Mxene-PDMS composite foam with hollow structure, and preparation method and application of Mxene-PDMS composite foam

A composite foam, mxene-pdms technology, applied in the field of flexible wearable electronic devices and new materials, can solve the problems of insufficient sensing range, difficulty in mass production, cumbersome preparation methods, etc., to achieve high bending deformation capacity, high The effect of bending ability and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, implementation technical solutions and advantages of the present invention more clear and clear, the following explanations are specifically explained in conjunction with the accompanying drawings. It should be noted that the following explanations are only aimed at explaining the present invention, but not limiting the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

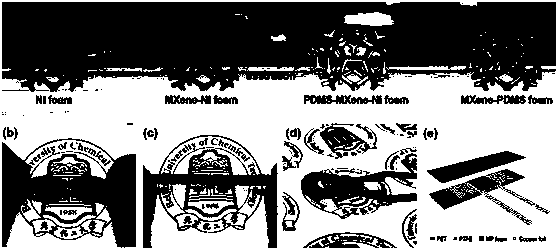

[0038] The invention adopts MXene-PDMS hollow foam as the active material of the sensor, preferably copper foil as the sensor electrode, and responds to a series of external pressures through electrical signals.

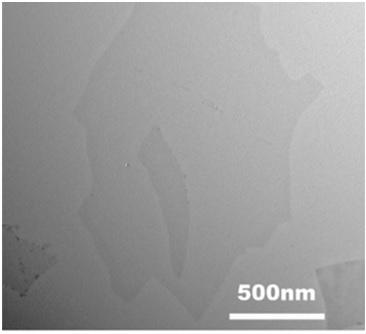

[0039] The MXene nanosheets in the present invention are obtained by selectively etching the precursor MAX phase with hydrochloric acid and lithium fluoride; the precursor MAX phase is prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com