Low pressure pouring closing method for concrete grouped cracks

A technology for concrete and concrete surface, applied in the field of concrete, can solve the problems that affect the acceptance of new projects, unsatisfactory effects, etc., and achieve the effects of low repair cost, reliable crack sealing quality, and improved durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

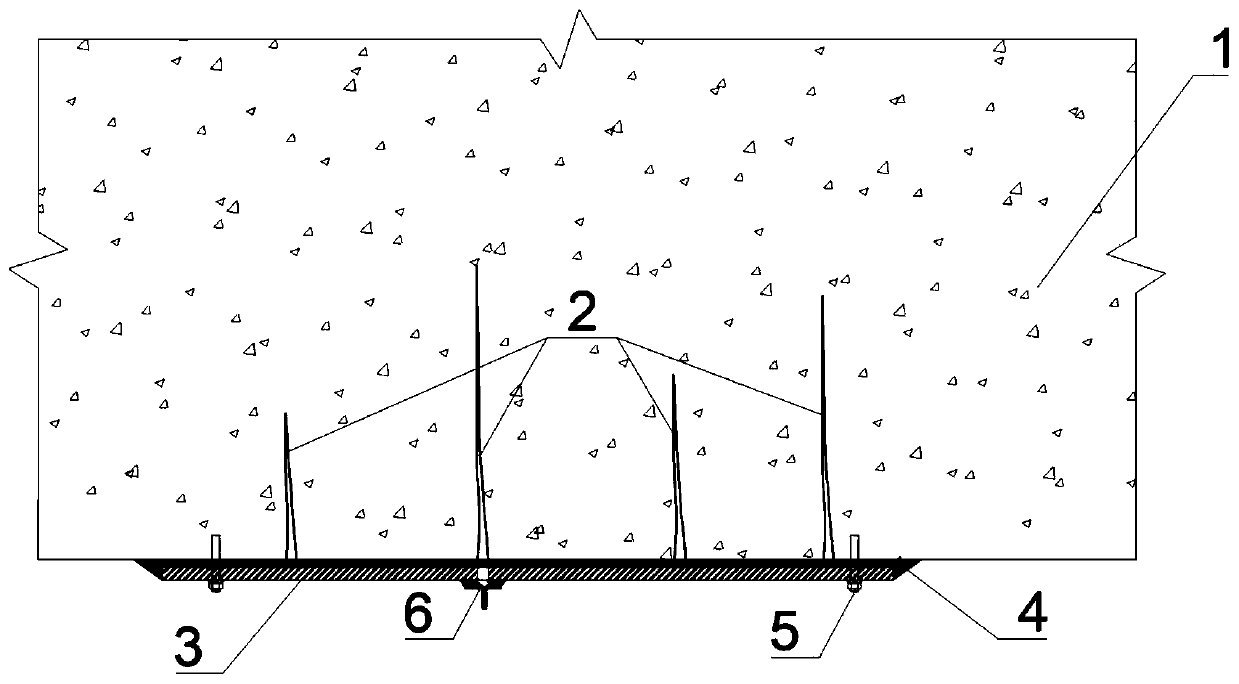

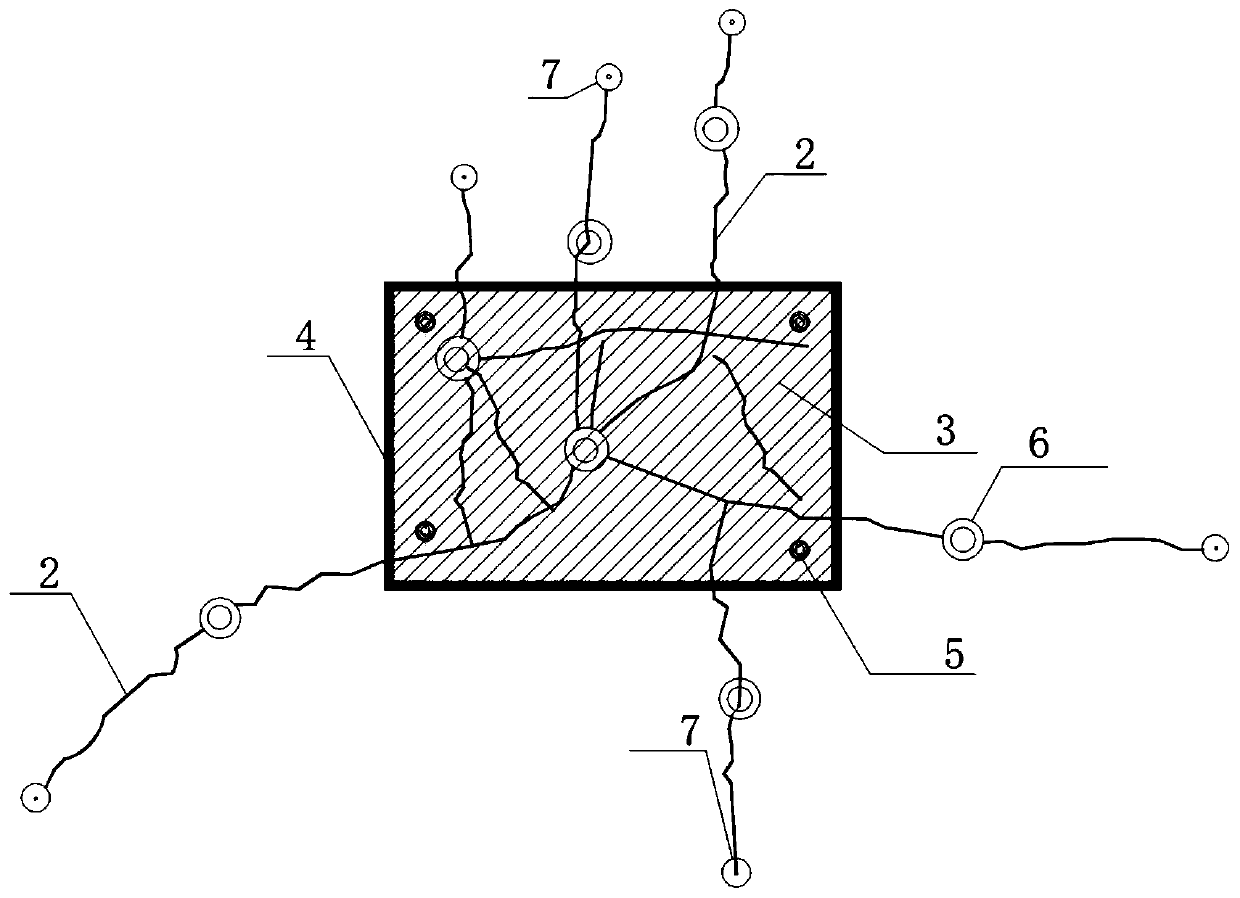

[0025] like Figure 1~2 Follow the steps below to repair the first group of cracks in the concrete to be repaired;

[0026] 1. Process the formwork 3, and process a suitable formwork 3 according to the range of group cracks on the surface of the concrete structure 1 to be repaired. The formwork 3 is a plate-like structure with a smooth surface, which can cover most of the group cracks, and is in a regular shape, which is convenient for final For fixed installation, reserve injection holes on template 3;

[0027] 2. Clean the surface of the concrete structure 1 to be repaired, use a grinding wheel, a wire brush or similar tools to remove the dirt, dust, etc. on the surface of the cracked area of the concrete group, that is, clean the concrete surface in the area covered by the template 3, and for the area covered by the template 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com