Titanium-aluminum-carbon material allowing underwater etching, preparation method thereof, and preparation method of organ-shaped material

A titanium-aluminum-carbon, raw material technology, applied in the field of MAX phase material preparation, can solve the problems of environmental and human injury, and should not be used in large quantities, and achieve the effect of shortening the reaction time, speeding up the process, and avoiding the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Specifically, the preparation method of the titanium-aluminum-carbon material that can be etched in water of the present invention comprises the following steps:

[0034] In the first step, the raw materials used are Ti powder (99.9%), Al powder (98.9%), TiC powder (99.9%), and the powders of A-site doping elements are Si powder, Ga powder, Ge powder, In powder and Sn powder One or more of them; pure Ga powder (99.9%), In powder (99.9%) and Sn powder (99.9%) are preferred. The raw materials are all reagents from Aladdin Company. TiC as the preparation of Ti 3 AlC 2 It is a low-temperature additive for materials, which will reduce the temperature of phase formation; Al powder and powder of A-site doping elements are used to synthesize low-temperature soluble aluminum alloy raw materials, and must be kept at low temperature during sintering to generate soluble aluminum alloys. Instead of pure Al atomic layer.

[0035] In the second step, the Ti powder, Al powder, and ...

Embodiment 1

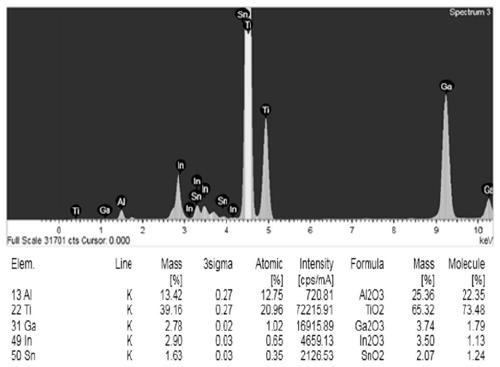

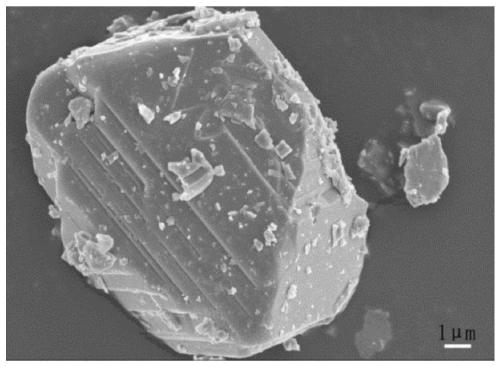

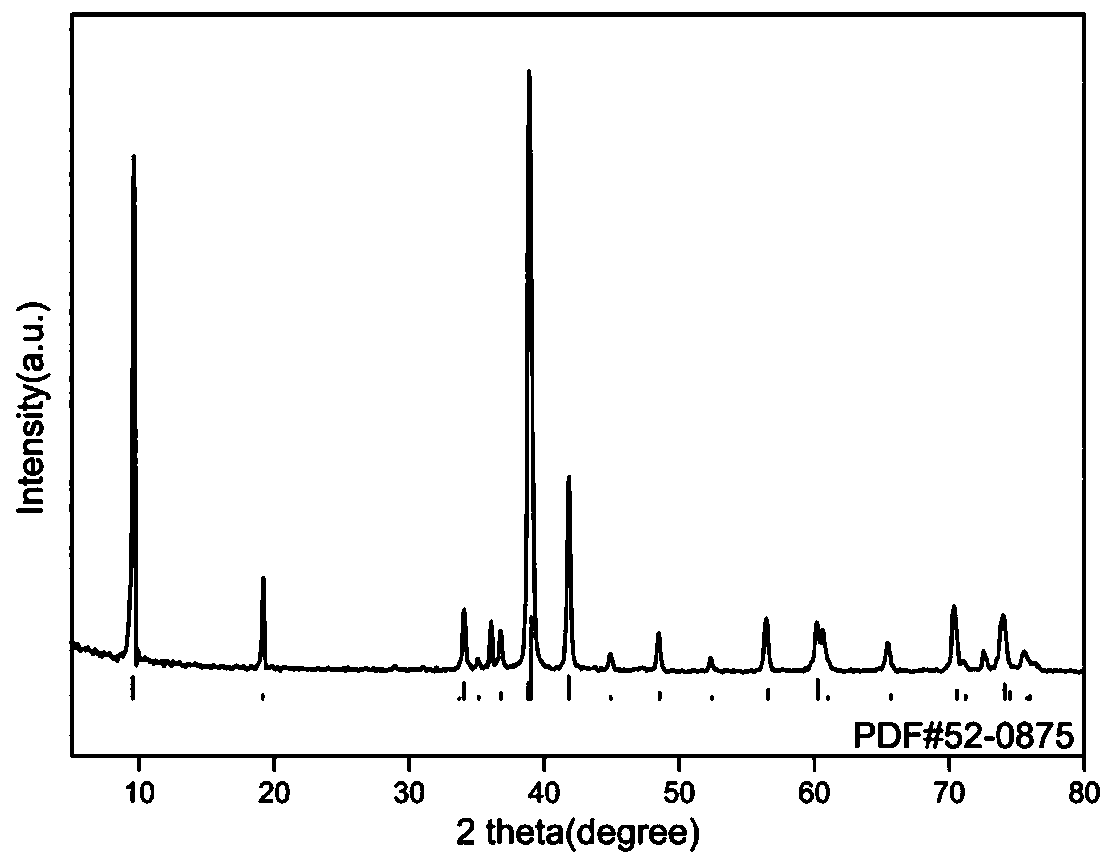

[0041] In the glove box, grind Ti powder, Al powder, TiC powder, Ga powder, In powder and Sn powder to obtain a uniformly mixed raw material. The molar ratio of Ti powder, Al powder and TiC powder is 3:1.2:2, with Based on the total mass of Al powder and A-site doping element powder, the percentage content of each component is: Al powder 90%, Sn powder 6%, Ga powder 2%, In powder 2%; graphite in spark plasma sintering furnace The inside of the mold is lined with a layer of graphite paper. Take 5g of the raw material mixed uniformly with an agate mortar and ball mill in the glove box and put it into the graphite mold. In the spark plasma sintering furnace, under vacuum conditions, apply an axial pressure of 10MPa. The heating rate is 100°C / min, hold at 700°C for 5 minutes, and hold at 1200°C for 5 minutes to obtain the required titanium-aluminum-carbon ceramic block that can be etched in water, and put the obtained ceramic block into Al 2 o 3 Add an appropriate amount of agate...

Embodiment 2

[0043] In the glove box, Ti powder, Al powder, TiC powder, Ga powder, In powder and Sn powder are ground to obtain a uniformly mixed raw material, and the molar ratio of Ti powder, Al powder and TiC powder is 3:1.4:2, with Based on the total mass of Al powder and A-site doping element powder, the percentage content of each component is: Al powder 70%, Sn powder 10%, Ga powder 15%, In powder 5%; graphite in spark plasma sintering furnace The inside of the mold is lined with a layer of graphite paper. Take 5g of the raw material mixed uniformly with an agate mortar and ball mill in the glove box and put it into the graphite mold. In the spark plasma sintering furnace, under vacuum conditions, apply an axial pressure of 30MPa. The heating rate is 80°C / min, hold at 750°C for 8 minutes, and hold at 1300°C for 10 minutes to obtain the required titanium-aluminum-carbon ceramic block that can be etched in water, and put the obtained ceramic block into Al 2 o 3 Add an appropriate amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com