Preparation method of individualized 3D printed high tibial osteotomy guide plate

A 3D printing and osteotomy technology, used in bone drill guidance, medical science, surgery, etc., can solve the problems of difficulty in ensuring the accuracy of the osteotomy position, increasing the risk of postoperative infection for patients, and easily endangering the health of surgeons. The effect of shortening surgical anesthesia time, shortening operation time, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described in detail below in conjunction with the embodiments.

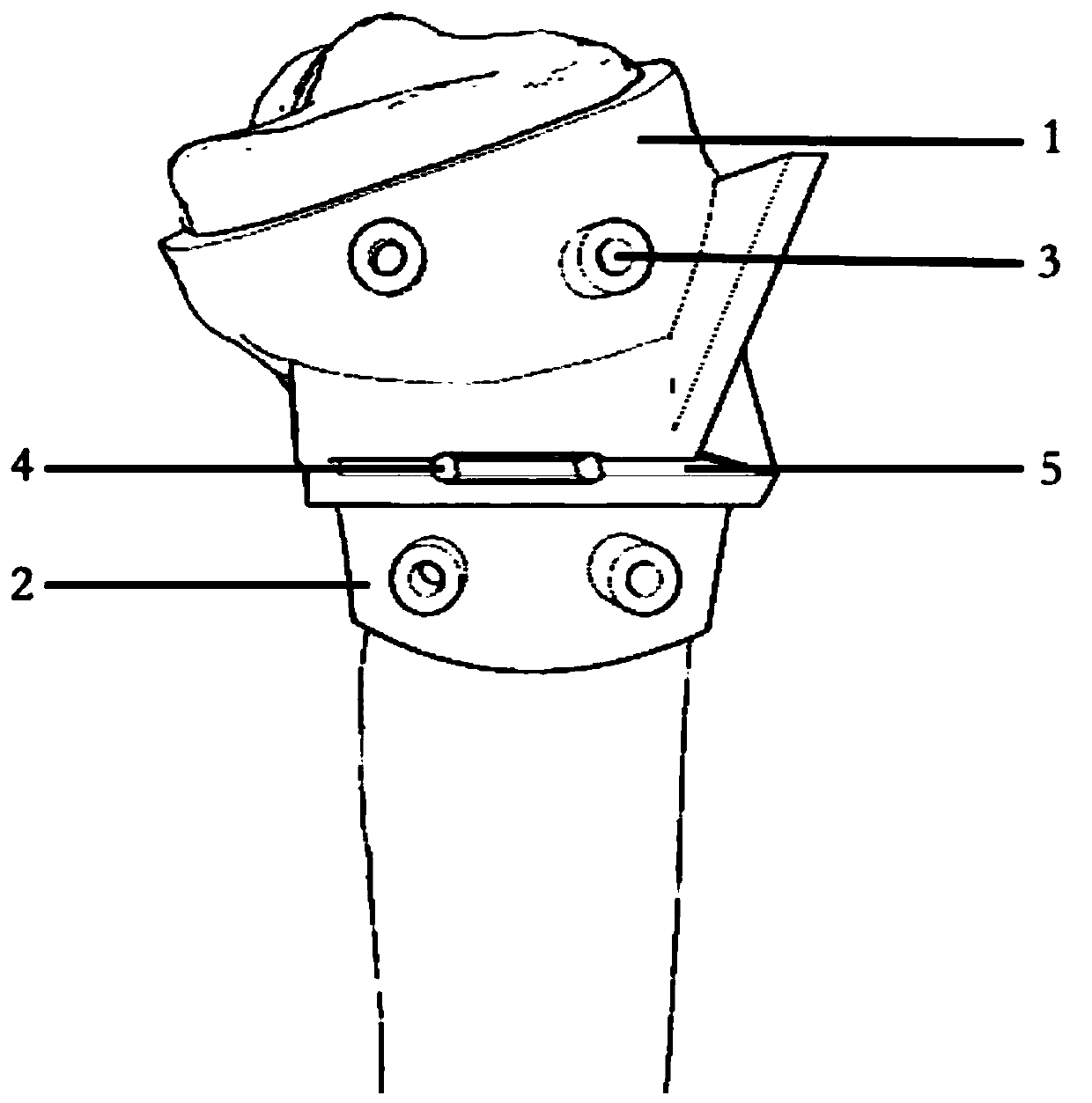

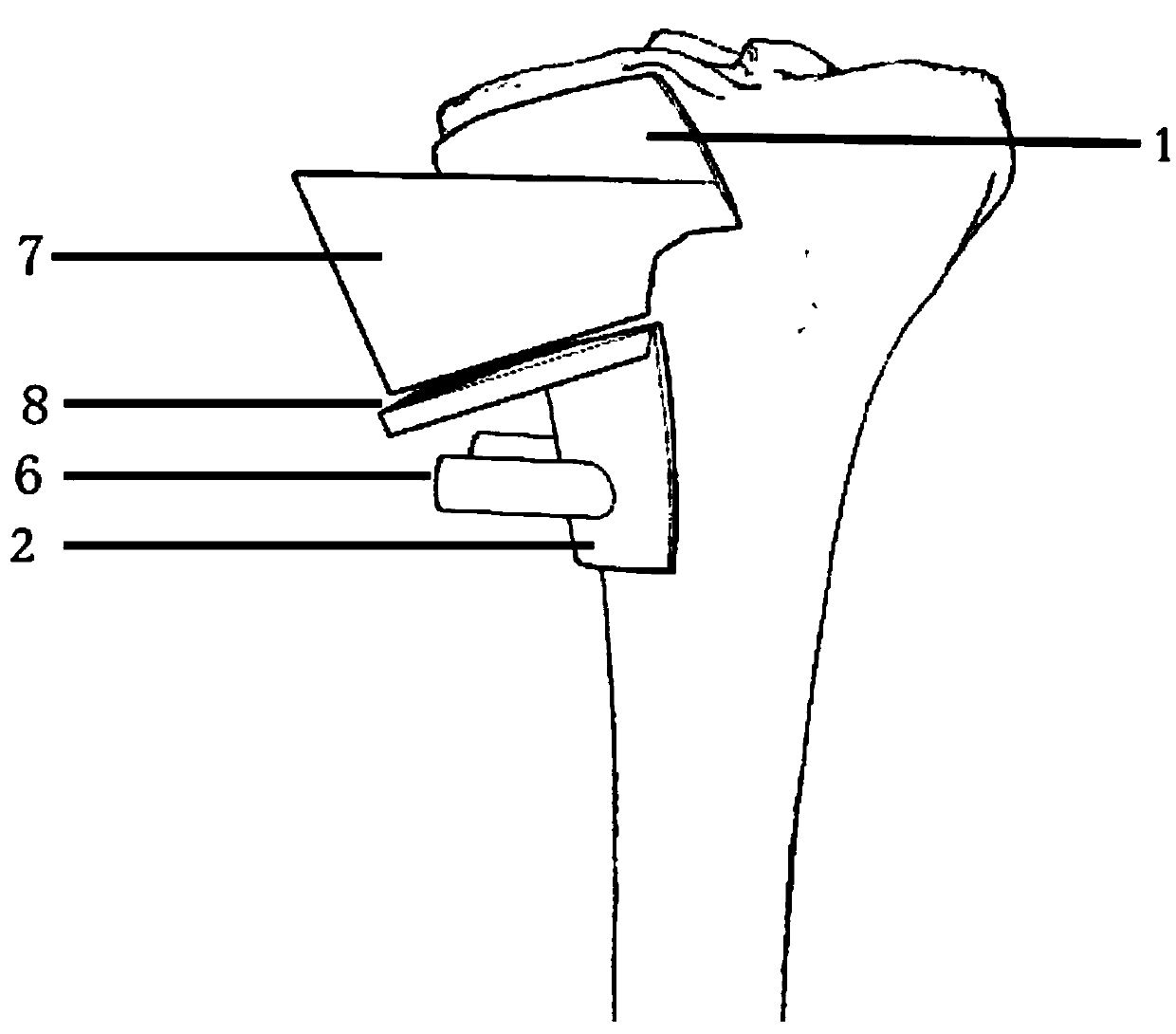

[0028] Such as figure 1 As shown, this embodiment provides an osteotomy guide plate for high tibial osteotomy. This osteotomy guide is designed in one-piece 3D printing. figure 1 The middle and upper plate body 1 and the lower plate body 2 are integrally connected; the positioning hole 3 at the proximal end of the tibia is the position where the osteotomy guide is fixed to the patient’s tibia with a 2mm diameter Kirschner wire, and the four fixing holes are short post holes It is quadrilateral and distributed parallel to the upper and lower plates; the Kirschner wire hole 4 of the guide is the initial stabilization device of the osteotomy guide plate for high tibial osteotomy, and it is a supplementary device for the positioning hole 3 at the proximal end of the tibia. Drive into the guide hole of the calibration shaft, and after the osteoto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com