Method for producing deuterium-depleted water and method for producing deuterium-concentrated water

A manufacturing method, the technology of deuterium-depleted water, applied in the field of deuterium-depleted water, can solve the problems of large economic burden and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〉

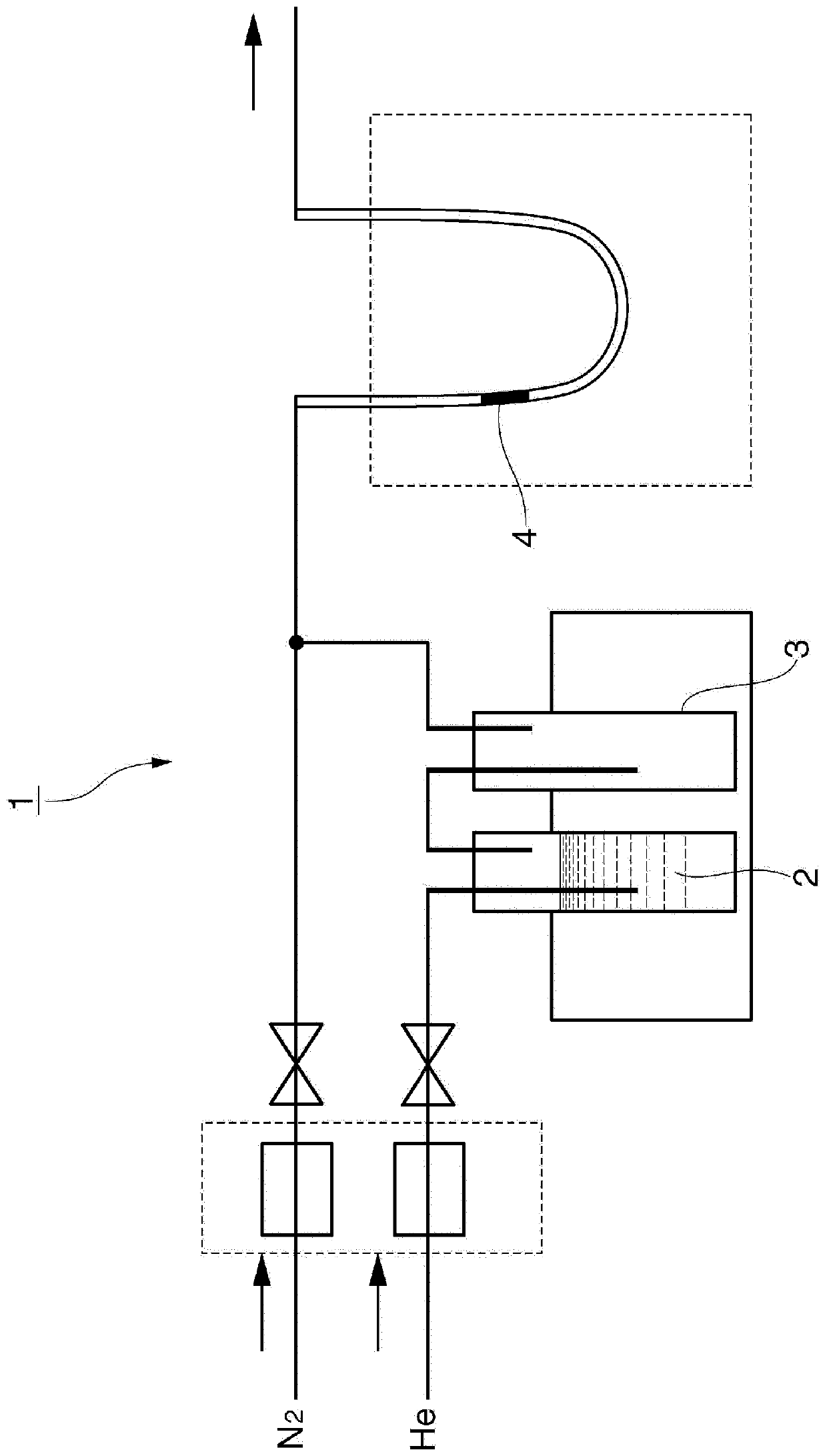

[0084] Such as Figure 4 As shown, the separation device 9 of the first embodiment has: a supply device 10 capable of separately supplying protium gas and flowing gas (nitrogen, helium), and passing the helium gas through the water 2 and the empty test tube 3 to supply water vapor. The steam generator 19 is built-in the adsorption tank 11 of the above-mentioned adsorbent material configured in such a way that water vapor or flowing gas passes through, the deuterium concentrated water outlet 12, and the deuterium-depleted water outlet 13 are respectively arranged in the pipeline of nitrogen gas and the pipeline of helium gas And mass flow controllers 17, 18, 20, and valves V1, V2, V3, V4 in the pipeline of protium gas.

[0085] In the first embodiment, first, when the valve V1 and the valve V2 are opened and the valve V3 is operated to open the deuterium concentrated water outlet 12, mass flow controllers 17 and 18 are used to flow from the supply device 10 to the adsorption ta...

no. 2 approach 〉

[0100] Such as Figure 5 As shown, the second embodiment is characterized by the use of a rotating adsorbent material 14 .

[0101] This separation device 9 has: a supply device 10 capable of supplying water vapor, protium gas, and flowing gas (nitrogen, etc.); 14, deuterium concentrated water outlet 12 and deuterium-depleted water outlet 13.

[0102] The adsorbent 14 is formed in a disk shape or a column shape, and is arranged so that the plane faces the upstream direction and the downstream direction.

[0103] In addition, it is divided into a route for supplying water vapor and flowing gas from the supply device 10 to the adsorbent 14, a route for supplying protium gas, and a route for supplying only dried flowing gas, and these supply ports are aligned along the circumferential direction of the adsorbent 14. configuration. The supply ports for mixed gas, protium gas and flowing gas remain stationary.

[0104] In the second embodiment, the mixed gas of water vapor and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com