Test method for simulating coarse aggregate-mortar weakened interface

A test method and technology of coarse aggregate, applied in the field of construction engineering, can solve the problems of amplification, large interference, low melting point of paraffin wax, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

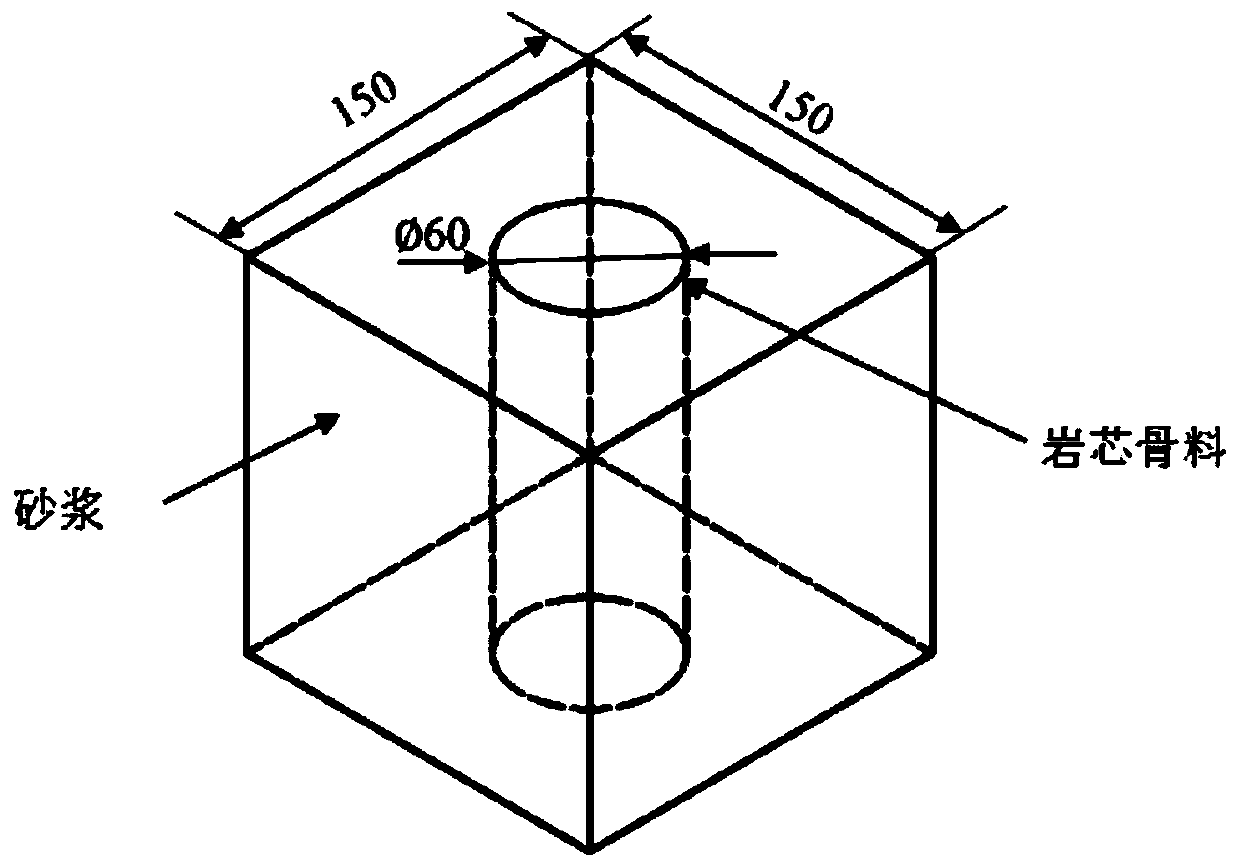

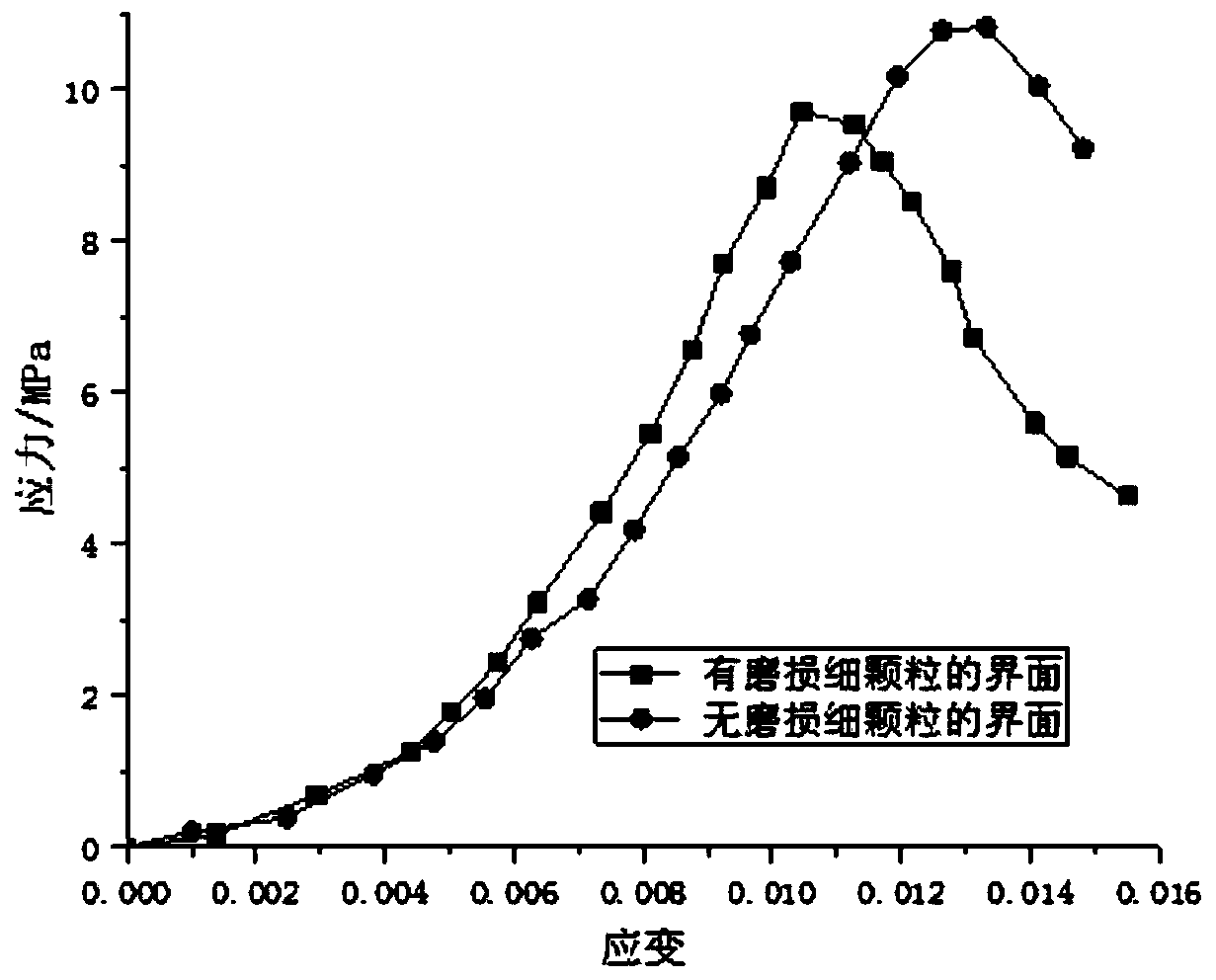

[0038] A kind of test method of simulating coarse aggregate-mortar weakening interface that the present invention proposes mainly includes following several parts: (1) drill core from natural hard rock, in order to simulate coarse aggregate; (3) pouring mortar, so that the mortar and core aggregate are combined to form a composite specimen of "interface specimen". (4) The composite specimen was loaded on a uniaxial testing machine to obtain the shear strength of the coarse aggregate-mortar interface. The bond stress of the interface can be obtained by dividing the load on the interface by the interface area. Combined with the relative displacement value of the interface and the core aggregate, the bond-slip characteristics of the coarse aggregate-mortar interface can be obtained.

[0039] The present invention will be described in further detail below through specific examples. The following examples can enable those skilled in the art to understand the present invention more...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com