Cooling fan and cooling device for electronic equipment and electronic equipment

A technology for electronic equipment and heat dissipation fans, applied in the fields of electrical digital data processing, instruments, calculations, etc., can solve problems such as damage, heat pipe deformation or destruction, and unstable operation, so as to ensure operational stability, set up a simple structure, and avoid system crash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

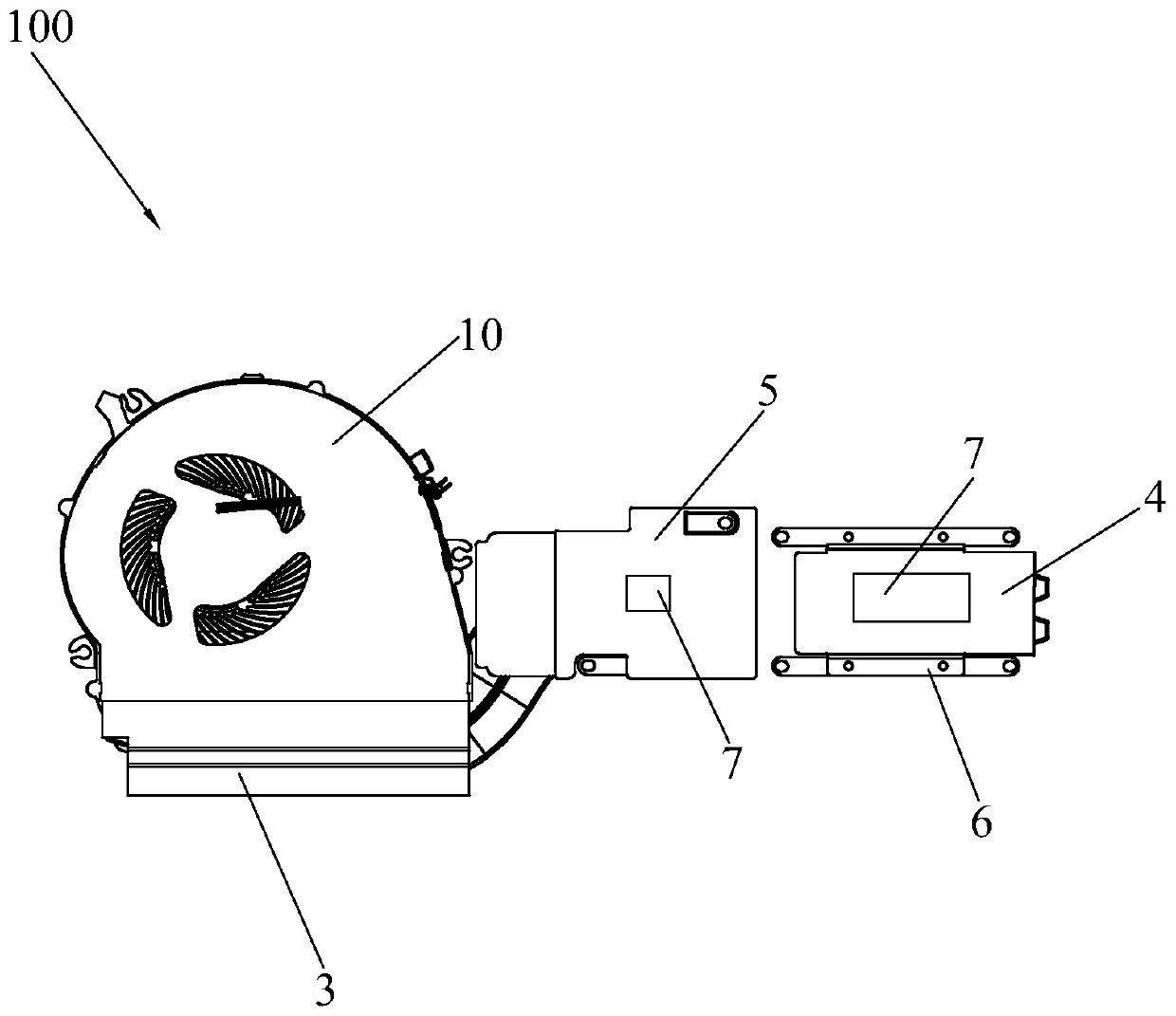

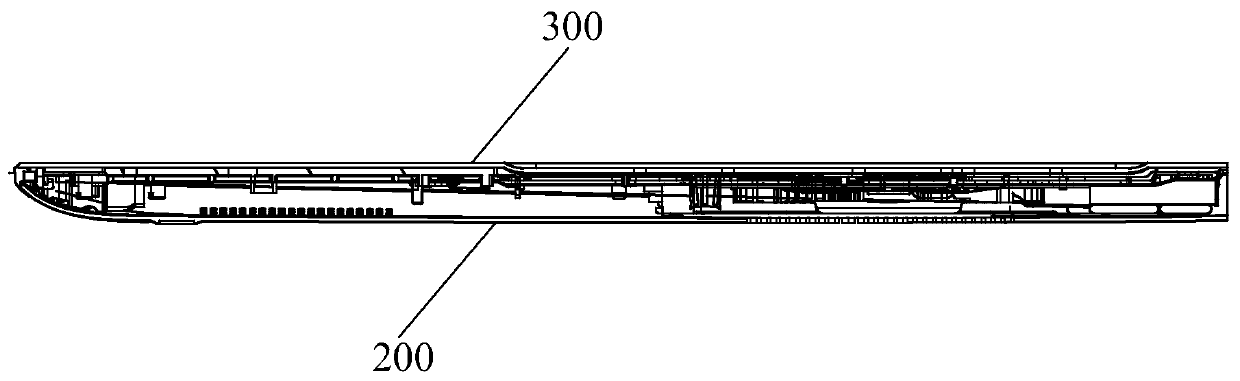

[0022] see Figure 1 to Figure 4 , the invention discloses a cooling fan 1 for electronic equipment, comprising a fan base 10, a fan cover 20 and a fan impeller 30, an air outlet 40 is formed between the fan base 10 and the fan cover 20, and the fan cover The body 20 includes a cover part 21 and an extension part 22 connected to an end of the cover part 21 close to the air outlet 40 . The extension part 22 is configured to be disposed between the heat pipe 2 of the electronic device and the bottom case 200 . Generally speaking, the protruding portion 22 has a sheet structure, but not limited thereto.

[0023] When the heat dissipation fan 1 of the present invention is used as a component of the heat dissipation device 100 when it is assembled in an electronic de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com