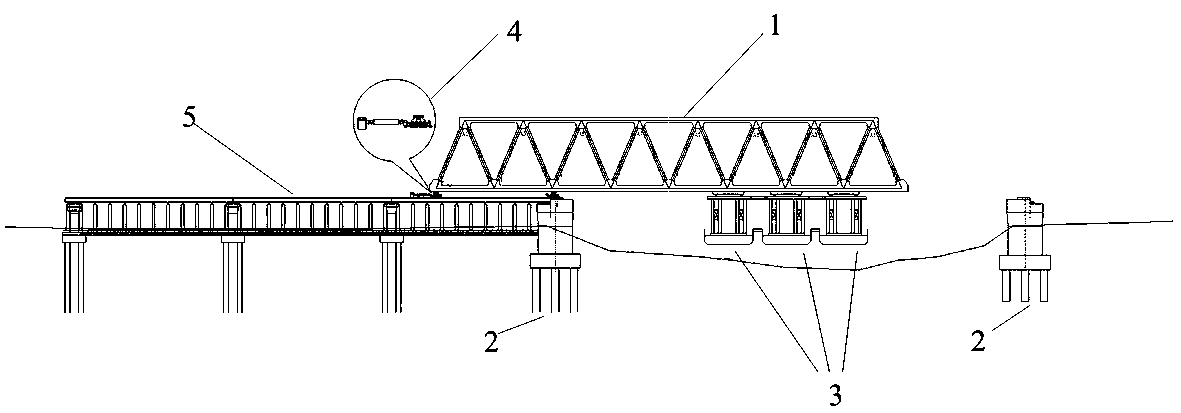

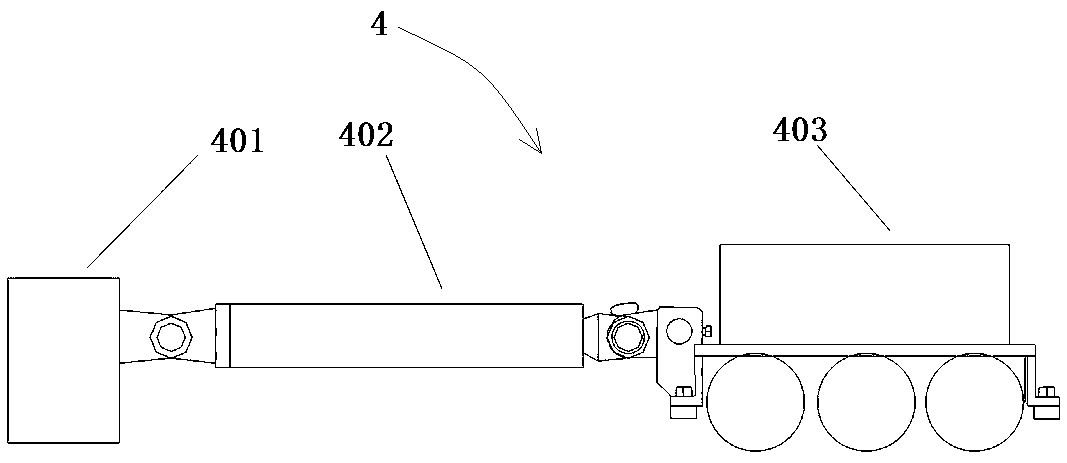

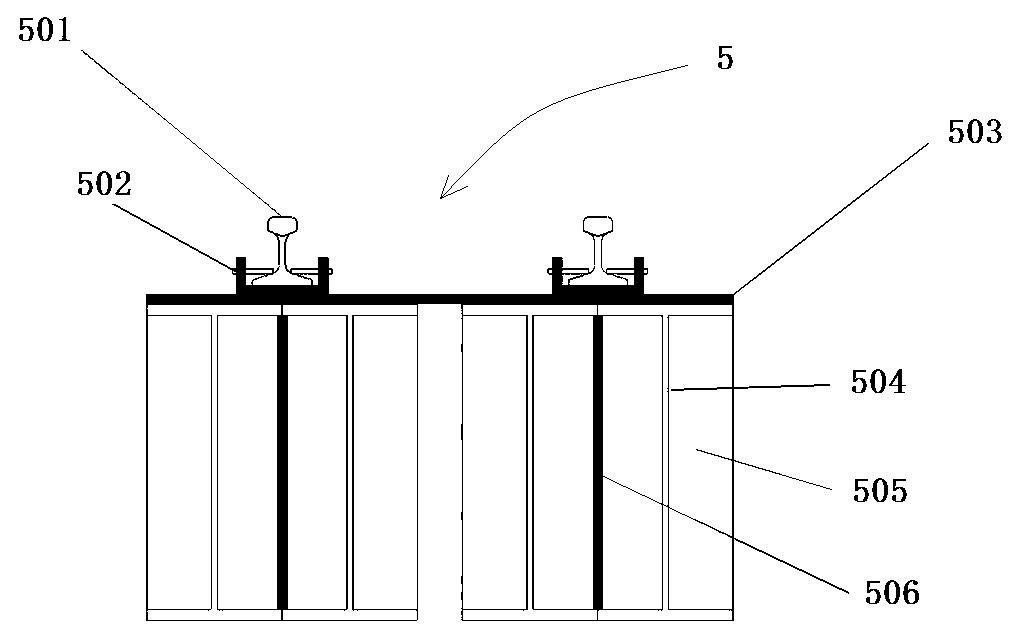

[0024] Example: such as Figure 1-5 As shown, this embodiment specifically relates to a multi-point floating support construction system for a long-span steel truss bridge. The construction system is used to push the steel truss bridge 1 onto the corresponding two piers 2, mainly including Supporting device 3, sliding track 5 and synchronous jacking system 4, this floating supporting device 3 is arranged on the water surface between two bridge piers 2 and supports the front side bottom of steel truss bridge 1; Meanwhile, sliding track 5 is arranged along the longitudinal bridge direction to the pier 2 at the origin of the steel truss bridge 1, and the synchronous pushing system 4 is arranged on the sliding track 5 and supports the pushing forward of the steel truss bridge 1.

[0025] Such as figure 1 As shown, there is a certain distance between the two bridge piers 2, and the distance between the two is the length of the steel truss bridge 1, and the steel truss bridge 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com