An insulation drip tube and its purpose

A technology for drip tubes and uses, applied in the field of insulating drip tubes, to achieve the effect of no moving parts, no drive, and no control loop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

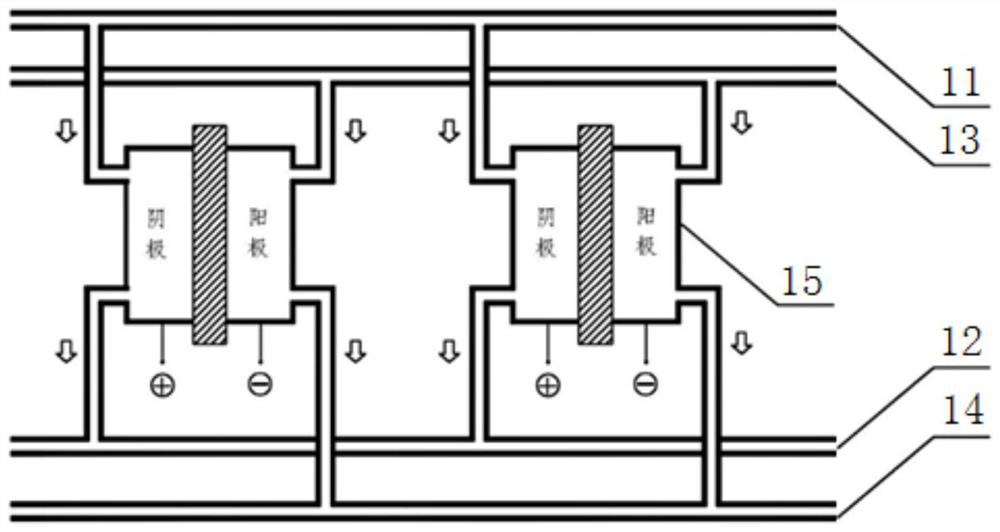

Image

Examples

Embodiment 1

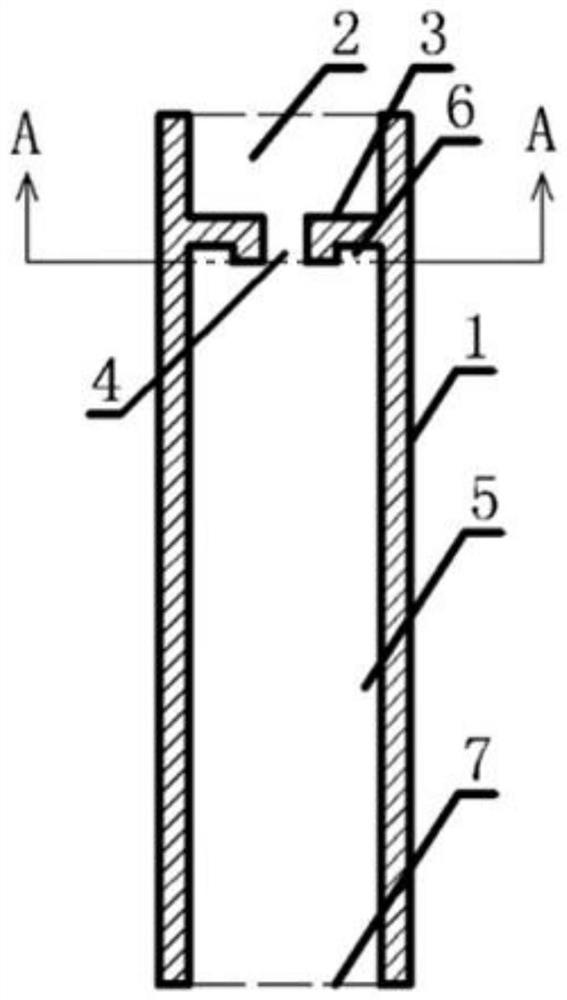

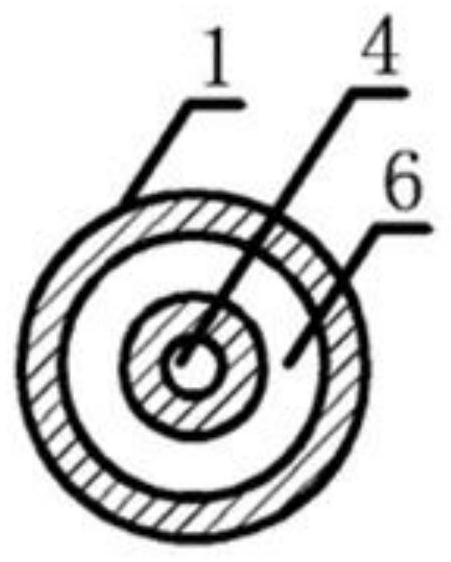

[0030] like figure 2 , 3 As shown, an insulating drip tube includes a tube body 1, and the tube body 1 is provided with a liquid inlet 2, a diaphragm 3, a lumen 5 and a liquid outlet 7 in sequence from top to bottom; the The diaphragm 3 is sealingly connected with the tube wall of the pipe body 1, and a drip hole 4 is arranged in the middle of the diaphragm 3, and the drip hole 4 communicates the liquid inlet 2 and the lumen 5. The outer circumference of the drip hole 4 A groove 6 is provided between the inner wall surface of the lumen 5 . The lumen 5 is filled with inert gas; the wall of the lumen 5 is made of insulating material.

[0031] In a further solution, the inner wall surface of the lumen 5 is coated with polytetrafluoroethylene. The inert gas includes nitrogen gas and argon gas, and the insulating material includes glass material, ceramic material, and polymer material.

[0032] In a further solution, the cross-sectional shape of the pipe body 1 is circular.

...

Embodiment 2

[0036] like Figure 4 , 5 As shown, an insulating drip tube includes a tube body 1, and the tube body 1 is provided with a liquid inlet 2, a diaphragm 3, a lumen 5 and a liquid outlet 7 in sequence from top to bottom; the The diaphragm 3 is sealingly connected with the tube wall of the pipe body 1, and four drip holes 4 are arranged in the middle of the diaphragm 3, and the four drip holes 4 are arranged in an array to form a drip hole array. A groove 6 is provided between the inner wall surfaces of the cavity 5 . The drip hole 4 communicates the liquid inlet 2 and the lumen 5; the lumen 5 is filled with inert gas; the cavity wall of the lumen 5 is made of insulating material.

[0037] In a further solution, the inner wall surface of the lumen 5 is coated with polytetrafluoroethylene.

[0038] In a further solution, the cross-sectional shape of the pipe body 1 is circular.

[0039]When the conductive liquid flows to the four drop holes 4 through the liquid inlet 2, nearly ...

Embodiment 3

[0042] like Image 6 , 7 As shown, an insulating drip tube includes a tube body 1, and the tube body 1 is provided with a liquid inlet 2, a diaphragm 3, a lumen 5 and a liquid outlet 7 in sequence from top to bottom; the The diaphragm 3 is sealingly connected with the tube wall of the pipe body 1, and a drip hole 4 is arranged in the middle of the diaphragm 3, and the drip hole 4 communicates the liquid inlet 2 and the lumen 5, and the lumen 5 is filled with water. There is an inert gas; the wall of the lumen 5 is made of insulating material.

[0043] In a further solution, the inner wall surface of the lumen 5 is coated with polytetrafluoroethylene.

[0044] A further scheme, a further scheme, the cross-sectional shape of the pipe body 1 is a rectangle, such as Image 6 , 7 As shown, the tube body 1 located on the two short sides of the rectangle is each provided with a groove 6, and the groove 6 is located between the outer circumference of the drip hole 4 and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com